Polyethylene glycol-modified recombinant glutathione peroxidase GPx1 mutant, preparation and antioxidant application methods thereof

A technology of glutathione peroxide and polyethylene glycol, applied in biochemical equipment and methods, oxidoreductase, medical preparations of non-active ingredients, etc., can solve the problem of reduced enzyme activity, short half-life, and stability Low-level problems, to achieve the effect of eliminating the antibody reaction of enzyme protein antigen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

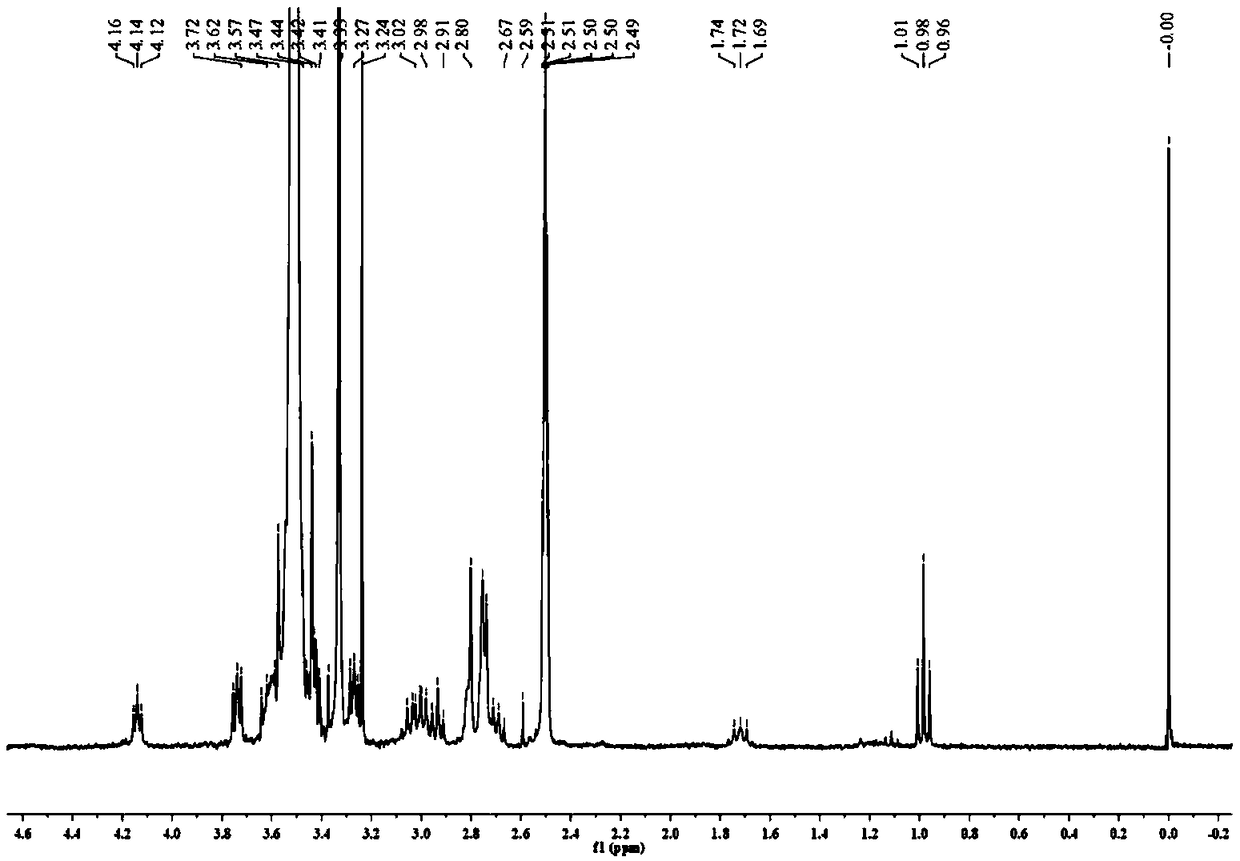

[0062] Example 1 Synthesis of activated linear monomethoxy polyethylene glycol succinimide butyrate.

[0063] 1. Obtained by the following methods:

[0064] (1) Weigh 2.0 g of monomethoxy polyethylene glycol (mPEG) with a molecular weight of 5000, add 4 mL of N,N-dimethylformamide to the flask, and fully dissolve it.

[0065] (2) Add 0.12g of succinic anhydride, mix well, and seal.

[0066] (3) The mixture was reacted at 100°C for 3 hours.

[0067] (4) After cooling the above reaction solution to room temperature, add 0.466g of N-hydroxysuccinimide, 0.825g of 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride, and heat to It dissolves.

[0068] (5) React overnight at 30°C for 12 hours, then cool to room temperature.

[0069] (6) Add 40 mL of ether dropwise to the cooled reaction solution at 4°C, filter the resulting precipitate, and dry in vacuum. The dried product was dissolved in dichloromethane and then precipitated with ether. Repeat this process 4 times.

[0070] (7) The res...

