Fractured steel frame progressive collapse analysis method based on column removing method

An analysis method and steel frame technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as unsatisfactory results, limited parameters, and long calculation time, achieving accurate results, easy convergence, and reasonable parameter settings. , the effect of short calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The method of the present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

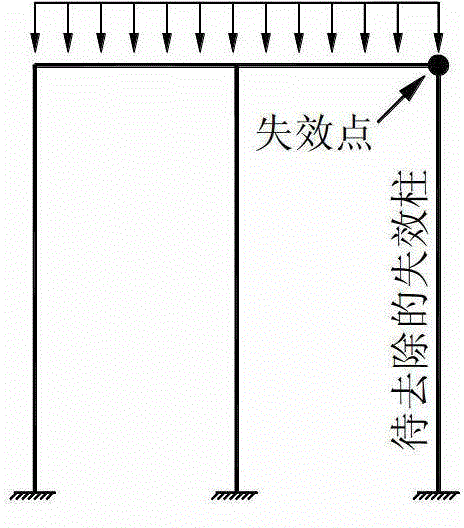

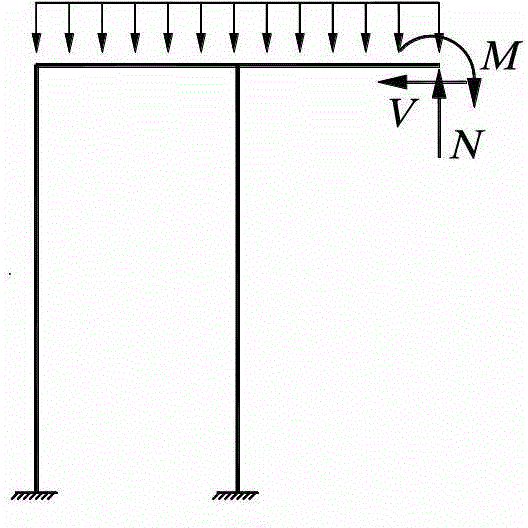

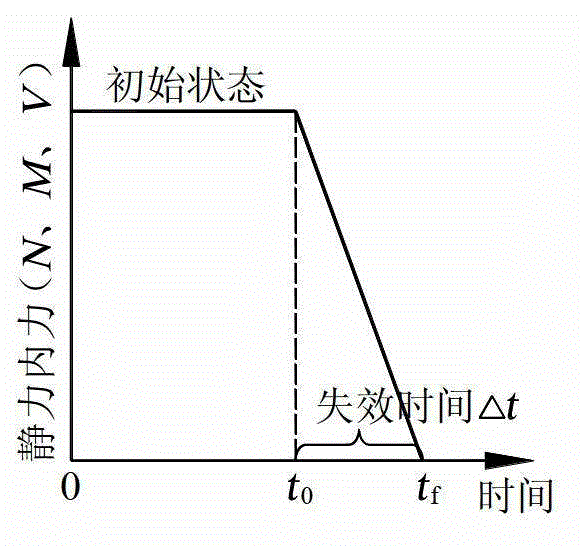

[0043] The continuous collapse analysis method of the steel frame with fracture based on the column extraction method of the present invention comprises the following steps:

[0044] 1) Establish an initial and complete steel frame finite element model and check the calculation. The specific steps are:

[0045] 11) Establish the initial and complete finite element geometric model of the steel frame to be analyzed in the Etabs design software. If the steel frame is a plane frame, divide the member according to the "four-section method", that is, divide the member into 0.1 times the length, 0.4 double length, 0.4 times length and 0.1 times length, if the steel frame is a space frame, divide the bar into 6 to 10 sections;

[0046] 12) Input the beam-column section layout of the steel frame in the Etabs design software to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com