Boundary Element Method for Calculation of Rolling Bearing Load and Pressure under Elastohydrodynamic Lubrication Condition

A boundary element method, rolling bearing technology, applied in design optimization/simulation, geometric CAD, sustainable transportation, etc., can solve the problems of too many divided units, not considering the influence of rolling bullet fluid lubrication, unsatisfactory calculation results, etc., to achieve calculation accuracy The effect of high, less unit division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

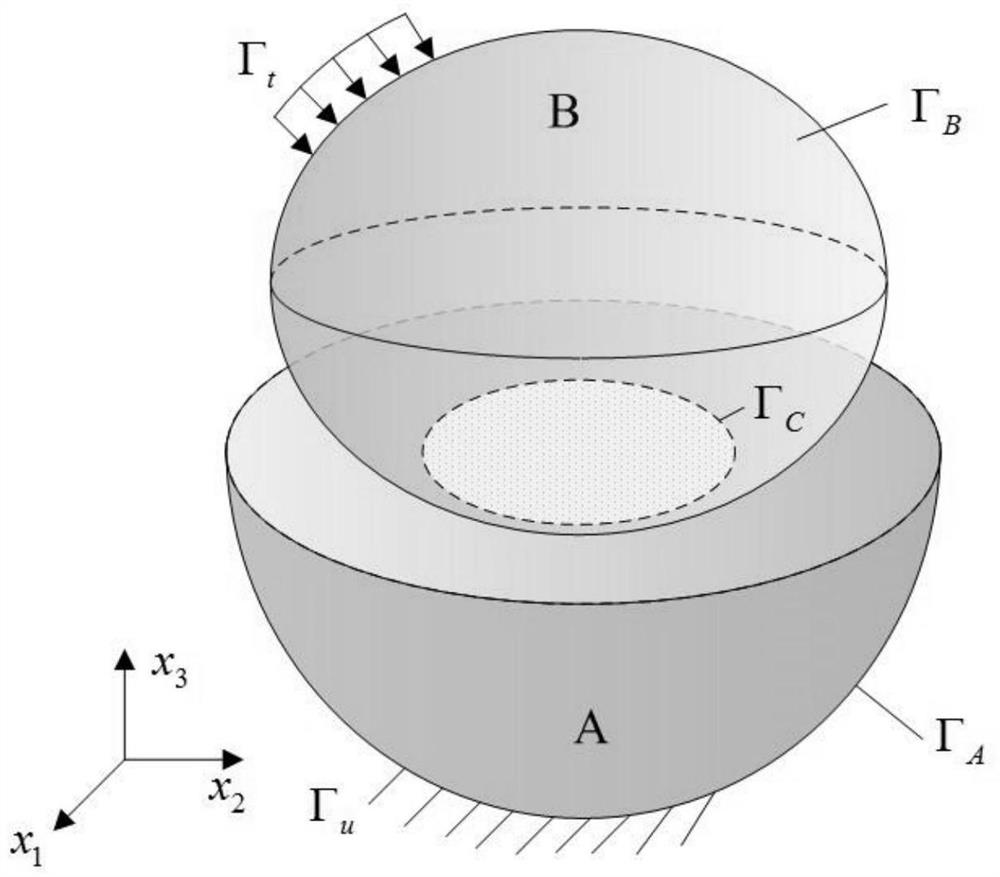

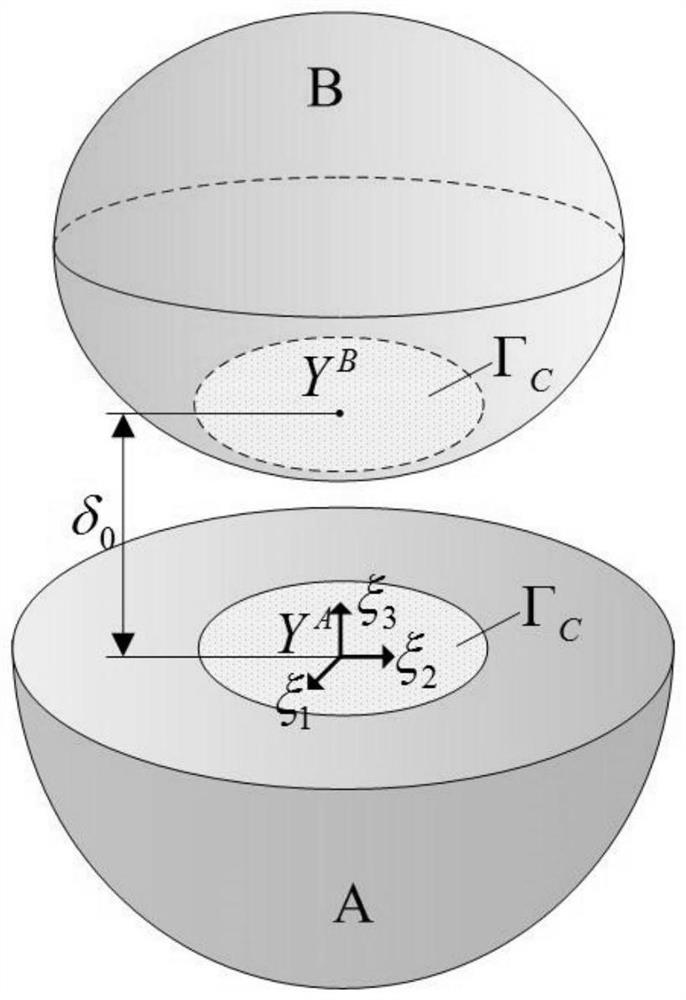

[0216] The present invention will be further described below in conjunction with accompanying drawing and embodiment: a kind of boundary element method of calculating rolling bearing load and pressure under the condition of elastohydrodynamic lubrication comprises the following steps,

