Handheld infrared flaw detector and detection method thereof

An infrared flaw detection, hand-held technology, applied in the field of defect detection, can solve the problems of large volume, inconvenience to carry, and the overall weight of the equipment, and achieve the effects of easy portability, weight reduction, and convenience for calling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0045] Embodiment 3 of the present invention is a handheld infrared flaw detector. On the basis of Embodiment 2, asbestos, thermal nylon, PEEK, etc. can be selected as the heat insulating material 4 .

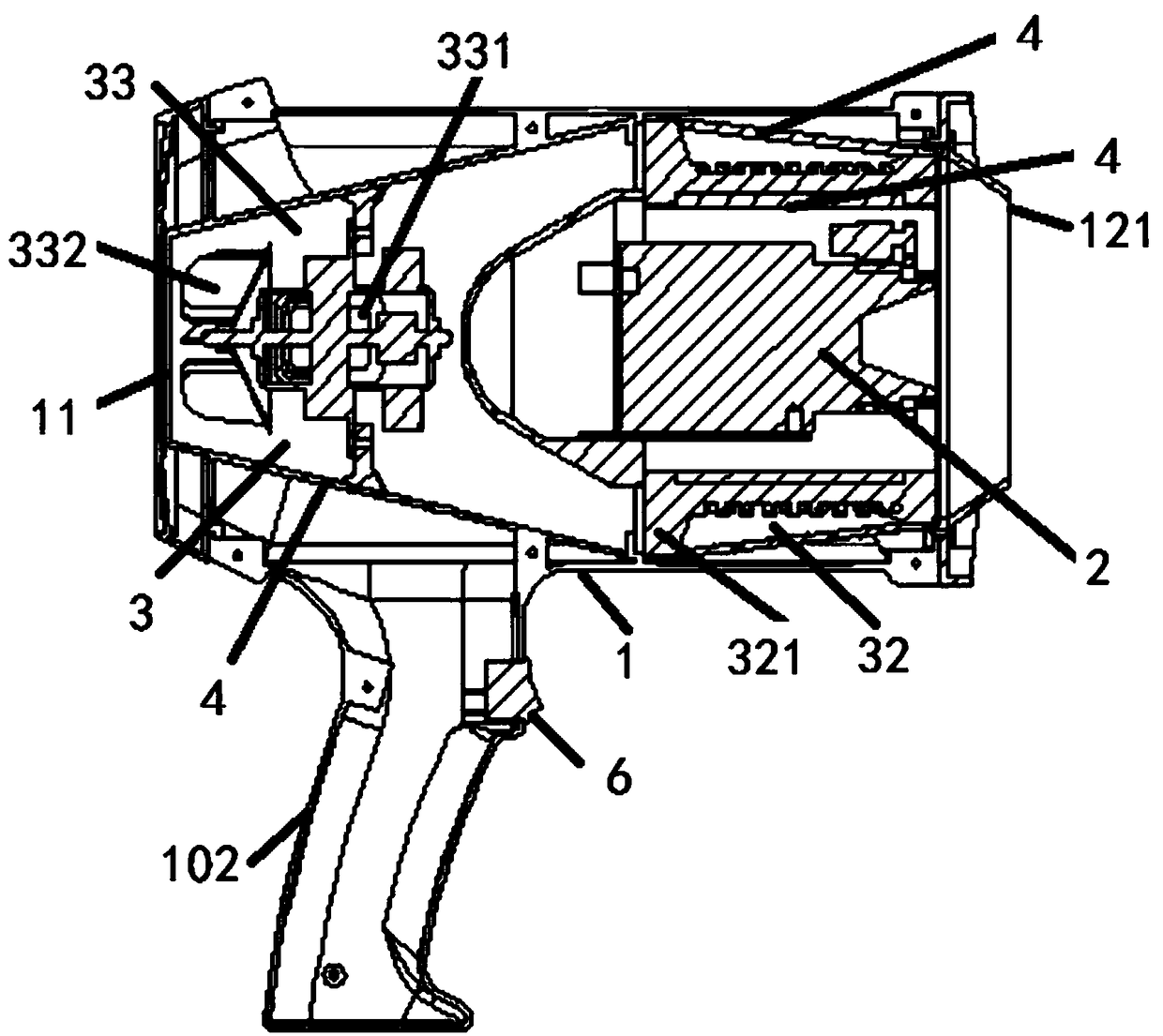

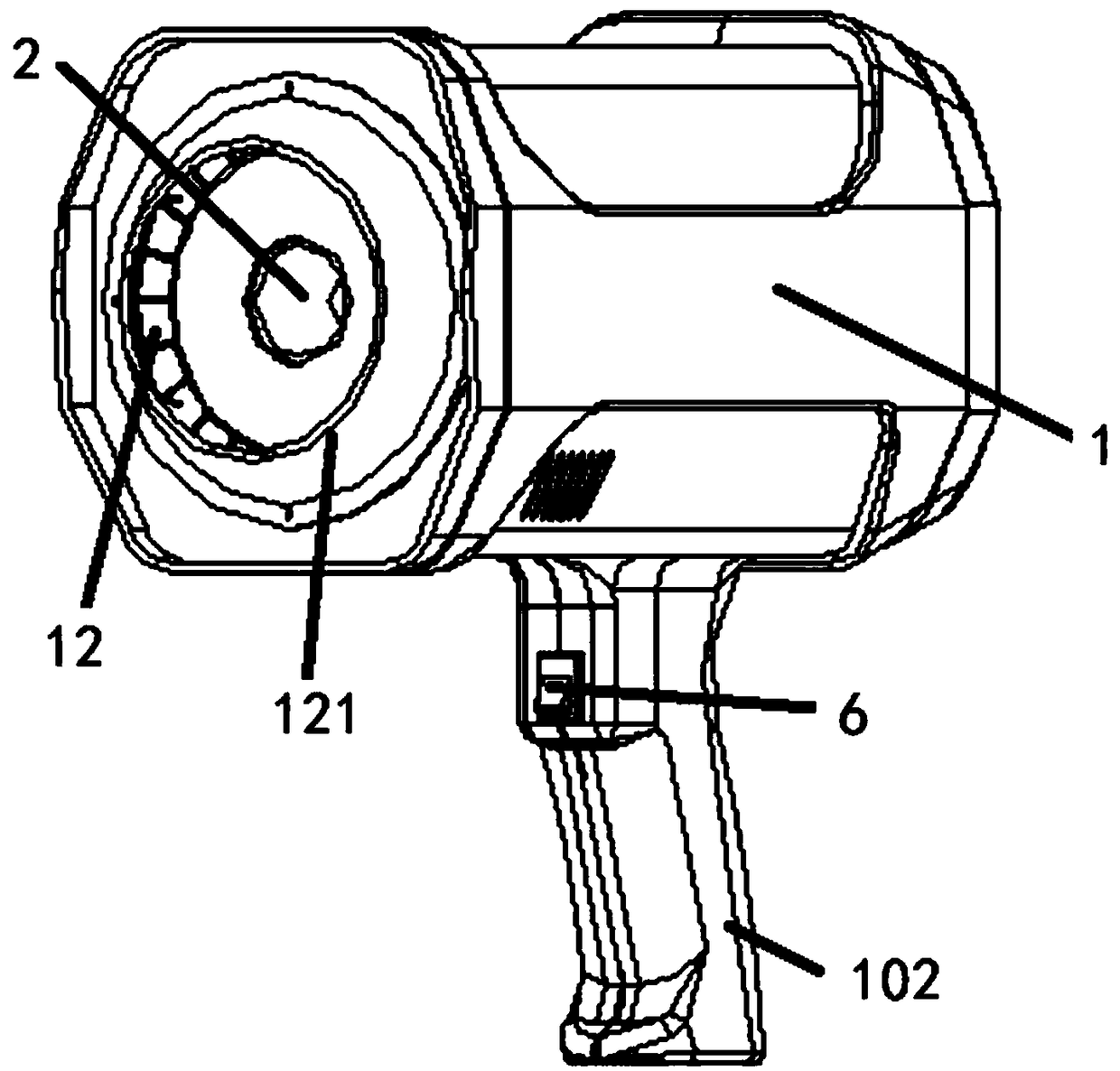

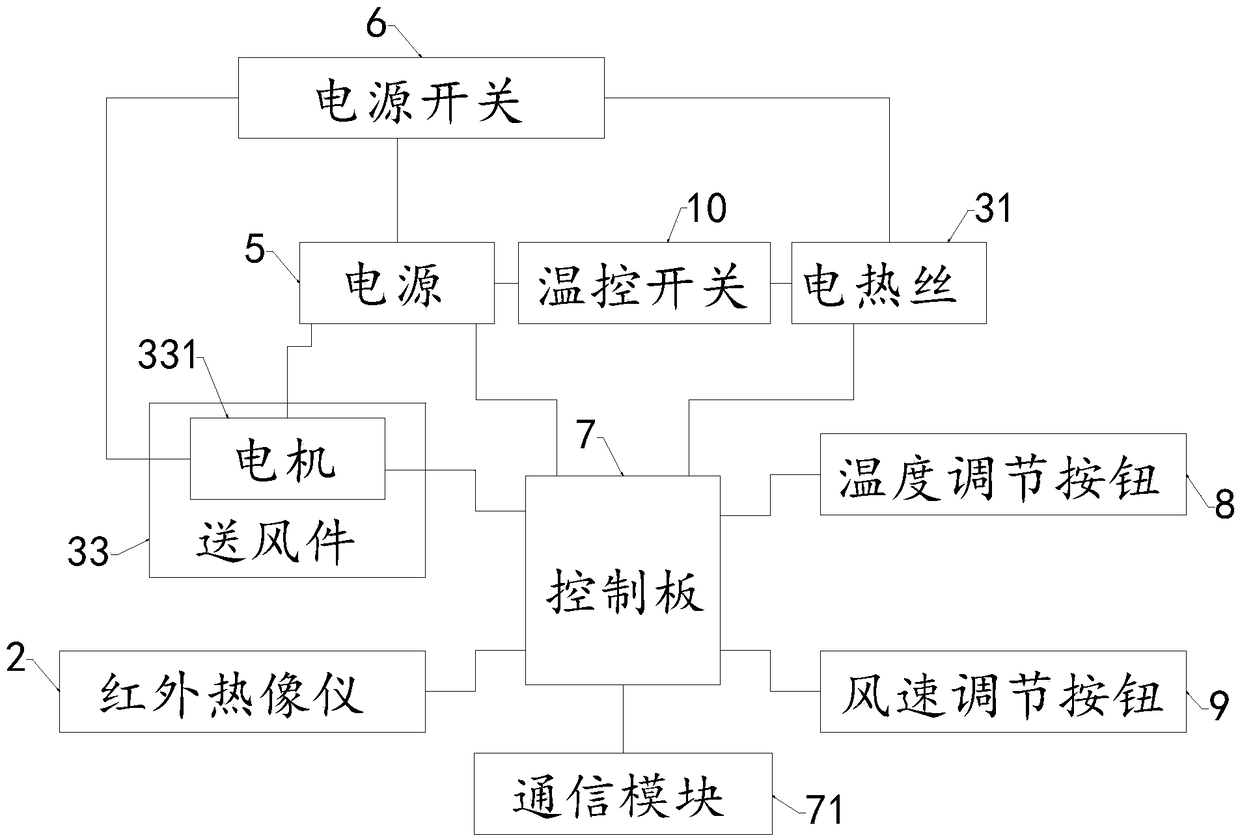

[0046] like figure 1 As shown, Embodiment 4 of the present invention is a handheld infrared flaw detector. On the basis of Embodiment 1, the air supply member 33 is a fan, and the fan includes a motor 331 and a fan blade 332. The motor 331 is fixed in the casing 1, and the fan blade 332 is fixed on the output shaft of the motor 331 .

