A method of measuring the thickness and flow of the two ring -shaped flow fluid membranes in the vertical tube

A measurement method and technology of liquid film thickness, applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve problems such as disturbance, measurement deviation, etc. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is described in further detail below in conjunction with accompanying drawing:

[0048] refer to figure 2 and image 3 , the measuring method of gas-liquid two-phase annular flow liquid film thickness and flow rate in the vertical pipe of the present invention comprises the following steps:

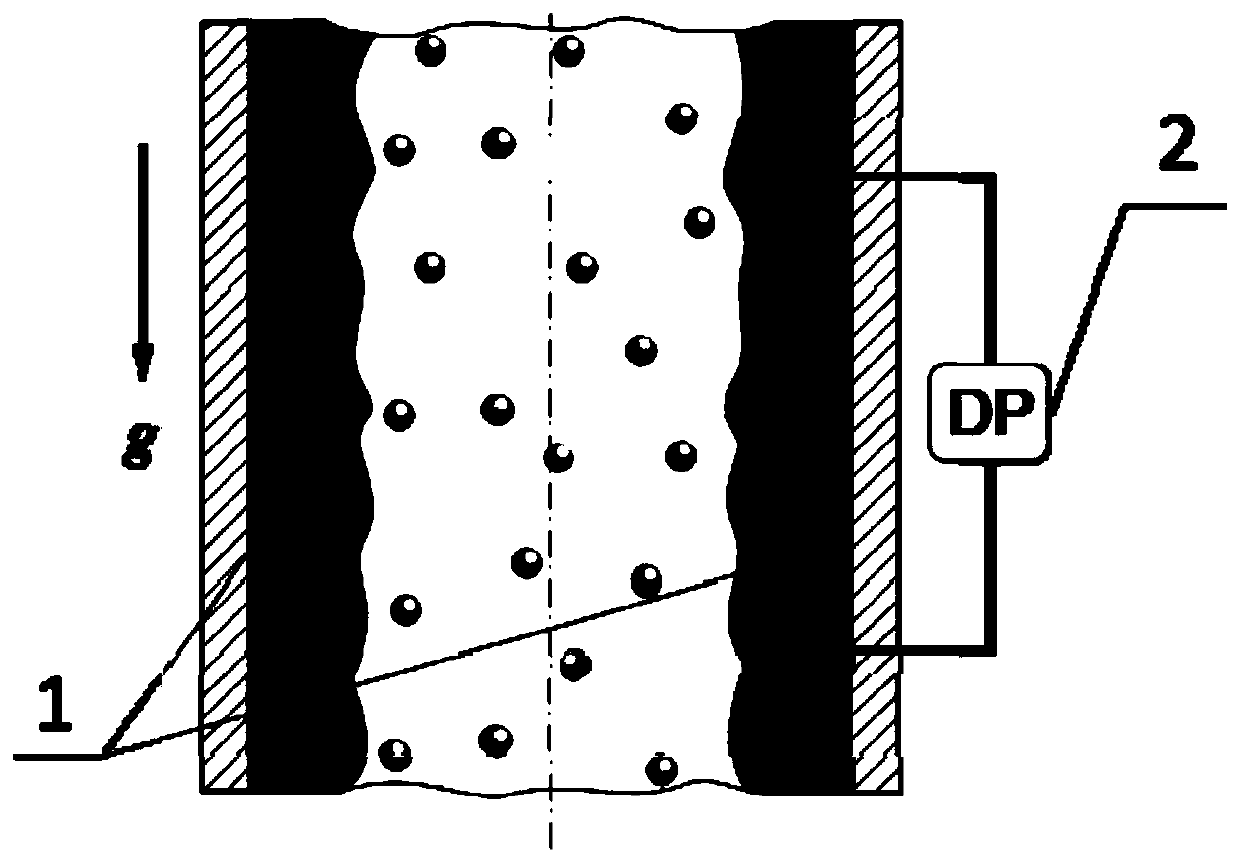

[0049] 1) Measure the pressure drop gradient of the gas-liquid two-phase annular flow in the vertical pipe through the differential pressure transmitter 2 Then measure the shear stress τ between the gas-liquid two-phase annular flow liquid film and the pipe wall in the vertical pipe through the shear stress sensor 1 w ;