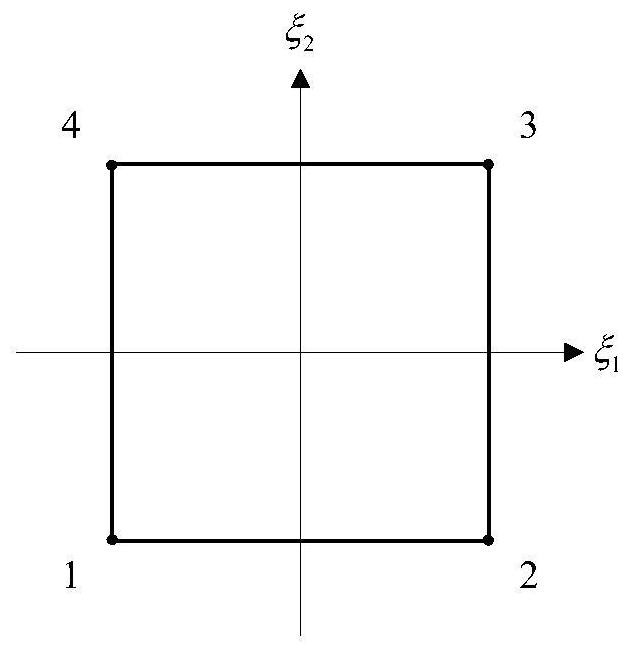

[0217] Step 1. On the basis of the three-dimensional frictional elastic contact boundary element method, introduce the bearing boundary element, the contact width Hertz correction theory and the plate element, and establish the bearing boundary element method;

[0218] Step 2. According to the finite long line contact elastohydrodynamic lubrication theory, the friction coefficient equation is derived, and the basic equation is dimensioned;

[0219] Step 3. Write the finite difference calculation program for calculating the elastohydrodynamic lubrication of rolling bearings with Fortran language;

[0220] Step 4. Coupling the bearing boundary element method and the finite long line contact elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com