[0047] like figure 1 As shown, Embodiment 5 of the present invention is a handheld infrared flaw detector. On the basis of Embodiment 1, the heating wire mounting frame 32 includes a plurality of mounting plates 321 fixed in the housing 1, and the plurality of mounting plates 321 are circumferential Distributed on the outer circumference of the infrared thermal imager 2 ; the heating wires 31 are wound on a plurality of mounting plates 321 . T...

Embodiment 6

[0048]Embodiment 6 of the present invention is a handheld infrared flaw detector. On the basis of Embodiment 1, the heating wire mounting frame 32 includes a plurality of mounting plates 321 fixed in the housing 1, and the plurality of mounting plates 321 are located in the infrared thermal imager. 2 above or below; the heating wire 31 is wound on a plurality of mounting plates 321 . The number of the mounting plates 321 can be selected as three, four, five and so on. The plurality of mounting plates 321 are preferably evenly distributed in a circumferential shape. The structure of the heating wire mounting frame 32 is made symmetrical, and the force of each mounting plate 321 is balanced.

Embodiment 7

[0049] Embodiment 7 of the present invention is a handheld infrared flaw detector. On the basis of Embodiment 1, the heating wire mounting frame 32 includes a plurality of mounting plates 321 fixed in the housing 1, and the plurality of mounting plates 321 are located in the infrared thermal imager. 2. The side close to or away from the air outlet 12; the heating wire 31 is wound on a plurality of mounting plates 321. The number of the mounting plates 321 can be selected as three, four, five and so on. The plurality of mounting plates 321 are preferably evenly distributed in a circumferential shape. The structure of the heating wire mounting frame 32 is made symmetrical, and the force of each mounting plate 321 is balanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com