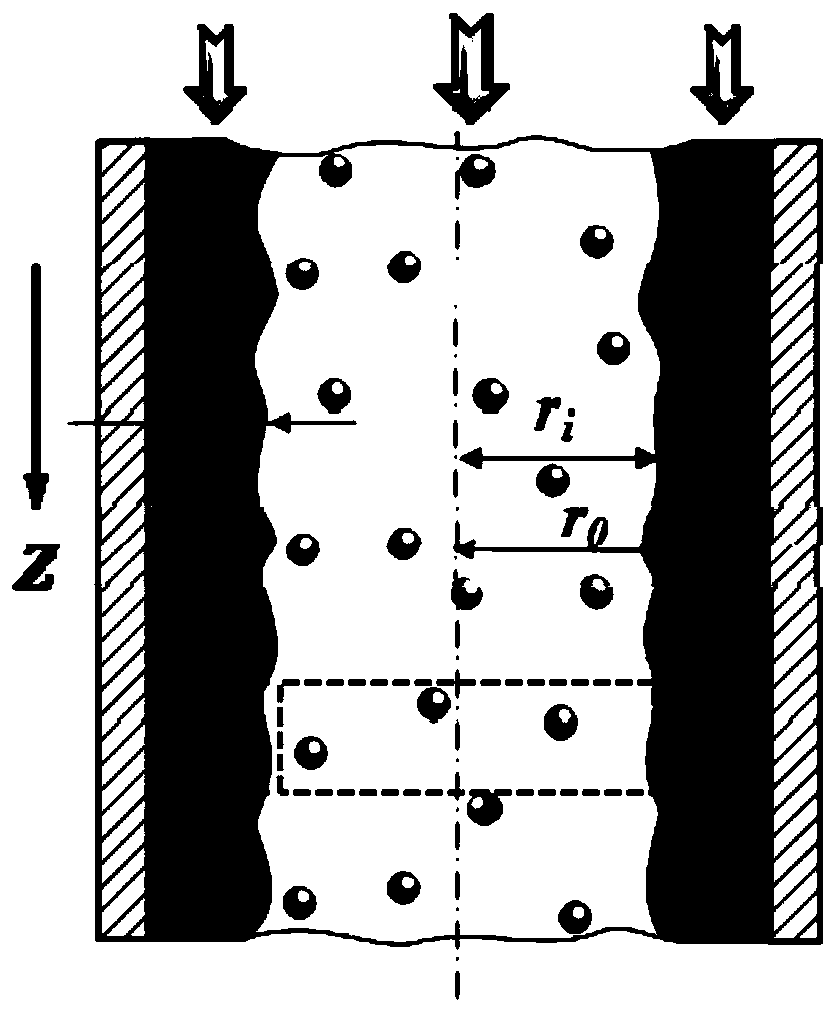

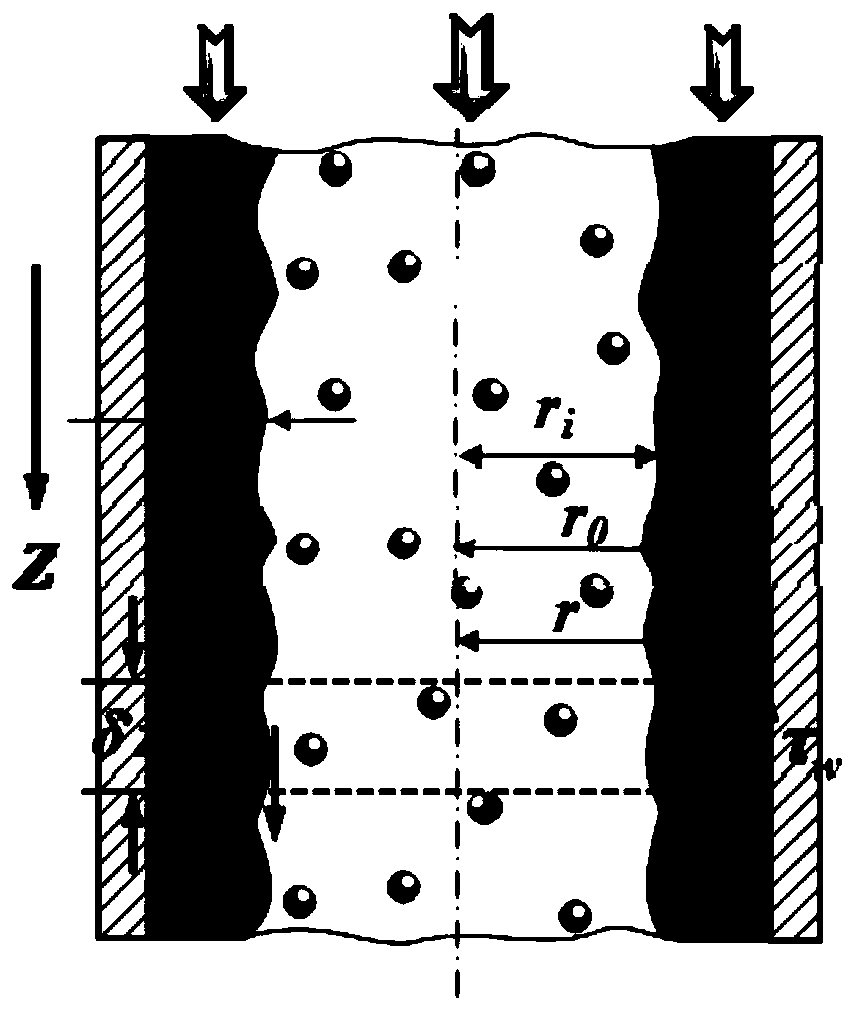

[0050] 2) Select the columnar control body to analyze the force of the gas core to obtain the momentum equation of the gas core, and select the annular control body to analyze the force of the liquid film to obtain the momentum equation of the liquid film;

[0051] 3) According to the gas core momentum equation and the liquid film momen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com