A multifunctional pipe bending device for electric power engineering

A technology of electric power engineering and pipe bending device, which is applied in the direction of storage device, feeding device, positioning device, etc., can solve the problems of single function, lack of convenience of movement, etc., and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

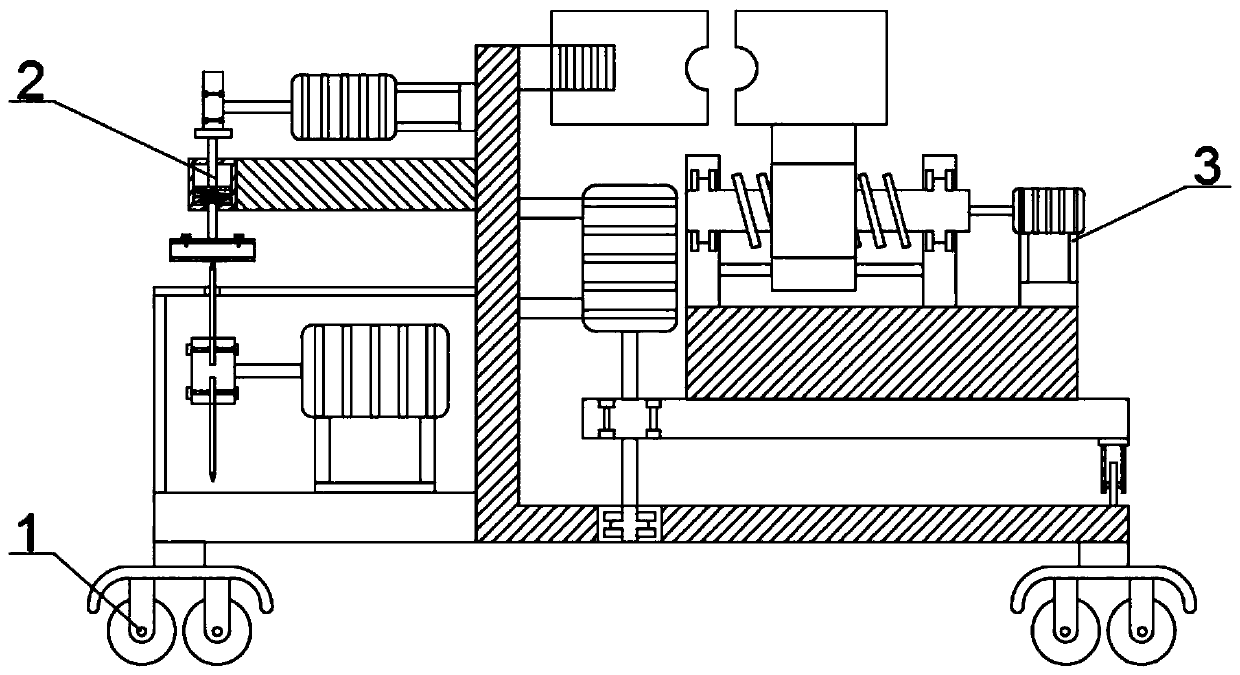

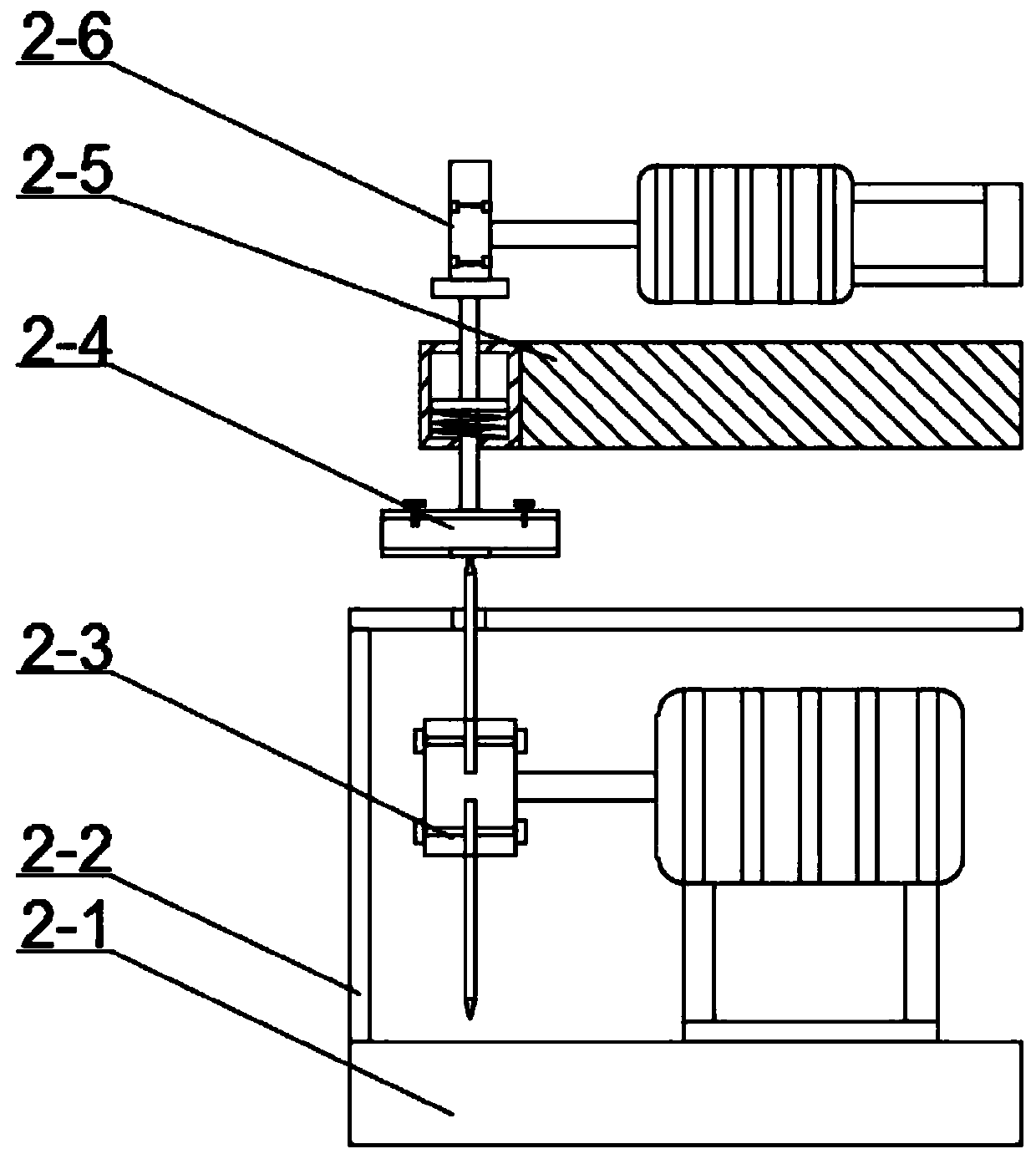

[0039] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 , Figure 13 To explain this embodiment, the present invention relates to a pipe bending device, more specifically, a multifunctional pipe bending device for power engineering, including a moving wheel mechanism 1, a pipe cutting mechanism 2, a pipe bending mechanism 3, and the device can For bending, the device can cut the pipe, the device can move, the device can automatically feed the pipe, and the safety is relatively high. The device can bend pipes of different sizes, and the device can replace the cutter.

