Polypropylene complex resin composition for low-temperature injection molding

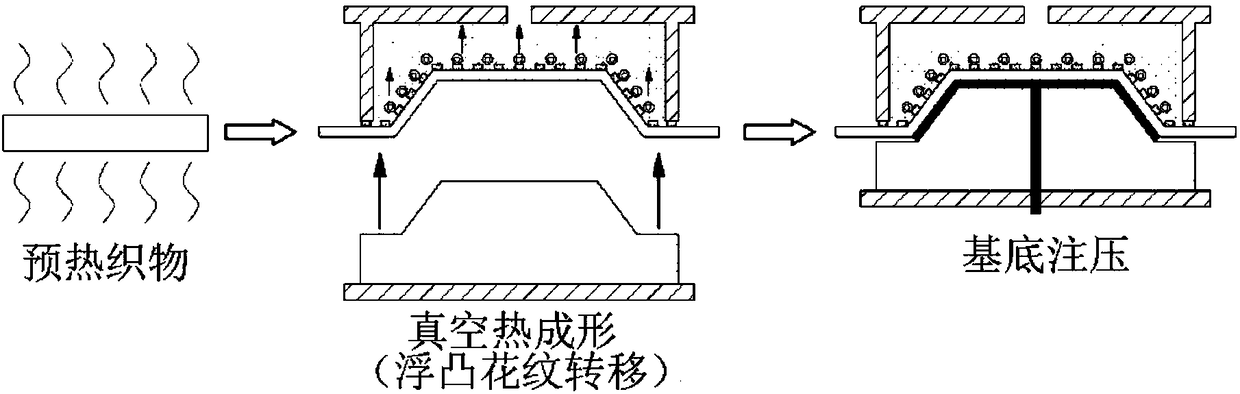

A polypropylene resin, composite resin technology, used in synthetic resin layered products, applications, household components, etc., can solve the problems of pre-formed fabrics that cannot be preheated, air bubbles, and poor quality, and achieve excellent moldability, The effect of process simplification and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

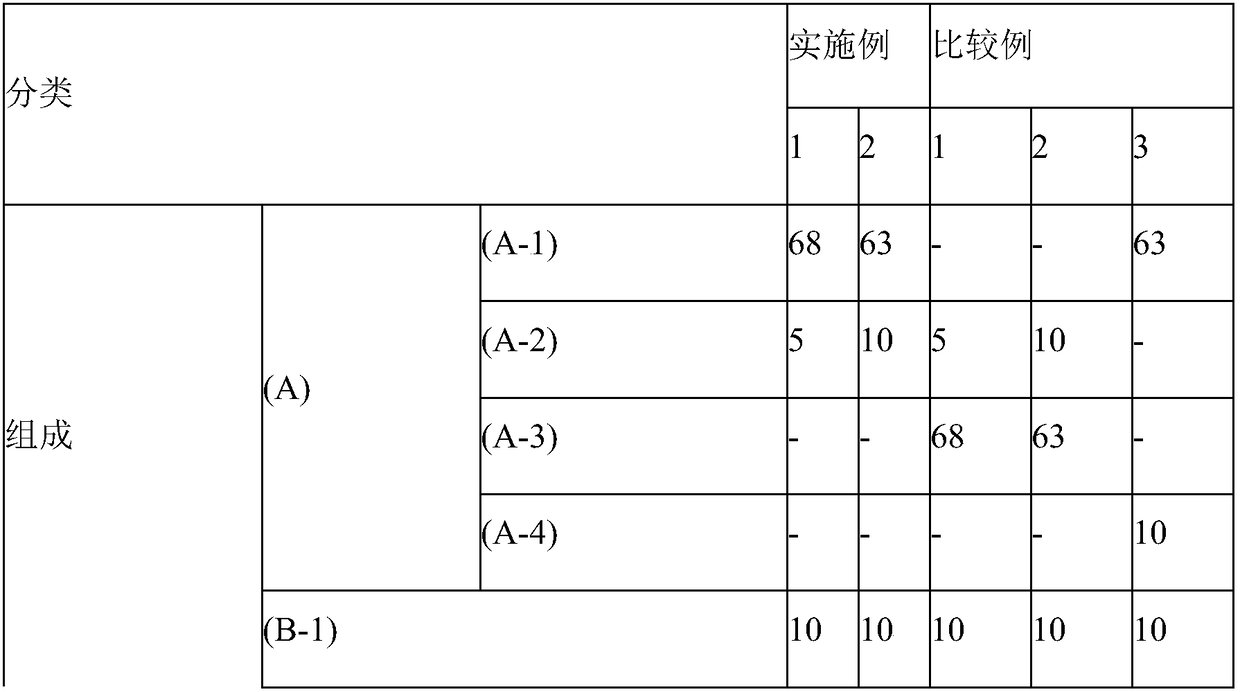

[0049] The following examples illustrate the invention but are not intended to limit it.

[0050] A polypropylene composite resin composition was prepared by blending the composition components at the content ratios shown in Tables 1 and 2 below.

[0051] At this time, the components of the composition used were as follows. In addition, samples were prepared from the prepared polypropylene composite resin composition, and physical properties were measured by the following methods for measuring physical properties.

