Launching system with water spray suppression peripheral, high jet noise function

A technology of launching system and noise reduction system, which is applied to rocket launchers, offensive equipment, weapon types, etc., can solve the problems of strong peripheral noise, high sound pressure, and the effect of cooling and noise reduction cannot be radiated, so as to suppress loud noise, The effect of suppressing peripheral noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

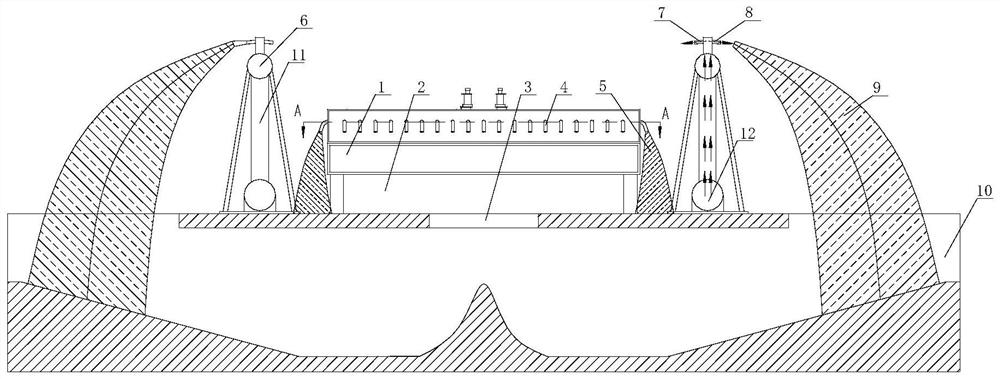

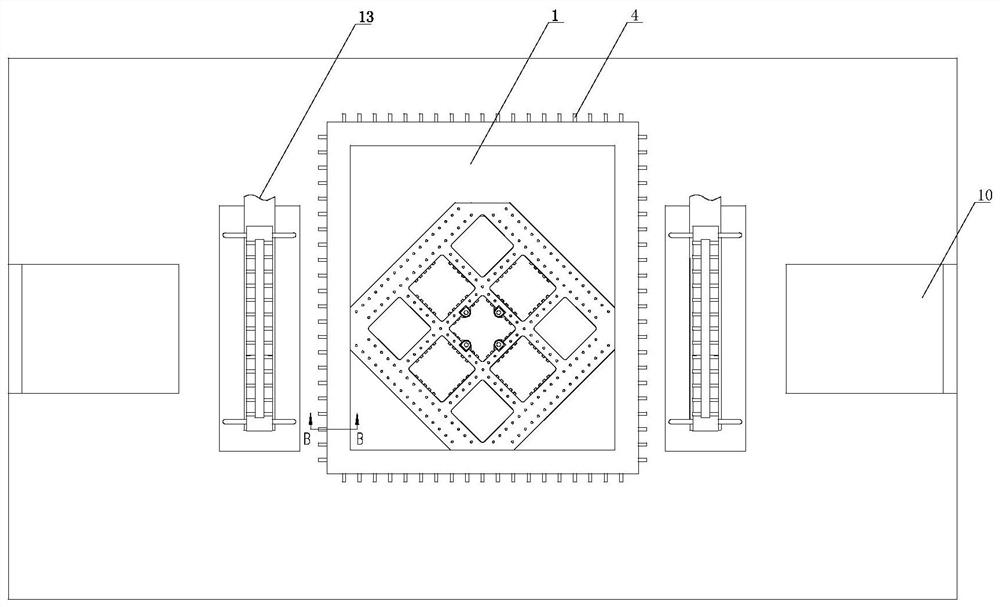

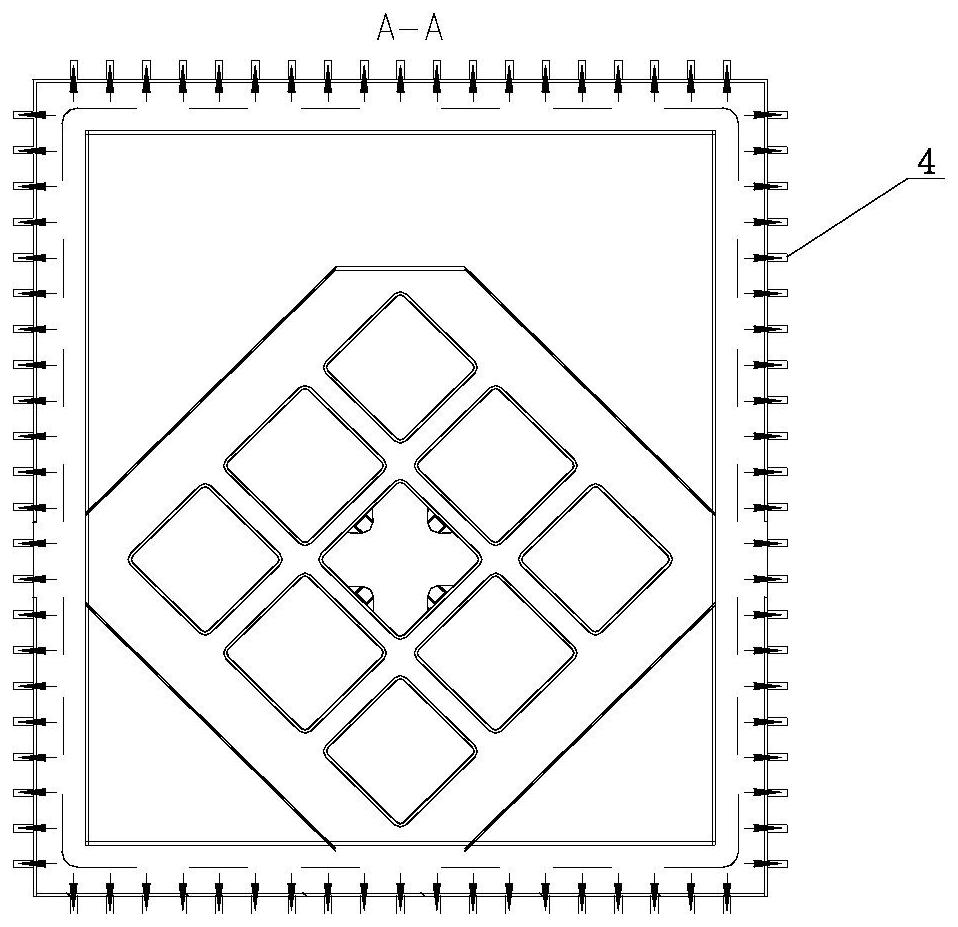

[0029] The invention aims at developing a launch system with the function of water spraying to suppress peripheral high-level jet flow noise. Design a first-level peripheral water spray noise reduction system that sprays water to the periphery on the launch platform body, and design a second-level high-level water spray noise reduction system around the launch platform, so as to reduce the noise intensity of rocket launch jets and suppress flow diversion through the launch platform The jet flow noise source area where the hole cascades back and splashes and the peripheral noise influence range formed by the gas flow ejected from the outlet of the diversion groove.

[0030] Such as figure 1 and figure 2 As shown, the first-level peripheral water spray noise reduction system can spray water from the launch platform body 1 to the side wall to the periphery, and suppress the high-intensity jet flow noise that descends and splashes through the launch platform body 1 diversion gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com