Example Embodiment

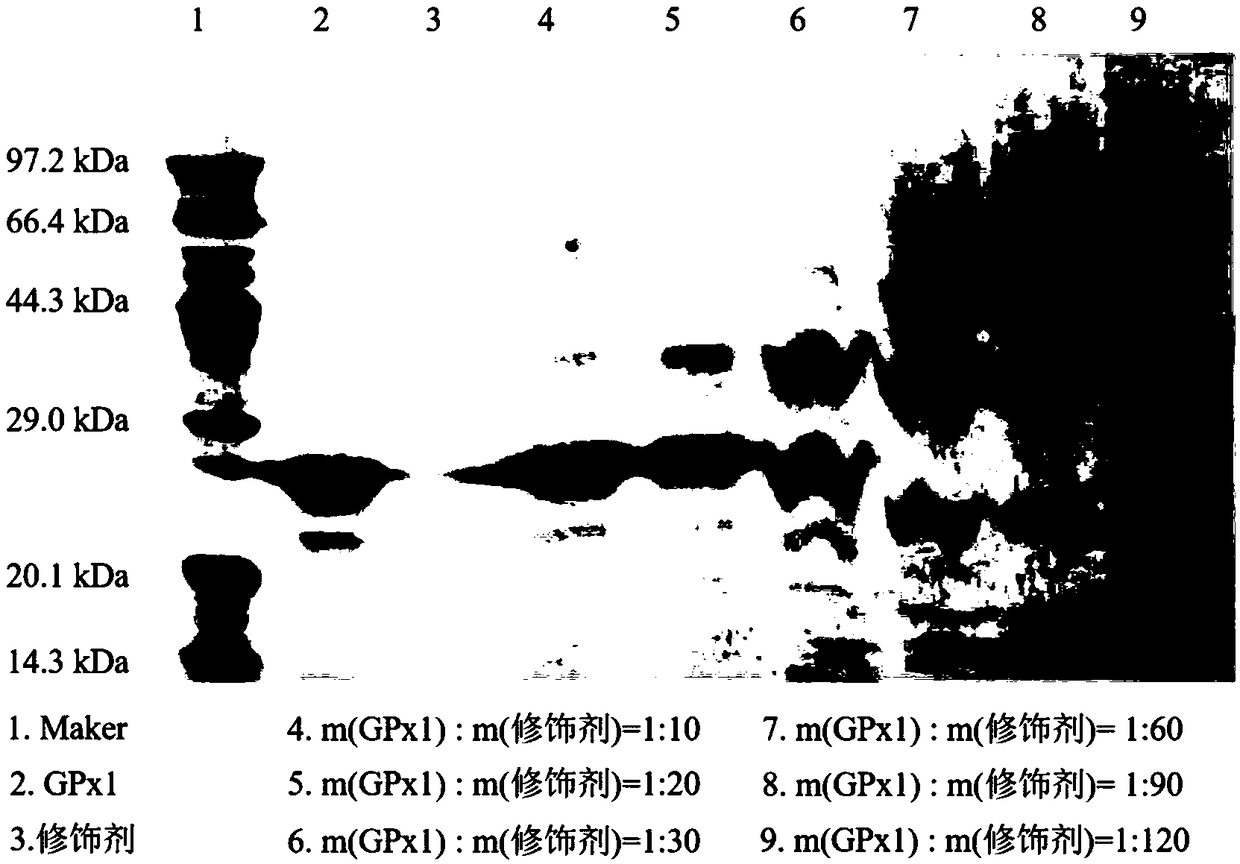

[0078] Example 2

[0079] Performance evaluation of modified products of mPEGylated recombinant glutathione peroxidase GPx1 mutant:

[0080] (1) When the mass ratio of recombinant glutathione peroxidase GPx1 mutant to linear monomethoxy polyethylene glycol succinimidyl butyrate is 1:60, the thermal stability of the obtained enzyme is improved.

[0081] The reaction system is 500μL, which contains 50mmol / L pH 7.4 PBS, 1mmol / L EDTA, 1mmol / LGSH, 0.25mmol / L NADPH, 1U glutathione reductase and 20-50nM protein sample. The reaction mixture is pre-heated at 19~55℃ for 5min, and then the final concentration is 0.5mmol / L H 2 O 2 Start the reaction. Monitor the change of NADPH absorbance value at 340nm by UV spectrophotometer. Enzyme activity is defined as the amount of enzyme required for the protein to oxidize 1 μmol NADPH per minute at 37°C, and it is expressed as 100% enzyme activity. Such as Figure 5 As shown, at 55°C, the recombinant glutathione peroxidase GPx1 mutant maintained a rel...

Example Embodiment

[0083] Example 3

[0084] The modified product of mPEGylated recombinant glutathione peroxidase GPx1 mutant (mPEG-GPx1) freeze-dried protective agent screening:

[0085] In a 4 degree chromatography refrigerator, GPx1 and mPEG-GPx1 were dialyzed in a solution (200 mL) containing 10% mannitol and 5% glycine (W / V) freeze-dried protective agent for 4 hours, and the dialysate was changed 4 times in the middle. After the dialysis is completed, pre-freeze at -20°C for 12 hours and freeze-dry in a Zirbus Voco 5 freeze dryer; GPx1 and mPEG-GPx1 samples without lyophilization protection agent are pre-freeze at -20°C for 12 hours, It was freeze-dried in a Zirbus Voco 5 freeze-drying machine; according to the enzyme activity determination method in Example 2, the enzyme activity at 37°C was measured. The enzyme activity of the sample before freeze-drying is calculated as 100%.

[0086] After lyophilizing GPx1 and mPEG-GPx1 directly, the enzyme activities maintained 75.36% and 82.42% respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com