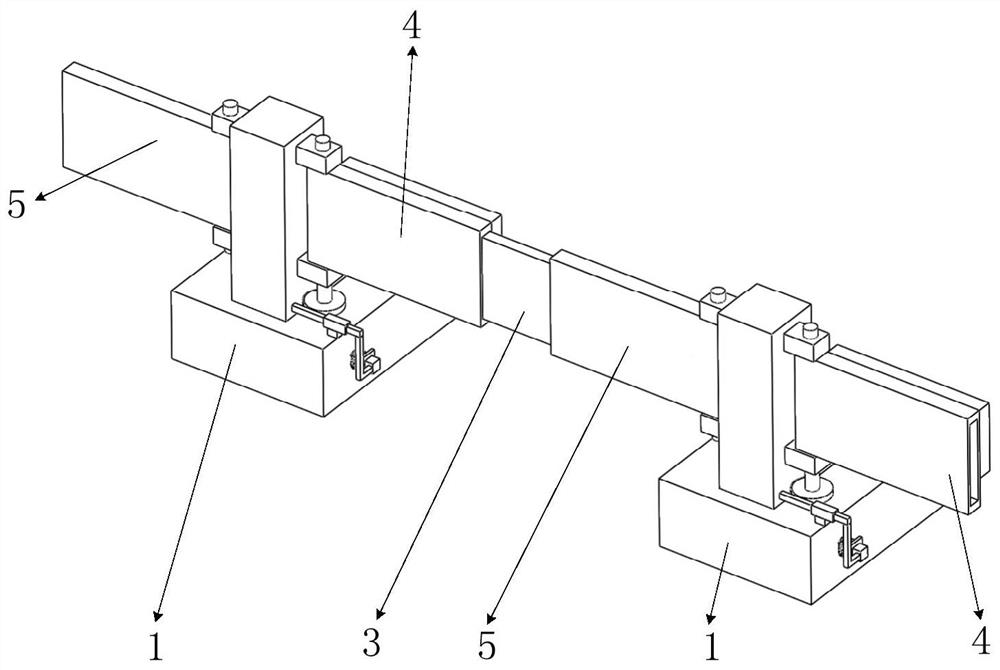

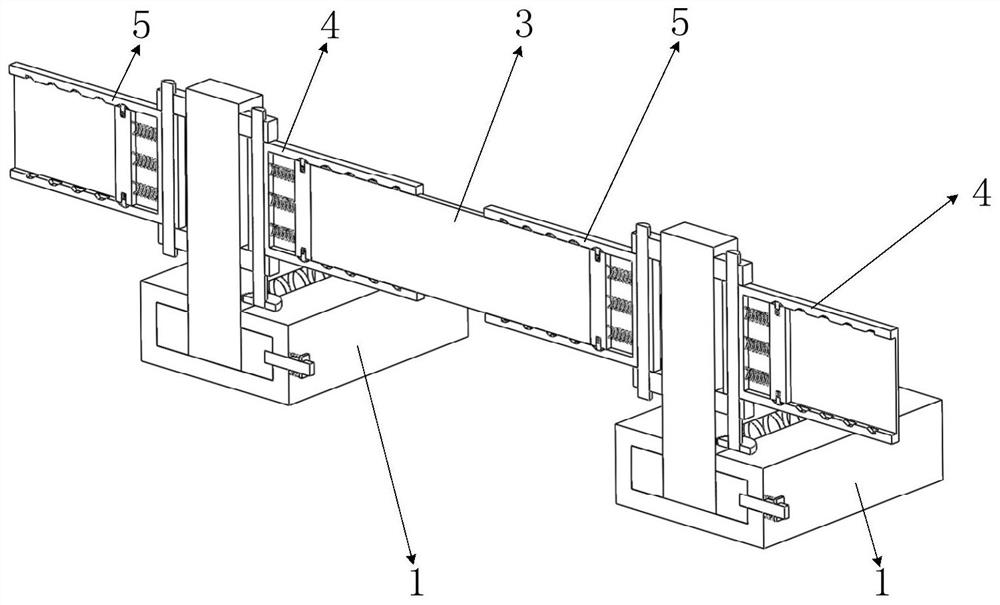

A buffered highway guardrail

A technology for highways and guardrails, applied to roads, roads, road safety devices, etc., can solve problems such as difficult restoration of guardrails, troublesome maintenance of guardrails, and affecting the overall appearance of expressway guardrails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

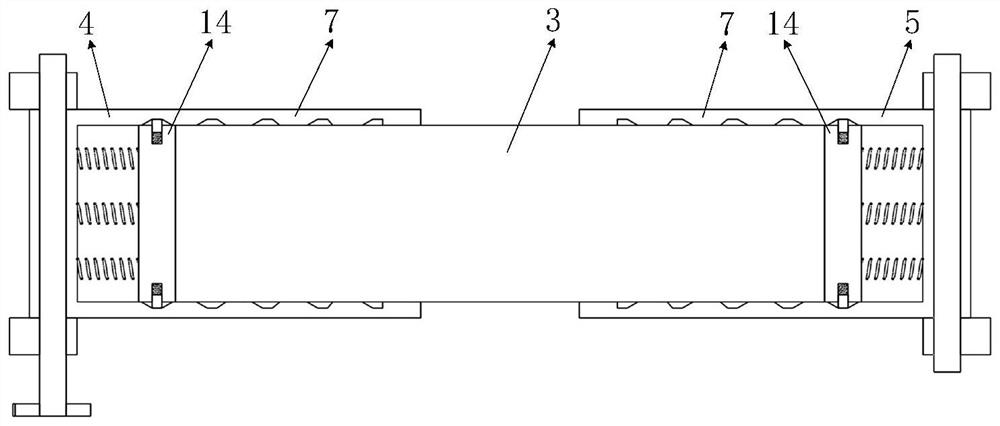

[0069] Specific embodiments: the base 35 of the guardrail mechanism 1 in the present invention is all fixedly installed on the roadbed of the expressway. When the pendulum plate 7 and the elastic steel plate 3 between the guardrail square posts 32 of two adjacent guardrail mechanisms 1 were not bumped, the pendulum plate 7 and the guardrail square post 32 became vertical state, and the leaf spring 23 was not compressed, and the first The spring 13 is not stretched, and the buffer slider 19 on the fixed steel plate slider 14 is located in the trapezoidal groove 15 farthest from the opening of the steel plate slider sliding groove 12 among the five trapezoidal grooves 15, and the second spring 18 is not pressed. During compression, the end of the buffer slider 19 away from the second spring 18 passes through the buffer slider sliding groove 20; The tooth bar 26 is engaged; the guide block spring 39 is not compressed, the limit groove 38 of the guide block 40 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com