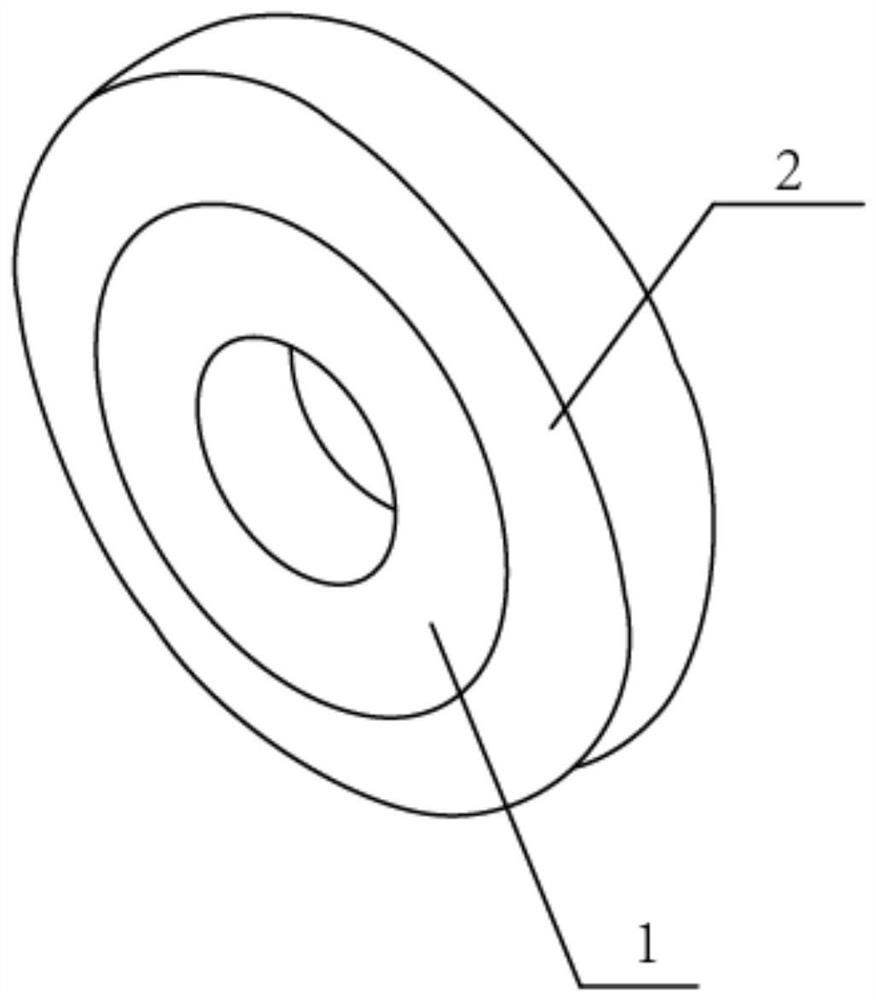

Cold sawing wheel with single bevel structure and preparation method thereof

A grinding wheel and cold sawing technology, which is applied in the field of cold sawing grinding wheel with a single bevel structure and its preparation, can solve the problems that the grinding wheel cannot achieve single-sided force, damage the operator, and wear out the workpiece, etc., and achieve the improvement of adhesion, The effect of saving enterprise cost and reducing copper plating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

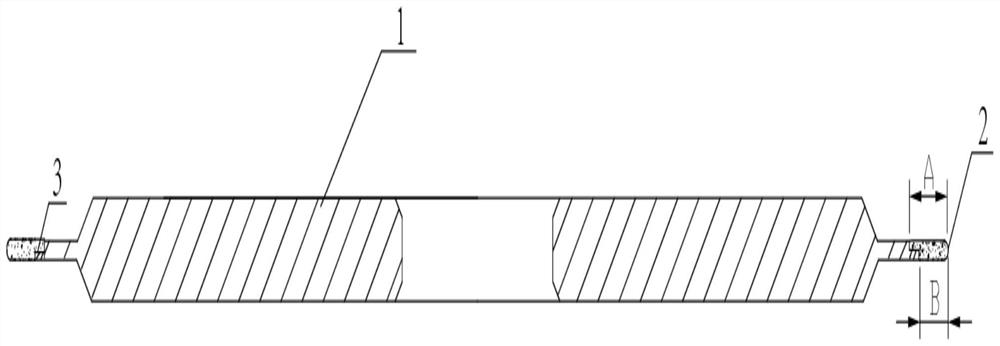

[0057] Example 1 Making a 14A1, 200×10×55×10×1.3 cold saw grinding wheel

[0058] 1. Turning the substrate: According to the requirements of the drawings, the 45# steel substrate is processed to obtain a substrate with a horizontal Z-shaped structure; in the horizontal Z-shaped structure, the lower vertical surface is provided with a knurled structure, and the upper vertical surface and the horizontal surface are respectively There are a plurality of grooves; the thickness C of the upper vertical surface is 0.8mm, and the thickness D of the lower vertical surface is 0.7mm;

[0059] The length of the horizontal Z-shaped structure is 3mm. In the knurled structure, the knurling depth is 0.3mm and the tooth spacing is 0.3mm; in the upper vertical plane, the spacing between each groove is 0.2mm, and the depth of each groove is 0.4mm, the width of each slot is 0.3mm; in the horizontal plane, the spacing between each slot is 0.2mm, the depth of each slot is 0.2mm, and the width of ea...

Embodiment 2

[0066] Example 2 Making a 14A1, 150×20×55×10×2 cold saw grinding wheel

[0067] 1. Turning the substrate: According to the requirements of the drawings, the 45# steel substrate is processed to obtain a substrate with a horizontal Z-shaped structure; in the horizontal Z-shaped structure, the lower vertical surface is provided with a knurled structure, and the upper vertical surface and the horizontal surface are respectively There are multiple grooves; the thickness of the upper vertical surface is 0.85mm, and the thickness of the lower vertical surface is 0.65mm;

[0068] The length of the horizontal Z-shaped structure is 3mm. In the knurled structure, the knurling depth is 0.3mm and the tooth spacing is 0.3mm; in the upper vertical plane, the spacing between each groove is 0.2mm, and the depth of each groove is 0.4mm, the width of each slot is 0.3mm; in the horizontal plane, the spacing between each slot is 0.2mm, the depth of each slot is 0.2mm, and the width of each slot is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com