Automobile part pneumatic punching machine

A technology of auto parts and pneumatic punching machines, which is applied in metal processing and other fields, and can solve the problems of heavy repetitive workload, low efficiency, defective products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

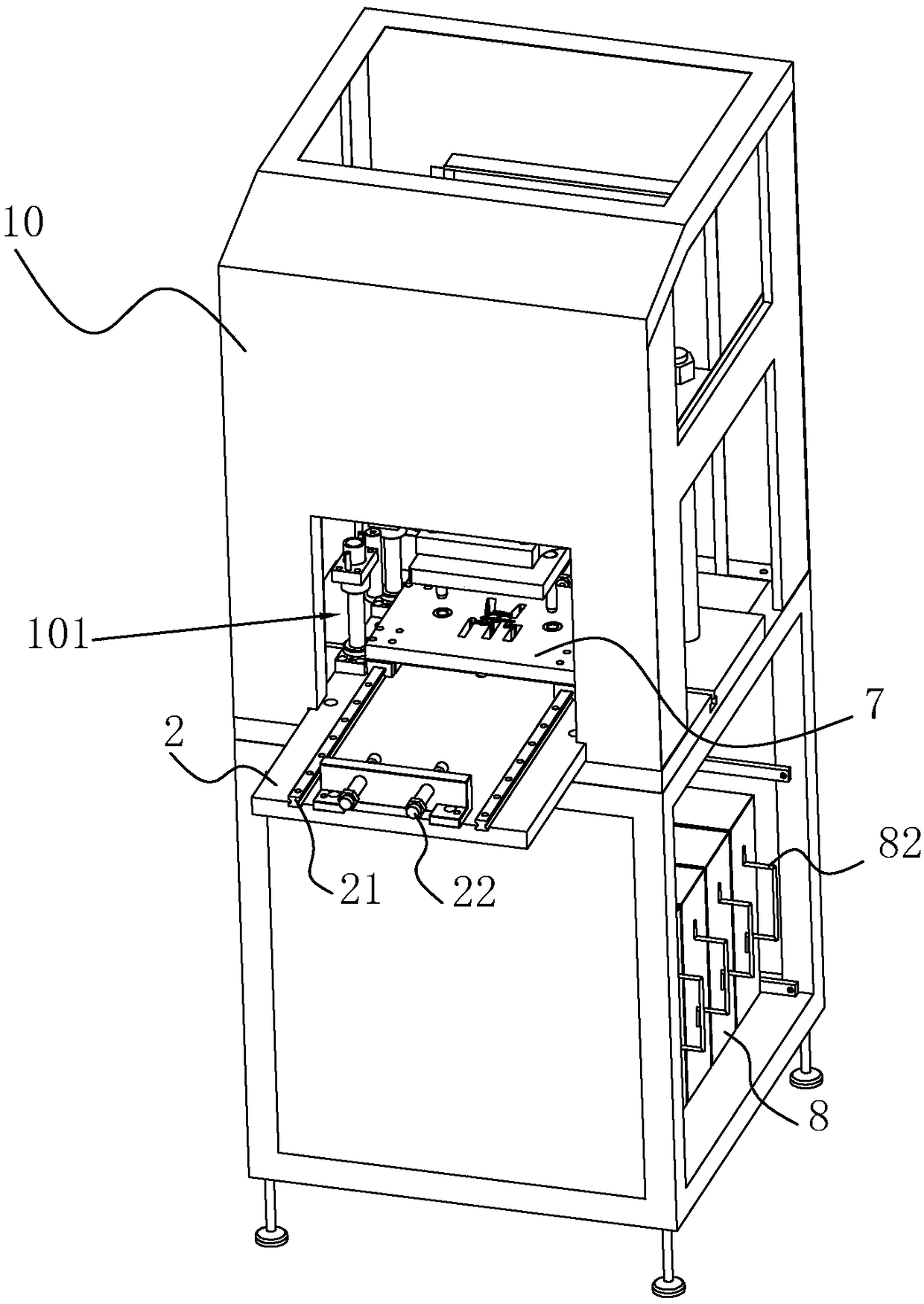

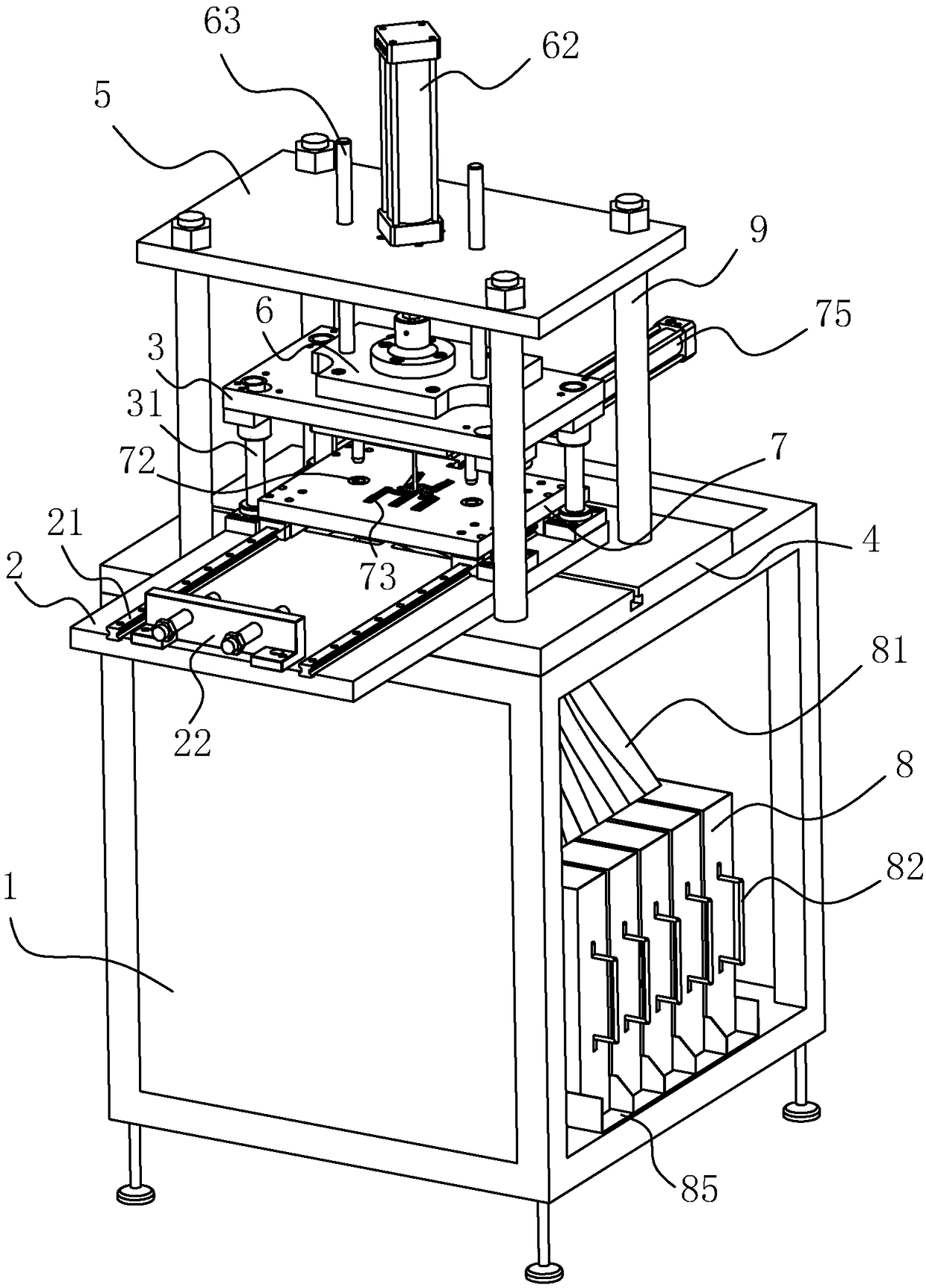

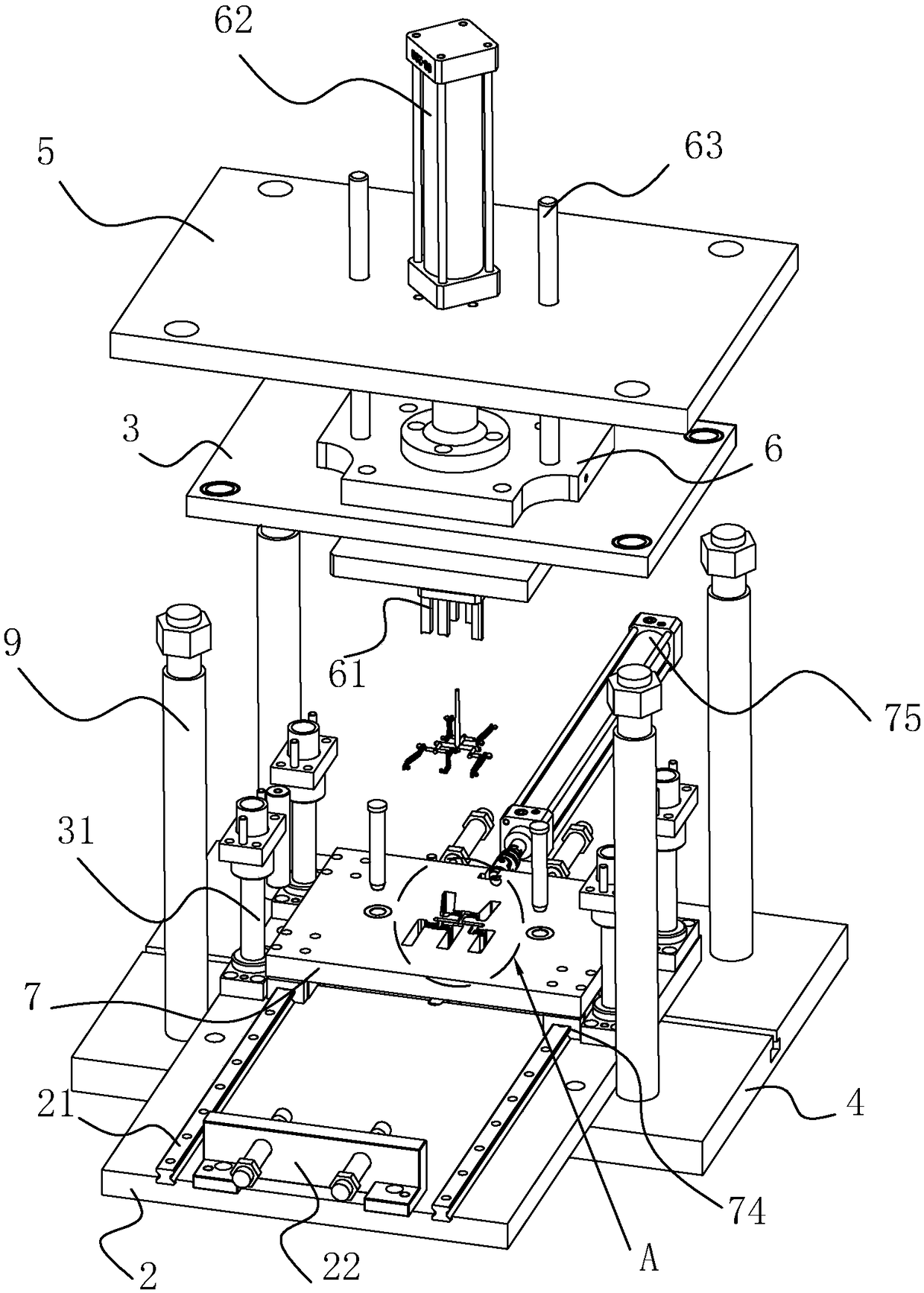

[0036] A pneumatic punch press for auto parts, refer to figure 2 , including a base 1, a lower formwork 4 is fixedly installed above the base 1, an upper formwork 5 is arranged directly above the lower formwork 4, and four fixed rods 9 are used for support between the upper formwork 5 and the lower formwork 4, and the four fixed rods 9 is fixedly connected between the upper formwork 5 and the lower formwork 4, and supports and fixes the overall skeleton formed by the upper formwork 5 and the lower formwork 4.

[0037] refer to image 3 and Figure 4 , the upper end of the upper template 5 is provided with a stamping cylinder 62, the stamping cylinder 62 is fixedly connected with a punching die upper plate 6, and the lower part of the punching die upper plate 6 is fixedly installed with an upper die punch 61 matching the shape of the auto parts to be processed; Cooperating with the punch 61 of the upper die, the lower die plate 4 is provided with a lower plate 7 of the die, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com