[0052] composition components

[0053] polypropylene resin

[0054] (A-1) Highly crystalline ethylene-propylene copolymer (an isotactic index of 98% to 100%; 2.16 kg at 230° C., an MI value of 30 g / 10 min; an ethylene content of 3 to 7% by weight)

[0055] (A-2) Ultra-high fluidity homopolypropylene (2.16kg, at 230°C, MI value is 1200g / 10min; PDI value is 2 to 4)

[0056](A-3) Ethylene-propylene copolymer (isotactic index is 94% to 97%; 2.16kg, at 230°C, MI val...

Embodiment 3 to 7

[0087] These examples are provided in order to demonstrate that obtained by selectively adding (B) an olefin-based elastomer and (C) an inorganic reinforcing agent to (A) a polypropylene hybrid resin as components contained in a polypropylene composite resin composition Effect.

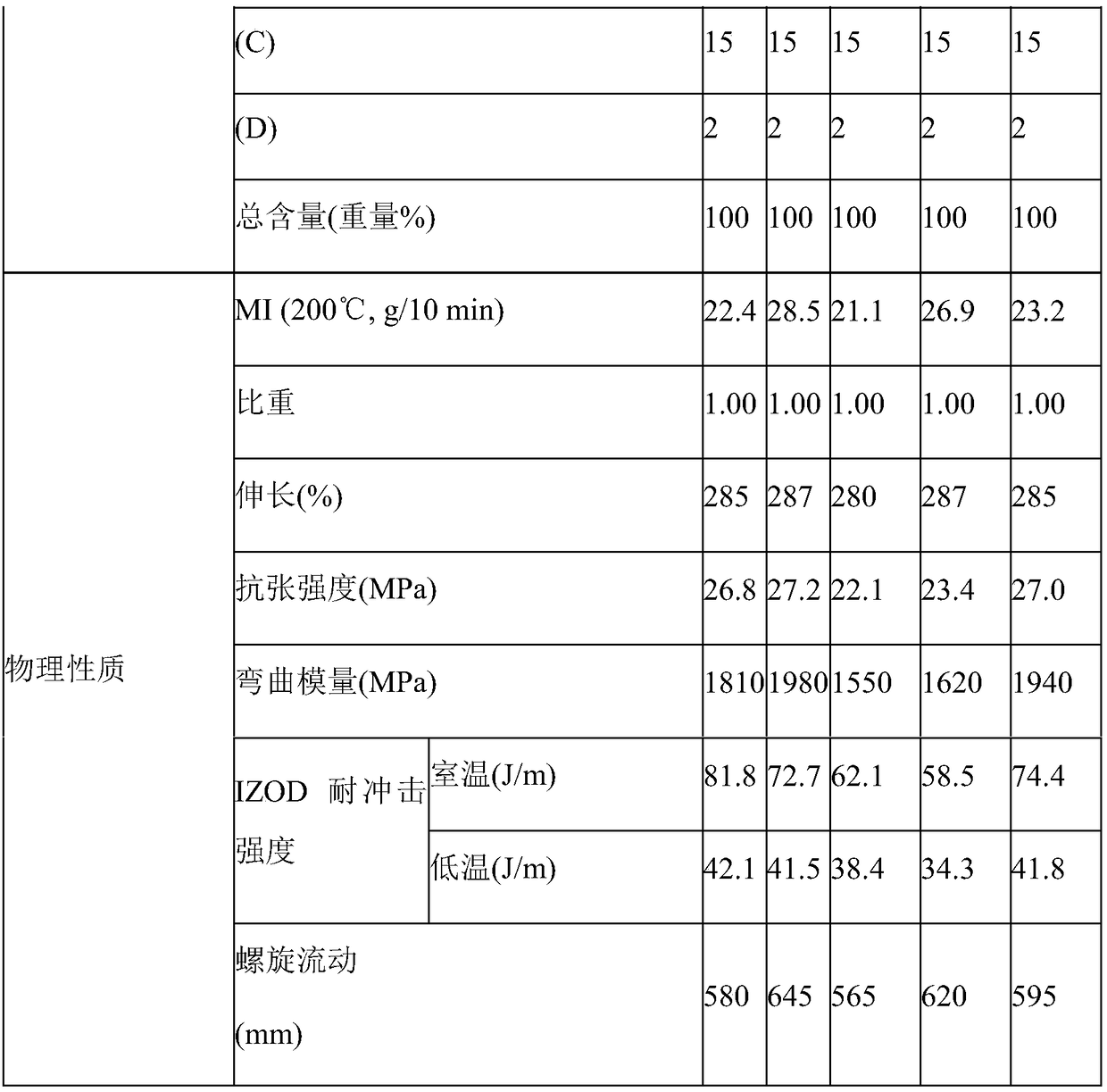

[0088] [Table 2]

[0089]

[0090]

[0091] From the results in Table 2, it can be confirmed that, in the case of the polypropylene composite resin compositions containing the smaller layered talc having a particle diameter of 3 to 6 μm as the (C) inorganic reinforcing agent of Examples 3 to 5, compared to With the composite resin composition of Example 2, the effect of improving physical properties such as tensile strength and impact resistance was obtained.

[0092] It can also be determined that in Examples 6 and 7 selectively use 1+4 In the case of ethylene-octene rubber (EOR) with a low Mooney viscosity (ASTMD1646) as the polypropylene composite resin composition of (B) olefin-based elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com