Method for quickly simulating box type vibration clamp

A box and fixture technology, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as low computational consumption and unfavorable optimization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

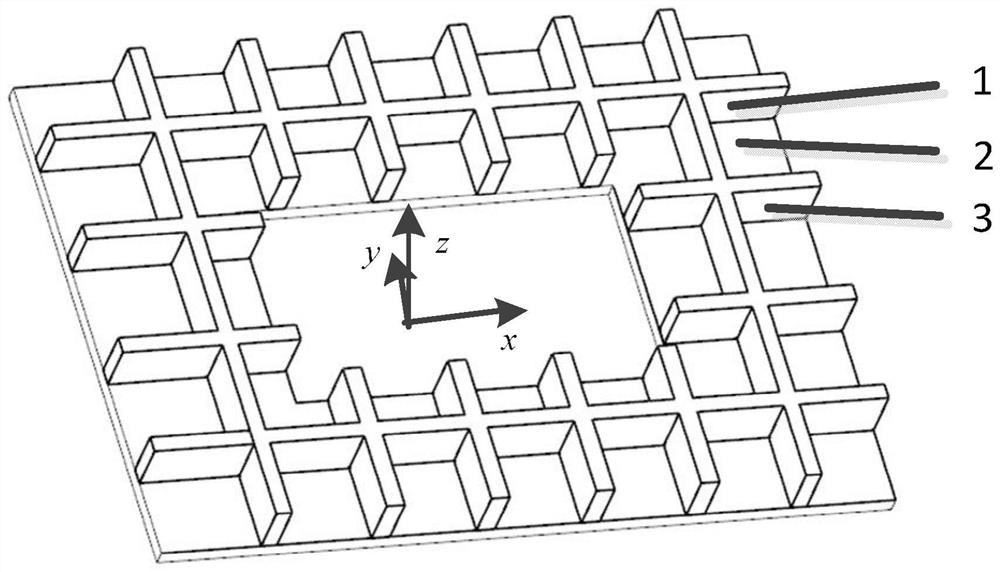

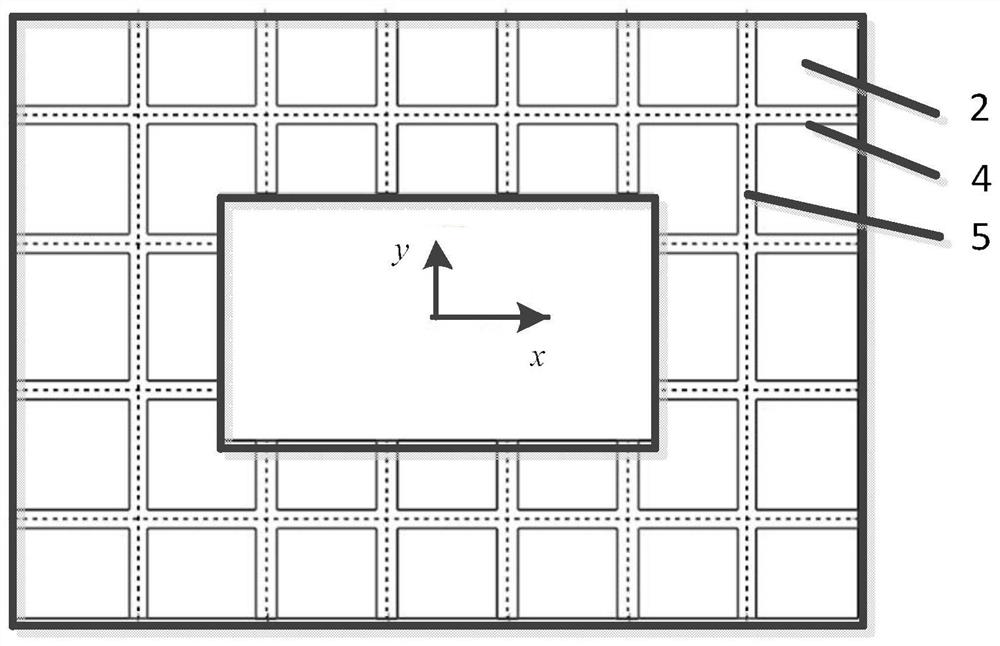

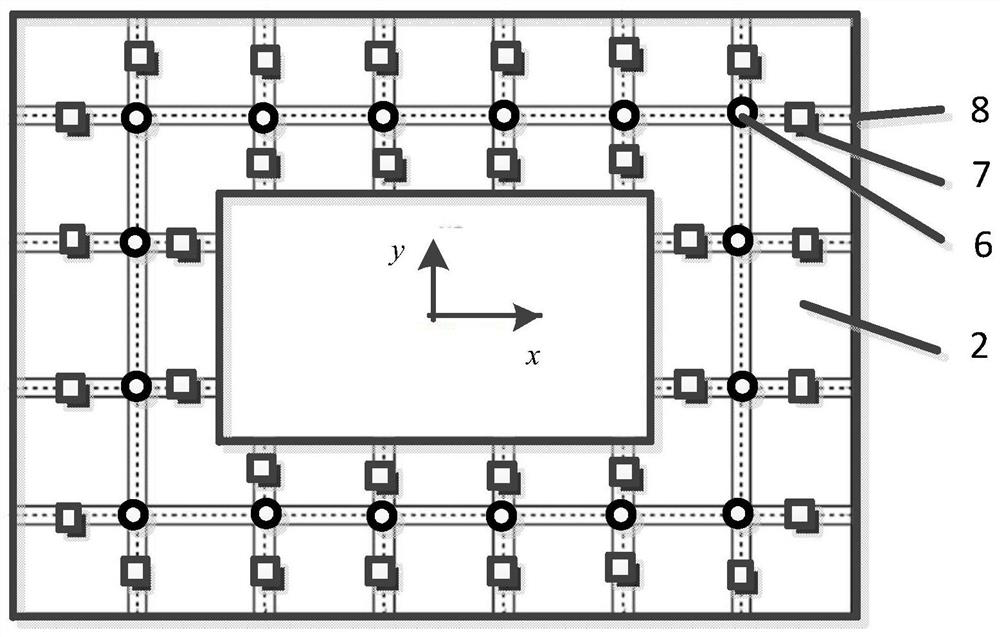

[0018] see Figure 1-Figure 4 . According to the present invention, adopt the following steps:

[0019] Step 1. Construct the bending beam model: Project the vertical plate 1 and the reinforcing rib 3 of the box-type vibration fixture on the upper surface of the bottom plate 2 to generate the projection of the quadrilateral 4 where the reinforcing rib 3 and the vertical plate 1 intersect in series, and take the short side of the quadrilateral 4 The center line is used as the initial positioning line 5 connecting the intersection of the vertical plate and the reinforcing rib, and the bending beam model is constructed at the initial positioning line;

[0020] Step 2, build a simplified geometric model of the box-type vibration fixture: use the bending beam model to be equivalent to the stiffener 3 and the vertical plate 1, use the discrete grounding spring to approximate the stiffness of the bending beam model, and determine the spring positioning point through the initial posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com