Modified glutathione peroxidase and preparation method thereof

A technology of glutathione peroxidase and glutathione peroxidase, which is applied in the direction of fixing on/in the organic carrier, can solve the problems of easily oxidized enzymes, limited practicability, and short half-life, etc. Achieve the effect of modifying the enzyme with high activity and eliminating the antibody reaction of the enzyme protein antigen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

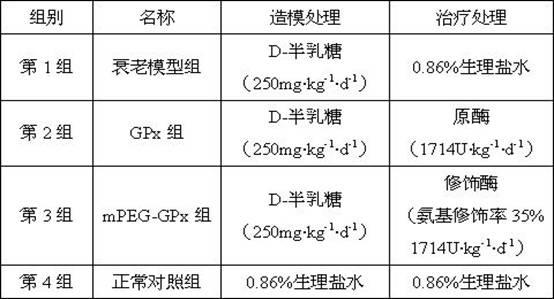

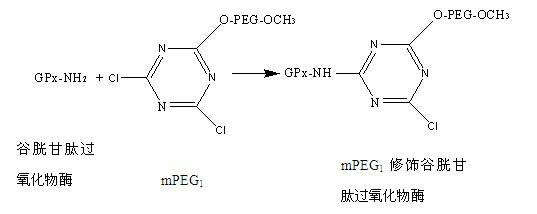

[0024] 1. Activation of mPEG 1 The acquisition of:

[0025] Take 5.5g of secondary recrystallized cyanuric chloride (recrystallized twice with anhydrous benzene first) and dissolve it in 400mL of anhydrous benzene containing 10g of anhydrous sodium carbonate, add 50g of mPEG-5000, stir overnight at room temperature, filter , take about 400mL of filtrate and stir and slowly add 600mL of diethyl ether, continue to stir for 20min after the white product precipitates, filter with suction, and dissolve the precipitate with 400mL of anhydrous benzene. up to the absorption peak. Place the activated mPEG in a vacuum desiccator to dry it up to obtain a white powder, that is, to obtain activated mPEG 1 .

[0026] 2. Acquisition of pig lung-derived glutathione peroxidase: take 500g of healthy pig lung, add 1000mL pre-cooled 20mmol / L pH7.2 phosphate buffer (containing 2mmol / L mercaptoethanol, 1mmol / L EDTA), Homogenate, centrifuge at 12 000r / min at 4°C for 15min, the enzyme liquid is d...

Embodiment 2

[0030] 1. Activation of mPEG 1 Acquisition: as in Example 1

[0031] 2. Acquisition of pig lung-derived glutathione peroxidase: take 500g of healthy pig lung, add 1000mL pre-cooled 20mmol / L pH7.2 phosphate buffer (containing 2mmol / L mercaptoethanol, 1mmol / L EDTA), Homogenate, centrifuge at 12 000r / min at 4°C for 15min, the enzyme liquid is divided into three layers, the upper layer is the fat layer, and the lower layer is the precipitate, remove the precipitate and fat layer to obtain the crude enzyme liquid; then precipitate with 30-50% ethanol, DEAE- Cellulose (DE 52 ), DEAE-Sephadex A50, and the second DE 52 treatment, and finally treated with Sephadex G-150, the pure enzyme with reasonable yield and high specific activity can be obtained.

[0032] 3. Modification of pig lung-derived glutathione peroxidase:

[0033] The reaction temperature is 36°C, pH 7.0, and the reactant ratio is 1 mg of enzyme and 0.04 g of modifying agent for reaction. After 30 minutes, GSH is adde...

Embodiment 3

[0035] 1. Activation of mPEG 1 Acquisition: as in Example 1

[0036] 2. Acquisition of pig lung-derived glutathione peroxidase: take 500g of healthy pig lung, add 1000mL pre-cooled 20mmol / L pH7.2 phosphate buffer (containing 2mmol / L mercaptoethanol, 1mmol / L EDTA), Homogenate, centrifuge at 12 000r / min at 4°C for 15min, the enzyme liquid is divided into three layers, the upper layer is the fat layer, and the lower layer is the precipitate, remove the precipitate and fat layer to obtain the crude enzyme liquid; then precipitate with 30-50% ethanol, DEAE- Cellulose (DE 52 ), DEAE-Sephadex A50, and the second DE 52 treatment, and finally treated with Sephadex G-150, the pure enzyme with reasonable yield and high specific activity can be obtained.

[0037] 3. Modification of porcine lung-derived glutathione peroxidase:

[0038] The reaction temperature is 5°C, the pH is 10.0, and the reactant ratio is 1 mg of enzyme and 0.02 g of modifier for the reaction. After 60 minutes, GSH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com