Mixer and a method for operating same

A technology of mixers and injectors, applied in the direction of combustion methods, combustion chambers, combustion equipment, etc., can solve different problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

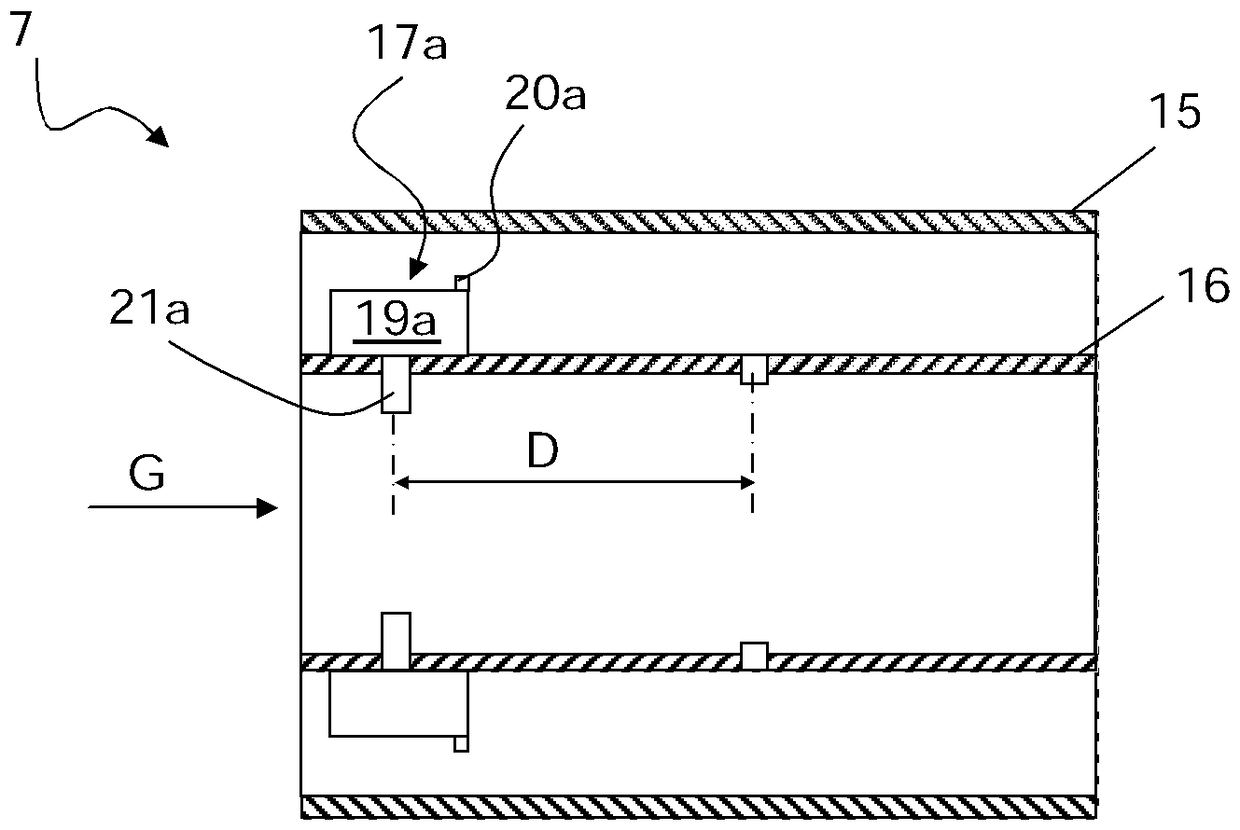

[0049] Referring to the figures, the mixer 7 is shown. The mixer 7 includes a housing 15 , a tube 16 within the housing 15 , a first injector 17a and a second injector 17b for injecting a fluid (eg, possibly cooled compressed air from a compressor) into the tube 16 ; The fluid is injected by the first injector 17a and the second injector 17b in a fluctuating mass flow.

[0050] As described below, the first injector 17a and the second injector 17b may be provided around the outer circumference of the tube 16 and may lead to the tube at one or more points.

[0051] The first injector 17a and the second injector 17b have a distance D such that the mass flow of fluid injected through the first injector 17a reaches the second injector in reverse phase to the mass flow of fluid injected through the second injector 17b 17b. For example, when the first injector 17a injects a large fluid mass flow, the large fluid mass flow travels axially through the tube 16 and reaches the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap