A tightening mechanism for inductive coil production

A technology of inductive coils and coils, which is applied in the direction of coil manufacturing, etc., can solve the problems of loose cloth hanging on the coils, poor leak-proof effect, waste of raw materials, etc., achieve good effect, easy control, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

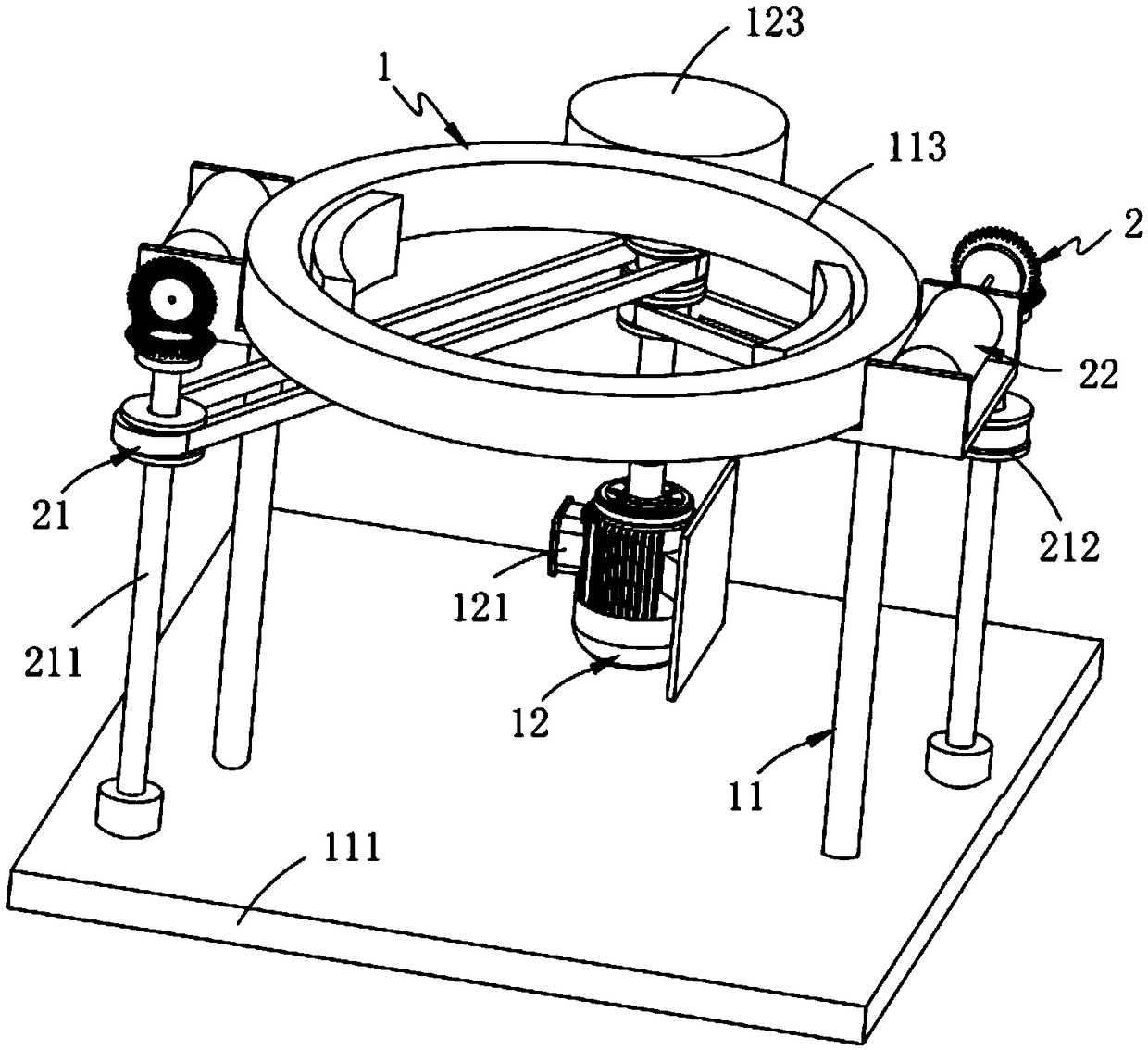

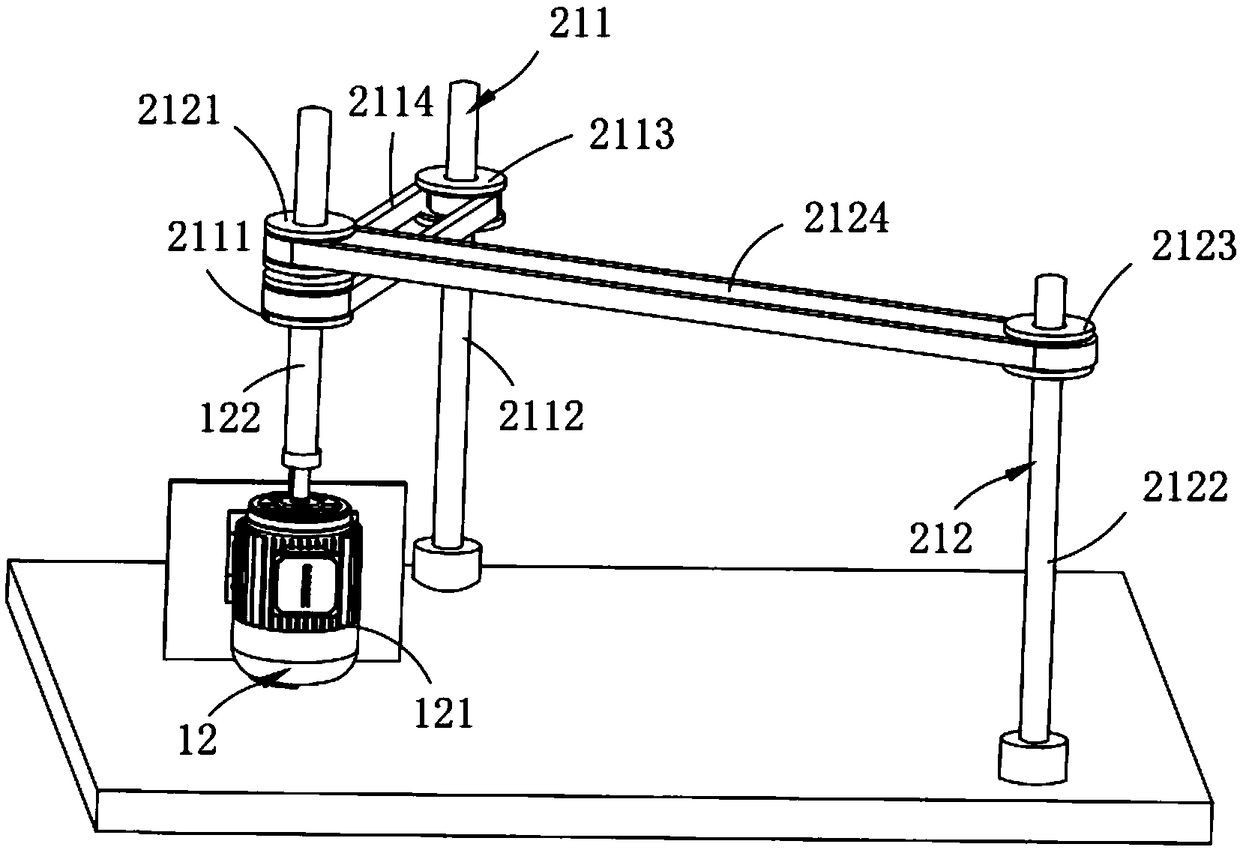

[0051] Such as figure 1 As shown, a tightening mechanism for inductive coil production includes:

[0052] A cloth wrapping assembly 1, the cloth wrapping assembly 1 comprising a support 11 and a driving member 12 arranged on the support 11 and used to drive the support 11 to rotate; and

[0053] The tightening assembly 2 includes a transmission member 21 which rotates synchronously with the driving member 12 and a delivery member 22 which is arranged on the support member 11 and cooperates with the transmission member 21 to drive.

[0054] In this embodiment, by setting the cloth wrapping assembly 1, the coil 113 is first automatically wound, and then the tightening assembly 2 is used to automatically tighten the cloth wound on the coil 113, instead of the manual winding of the transmission, to avoid manual winding. Uneven cloth winding force control, resulting in uneven cloth winding, sometimes loose and sometimes tight, on the one hand, it improves the effect of leak preven...

