A Method for Measuring and Correcting Liquid Film Thickness of Gas-liquid Two-phase Annular Flow in Circular Pipe

A technology of liquid film thickness and annular flow, applied in measurement devices, instruments, and optical devices, etc., can solve the problems of expensive optical measurement equipment, complicated operation process, and strict requirements on the cleanliness of the measured medium and application environment. , to achieve the effect of low cost, simple operation and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is described in further detail below in conjunction with accompanying drawing:

[0069] refer to Figure 1a to Figure 4b , the method for measuring and correcting the thickness of the gas-liquid two-phase annular flow liquid film in the circular tube of the present invention comprises the following steps:

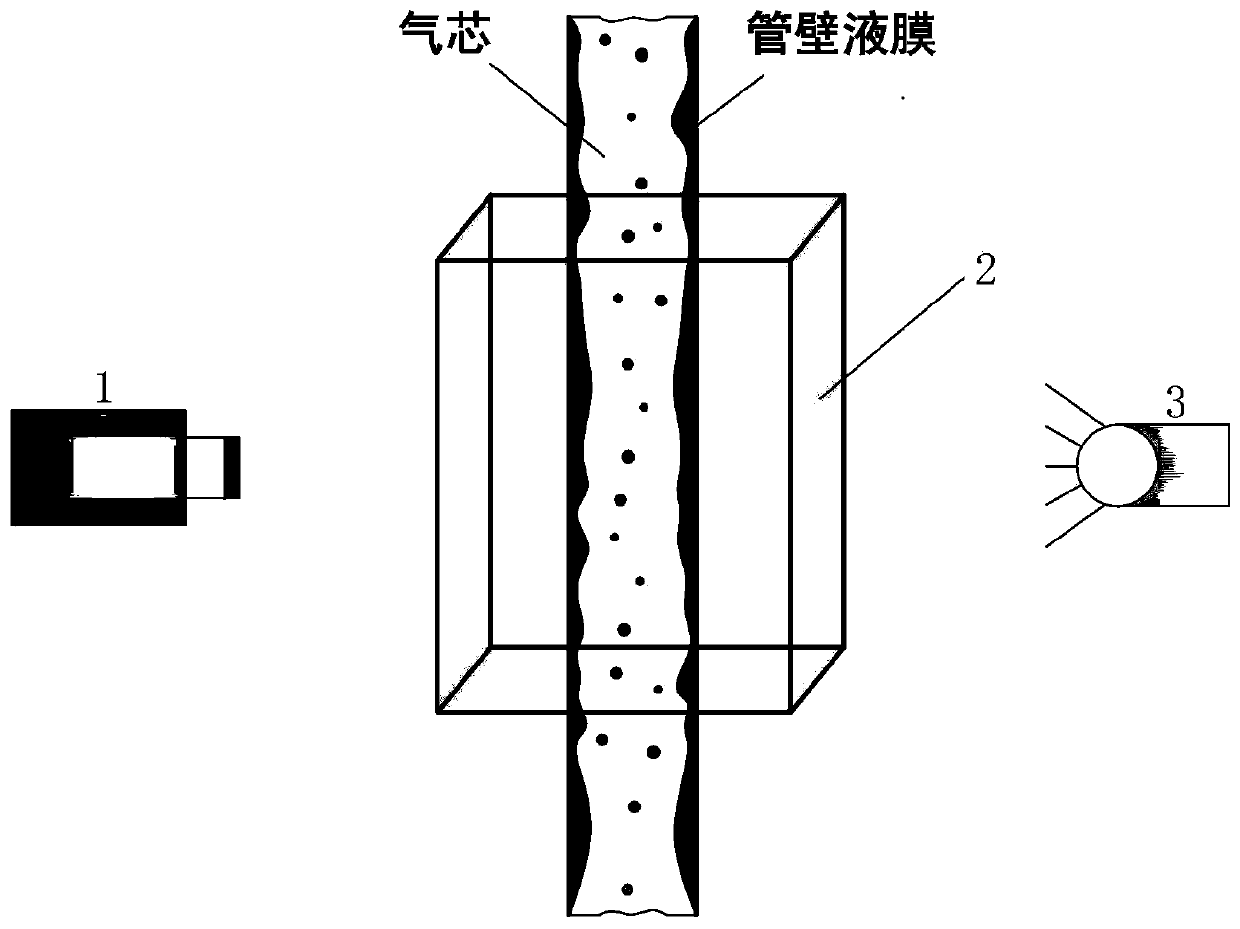

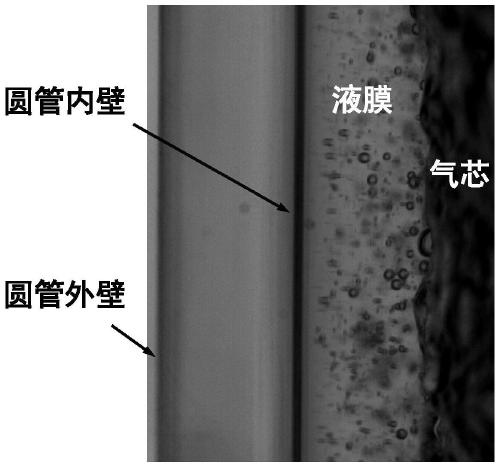

[0070] 1) Arrange a rectangular transparent water tank 2 outside the measuring section of the circular tube, install a photographic device 1 and a light source 3 on the front and back of the rectangular transparent water tank 2 respectively, turn on the light source 3, and use the photographic device 1 to photograph the gas-liquid two-phase annular shape in the circular tube The image of the fluid phase interface must include grayscale images of the tube wall, liquid film and gas core;

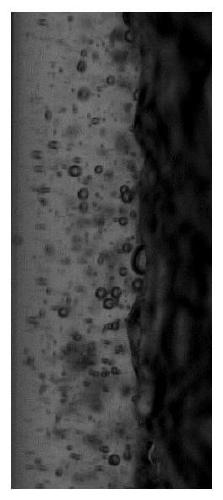

[0071] 2) Carry out digital image processing to the grayscale image that step 1) obtains, must comprise the binarization image of liquid film and gas core;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com