Welding spark receiving tray

A fire plate and pallet technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as labor-intensive, difficult to ensure safety, and waste of materials, and achieve the effect of ensuring safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

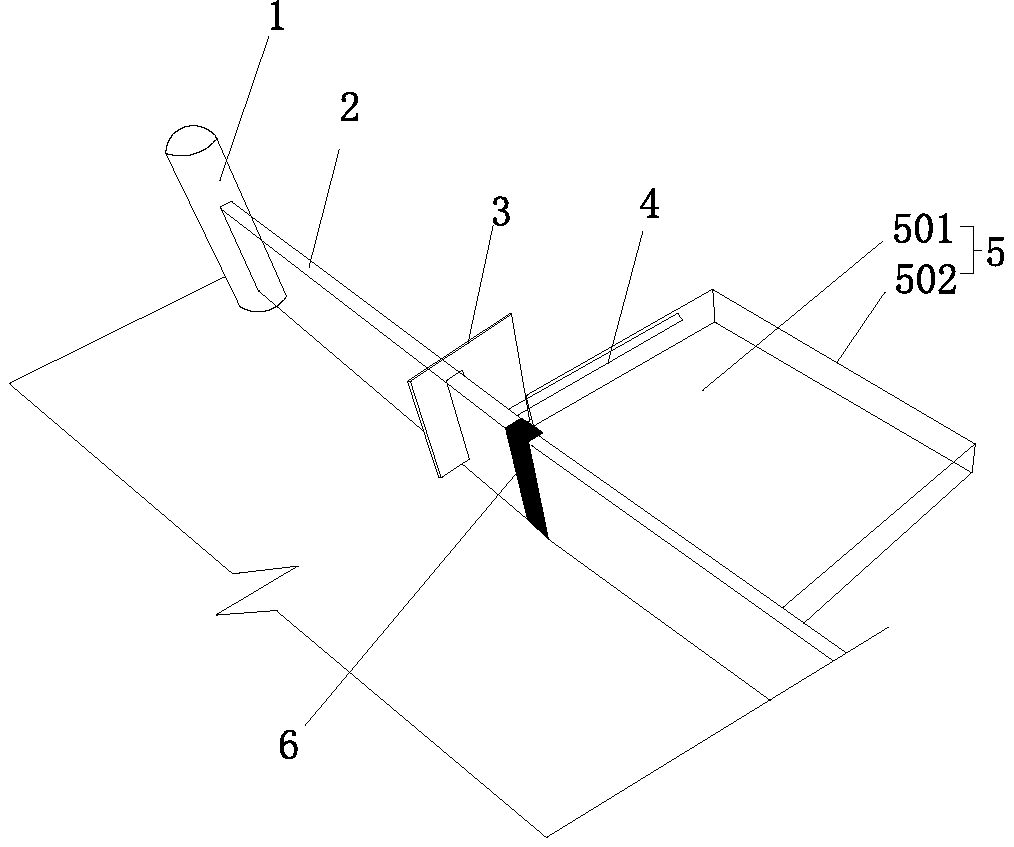

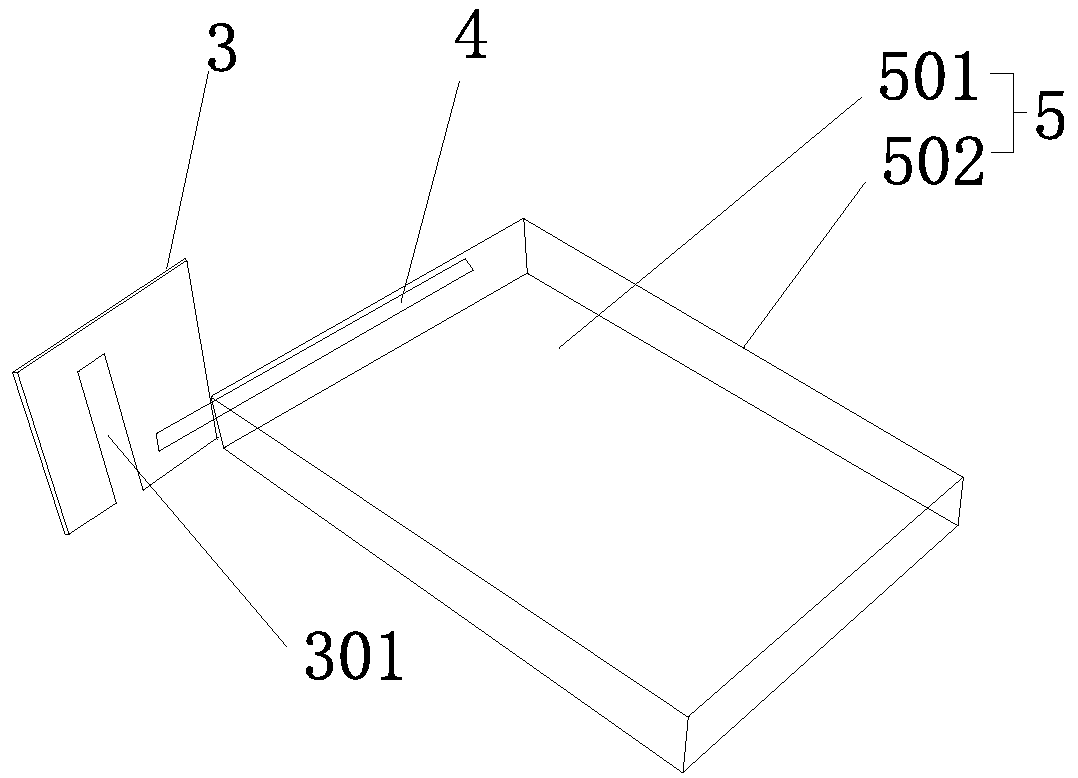

[0024] The invention provides a welding fire plate, such as figure 1 and figure 2 shown, including:

[0025] Clamping plate 3, which is flat, has a rectangular notch 301 on it, and the notch 301 is used to be clamped on the skirting board 2, and the skirting board 2 is fixed to the railing column 1;

[0026] A connecting rod 4, one end is fixedly connected with the clamping plate 3;

[0027] The tray 5 includes a bottom surface 501 and a side edge 502 surrounding the bottom surface 501 , the other end of the connecting rod 4 is fixedly connected to the side edge 502 , and the bottom surface 501 is perpendicular to the clamping plate 3 .

[0028] Clamp the fire tray on the skir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com