Improved positioning datum plate on woodworking sawing machine

A positioning datum, woodworking saw technology, applied in the direction of wood processing equipment, sawing components, manufacturing tools, etc., can solve the problems of inseparable from woodworking, difficult positioning and other problems, and achieve the effect of easy portability, easy fixation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

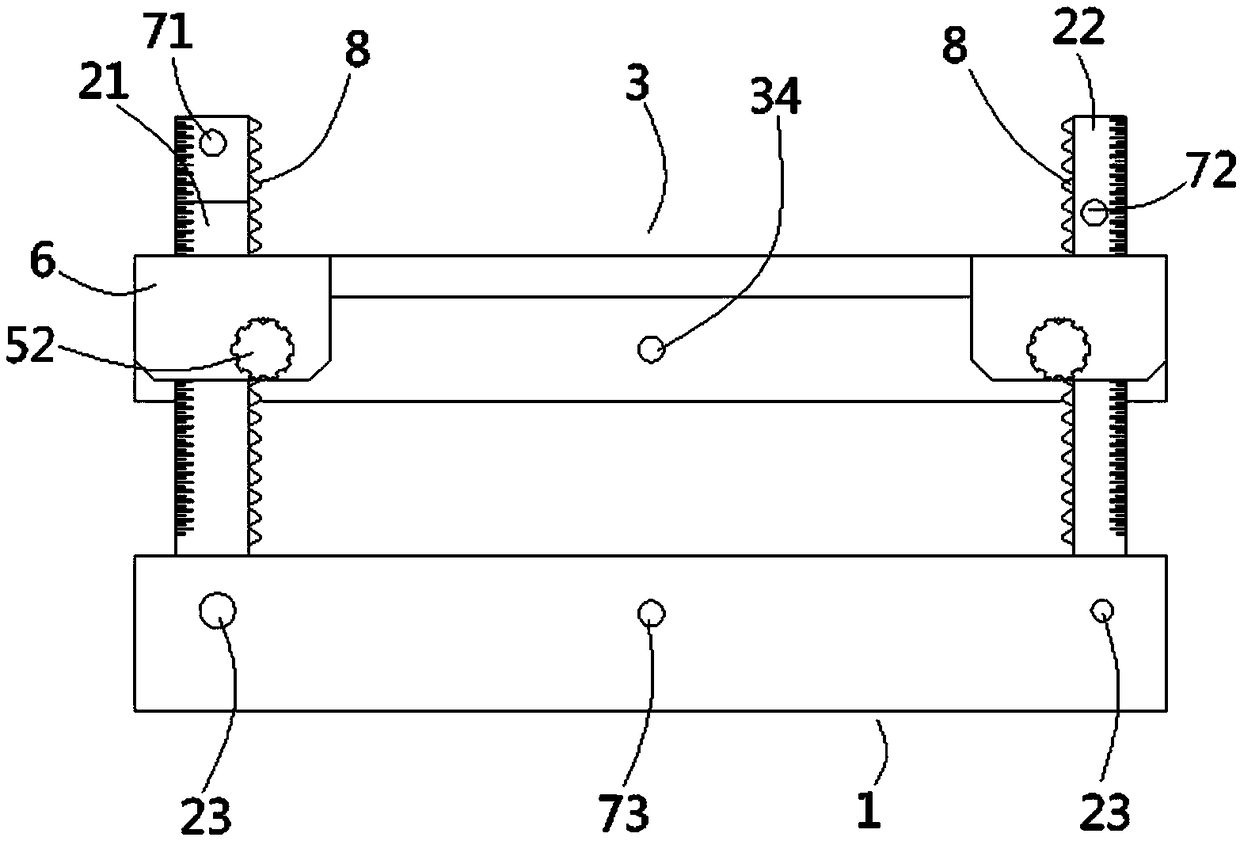

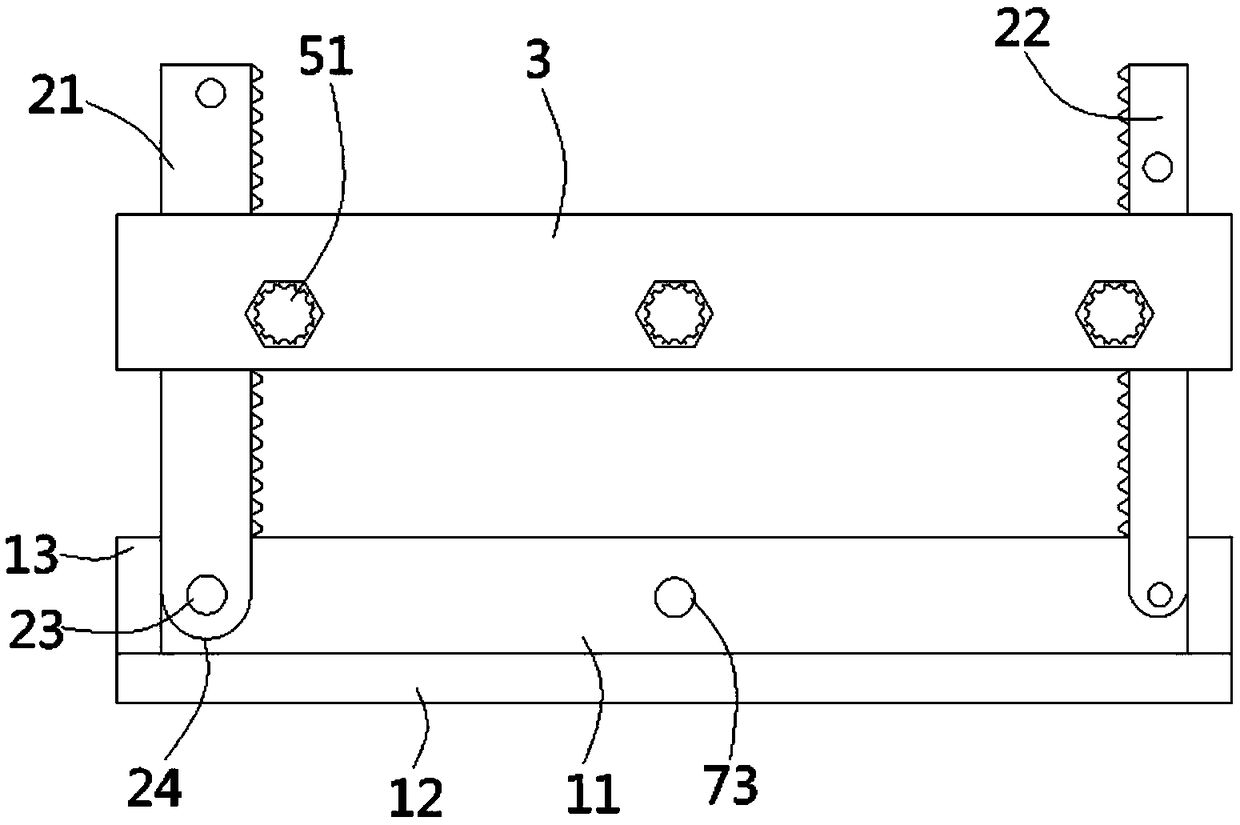

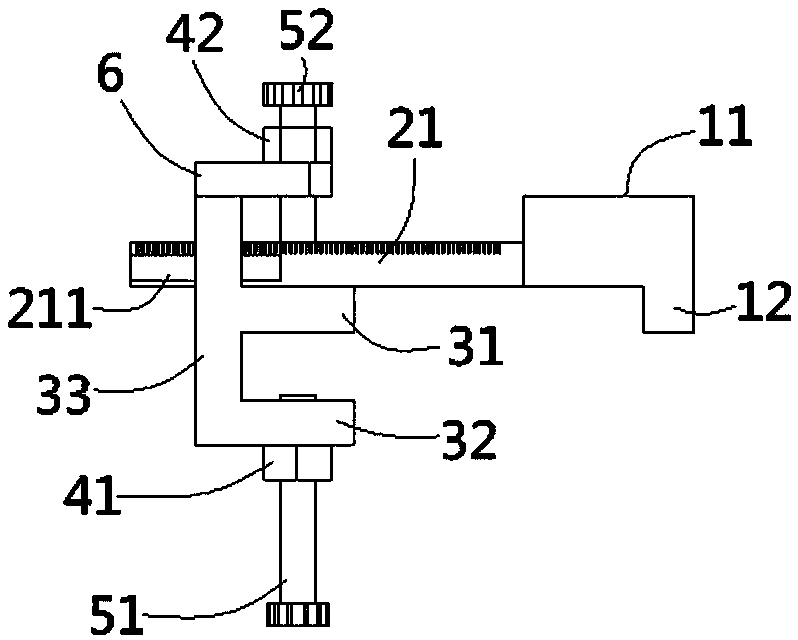

[0022] see Figure 1 to Figure 4 , an improved positioning reference plate on a woodworking sawing machine according to the present invention, comprising an L-shaped reference plate 1, the reference plate 1 is composed of a horizontal part 11 and a vertical part 12 formed on one side of the horizontal part 11 , the two sides of the horizontal part 11 of the reference plate 1 are respectively hinged with a first scale 21 and a second scale 22 through the hinge shaft 23, and the length of the first scale 21 and the second scale 22 is greater than the horizontal Half of the length of part 11, the thickness of the first scale 21 is greater than the thickness of the second sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com