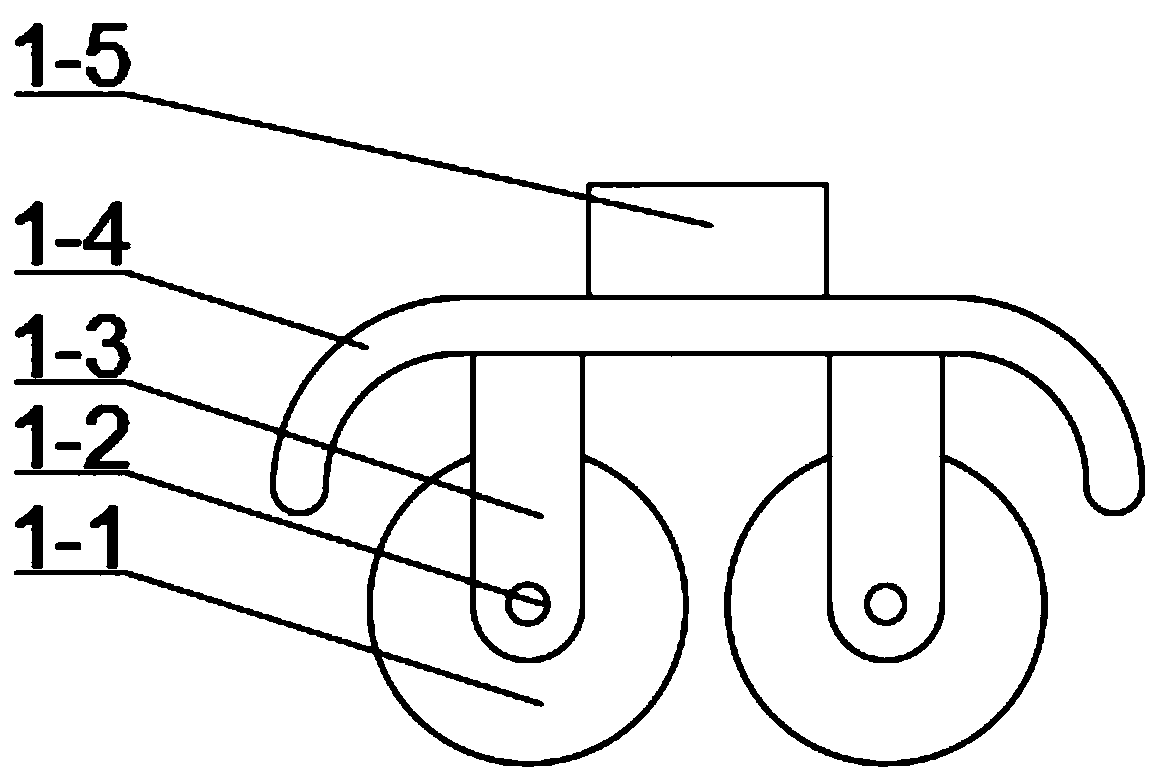

[0040] The moving wheel mechanism 1 includes a moving wheel body 1-1, a moving wheel fixing rod 1-2, a moving wheel leg 1-3, a moving wheel leg seat 1-4, a connecting seat 1-5, the moving wheel body 1-1 and The movable wheel fixed rod 1-2 is connected, and the connection method of the movable wheel body 1-1...

specific Embodiment approach 2

[0054] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 , Figure 13 This embodiment will be described. This embodiment will further describe the first embodiment. The number of the moving wheel mechanism 1 is four.

specific Embodiment approach 3

[0056] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Picture 9 , Picture 10 , Picture 11 , Picture 12 , Figure 13 This embodiment will be described. This embodiment will further explain the first embodiment. The material of the spring 2-4-5 is high carbon steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com