Cable pay-off device

A technology of pay-off device and branching device, which is applied in conductor/cable supply device, cable/conductor manufacturing, circuit, etc. It can solve the problems of lowering the quality of cables and contamination of wires with sundries, etc., so as to improve performance and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Embodiments of the present invention include, but are not limited to, the following examples.

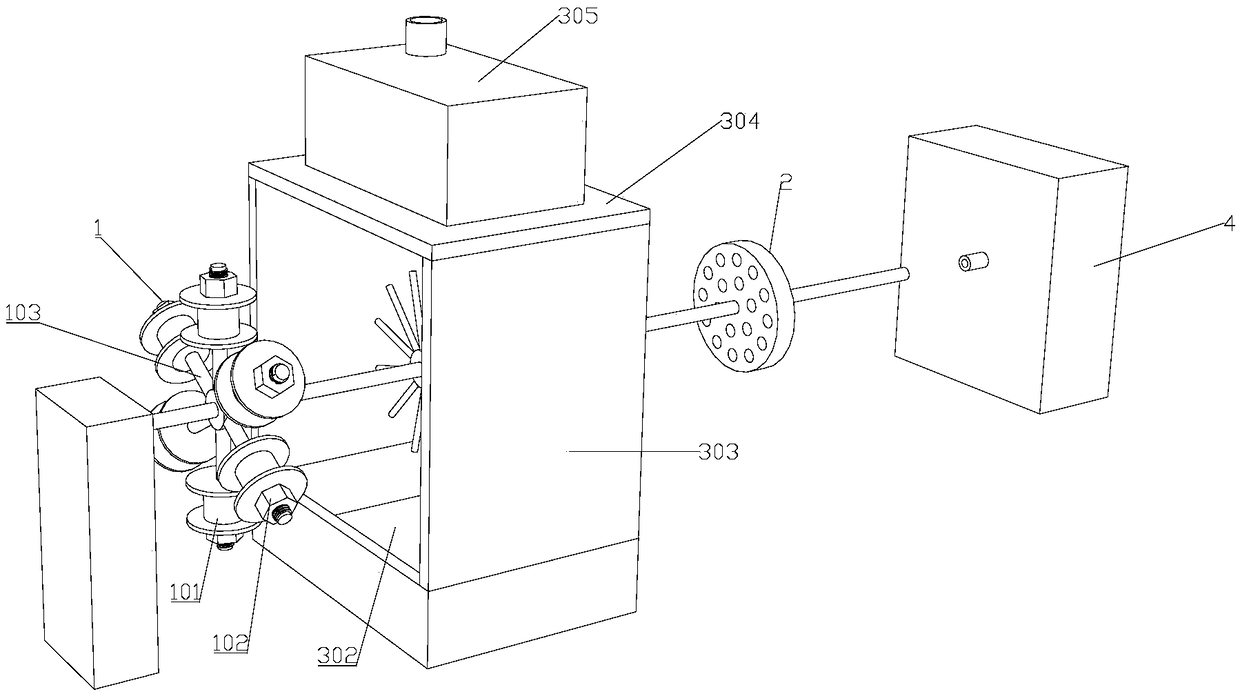

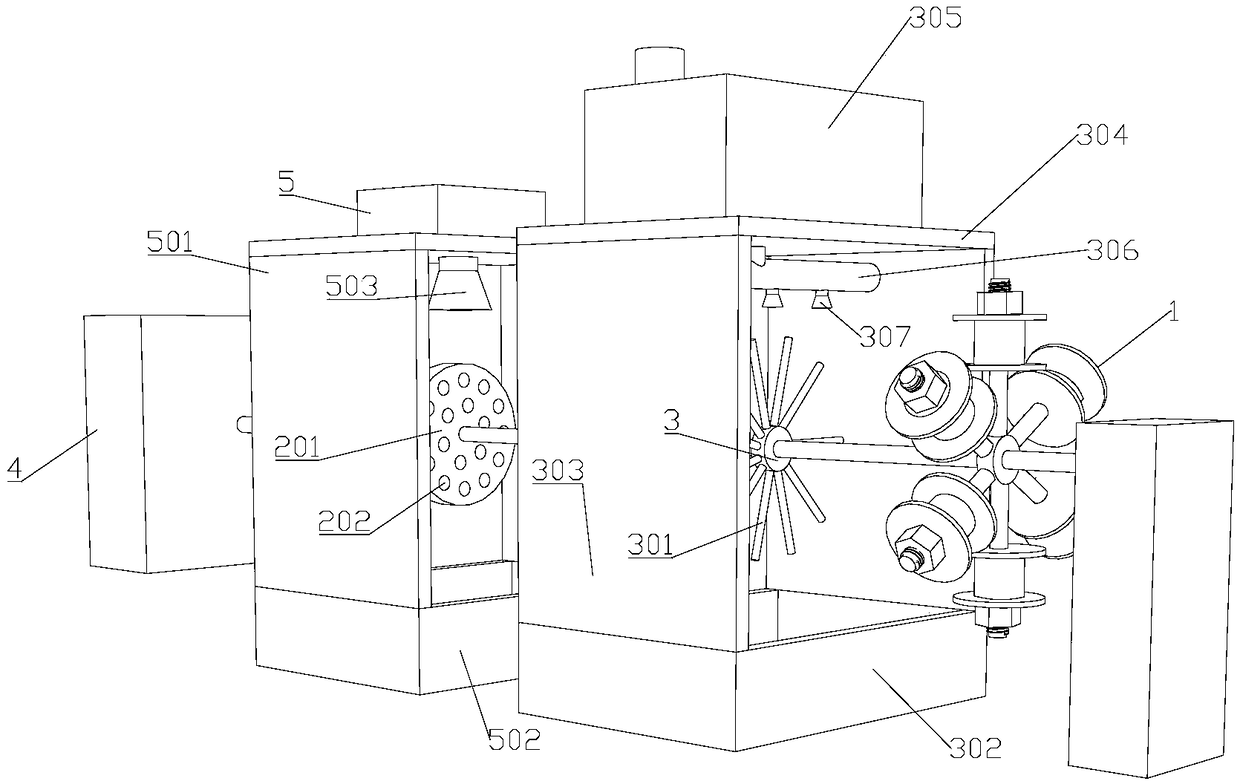

[0015] like figure 1 , figure 2 As shown, a cable pay-off device 1 is used to feed wires into a stranding machine 4, including a pay-off device 1, a wire splitting device 2, and a wire stranding machine 4 arranged in sequence along the wire incoming direction, wherein the pay-off device 1 One side is provided with a supporting platform, and the supporting platform is fixedly connected with a bearing shaft. The wire releasing device 1, the wire dividing device 2 and the wire twisting machine 4 are all fixed on the bearing shaft, and are supported by the bearing shaft; the wire releasing device 1 and the wire dividing device 2 is provided with a partition plate 3, and the partition plate 3 is evenly distributed along the circumferential dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com