Embodiment 2

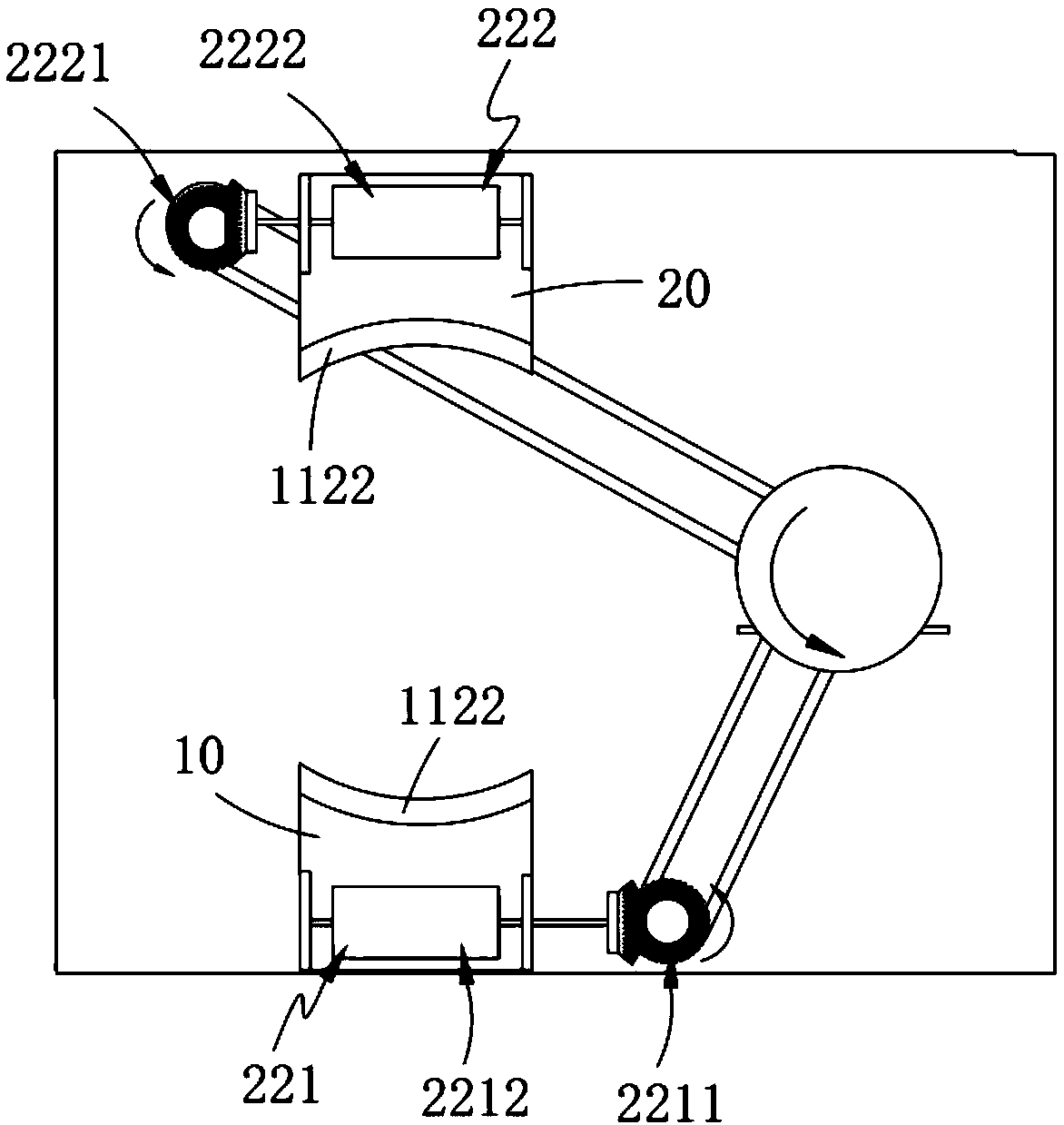

[0092] Such as Figure 5 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0093] further, such as Figure 5 As shown, the tightening shaft 2225 is provided with inclined threads.

[0094] In this embodiment, by setting an inclined screw thread on the tightening shaft 2225, it is the same as the winding of the cloth, that is, because the coil 113 is always rotating, and the cloth is held vertically, under the action of the eccentric force, the cloth will appear obliquely wound. As a result, when the direction of the thread matches the inclination and size of the cloth, a pushing force for tightening the cloth is increased to ensure the tightening scale, and the structure is simple and ing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com