A kind of structure design method of expanding and extruding friction anchor rod and cable

A technology for structural design and bolting, which is applied in the installation of bolting, infrastructure engineering, mining equipment, etc., can solve the problems of waste of resources, high cost, and randomness of experimental results, and achieves high accuracy that meets engineering needs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

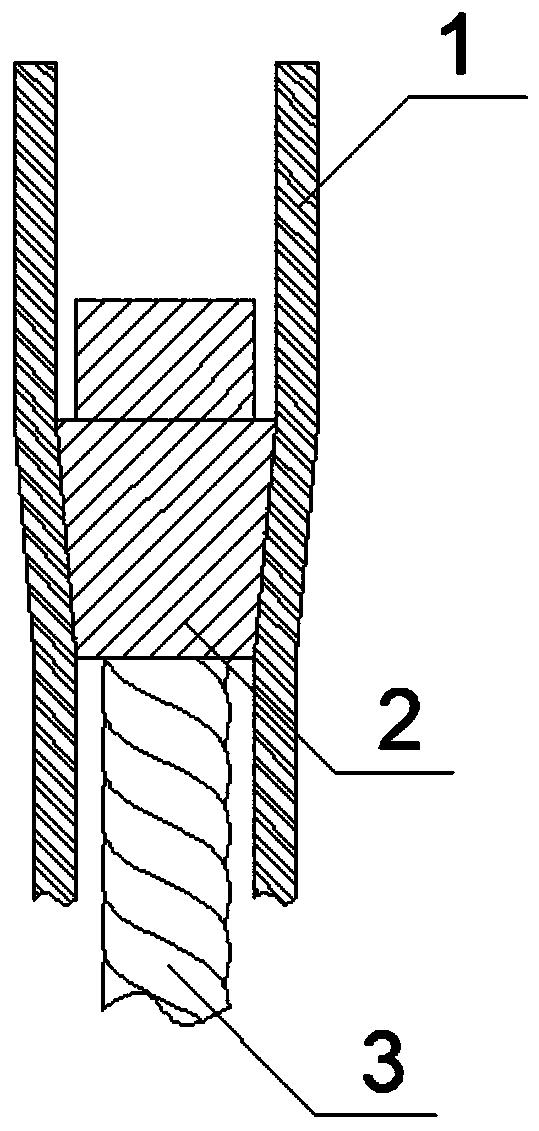

[0039] According to the accompanying drawings, the present invention will be described in detail below. The flow chart of a method for designing a diameter-expanding extrusion friction anchor rod and anchor cable structure of the present invention is as follows: figure 1 As shown, the design of the anchor cable is taken as an example here for illustration, and this invention is also applicable to the design of the anchor rod:

[0040] Step 1, given the design constant resistance of 300000N required by the actual project of the anchor cable, the cable body 3 is selected as a steel strand with a tensile strength of 1860MPa, and the size of the cable body 3 is determined according to the formula (1):

[0041]

[0042] Among them, σ gs is the yield strength of the cable body 3, which is 88% to 95% of its tensile strength, S g is the nominal cross-sectional area of the cable body 3, and the yield strength of the cable body 3 in this embodiment is taken as 90% of its tensile s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap