A brick transporter

A technology for transporting vehicles and bricks, which is applied in the direction of transporting objects, transporting and packaging, and vehicles for freight transportation, etc., can solve the problems of high labor intensity, affecting the efficiency of vehicle transportation, and slow speed, so as to improve transportation efficiency and reduce manpower. The effect of resource output and transportation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

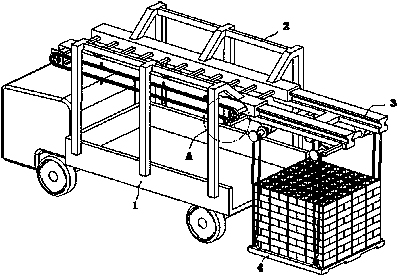

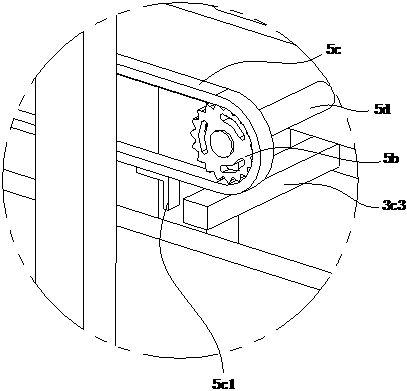

[0029] Embodiment one of the present invention: according to Figure 1 to Figure 7 The brick transporter includes a transporter body, a vehicle body 1 is provided on the rear side of the transporter body, and a support frame 2 is erected on the vehicle body 1, and the bottom of the support frame 2 is located at the bottom of the vehicle body 1. A lifting device 3 is provided above, and the lifting device 3 is slidingly matched with the support frame 2, and a driving mechanism is provided on one side of the support frame 2, and the driving mechanism is connected to the lifting device 3 for driving the lifting device 3 at the front end of the bucket 1. The upper position of the bucket 1 and the suspended position on the rear side of the bucket 1; the brick transport vehicle also includes a loading plate 4 for stacking bricks, and the lifting device 3 includes four vertically suspended The hook 3a and the lifting device 3 also include two synchronously rotating support shafts 3b,...

Embodiment 2

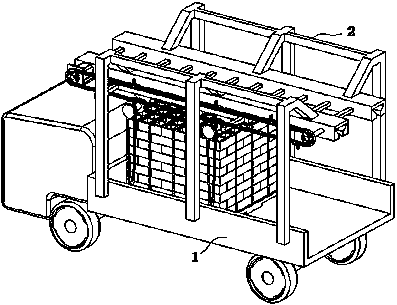

[0040] Embodiment 2 is on the basis of Embodiment 1, and additional traverse device is added, and the components in the corresponding embodiment 1 should be correspondingly refitted corresponding to the traverse device. In the case of a large width and a large width, the bricks can be neatly stacked into multiple rows through the traversing device to maximize the use of the space of the bucket 1.

[0041] The traverse device includes a screw mandrel 6a fixed on the top of the support frame 2 and several guide rods spaced apart from the screw rod 6a and arranged in parallel. The traverse device also includes a slide table 6b, which is fixed on several guide rods. On the support structure, the slide table 6b is connected to the screw rod 6a by transmission, and one end of the support frame is provided with a screw motor 6c that drives the screw rod 6a to rotate, and the screw motor 6c drives the screw rod 6a to rotate so as to drive the slide table 6b to move laterally .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com