A batch non-destructive handling device for cylinders

The technology of a handling device and a cylinder is applied in the field of non-destructive handling of cylinders in batches, which can solve the problem that production efficiency and safety cannot be taken into account, and achieve the effect of simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

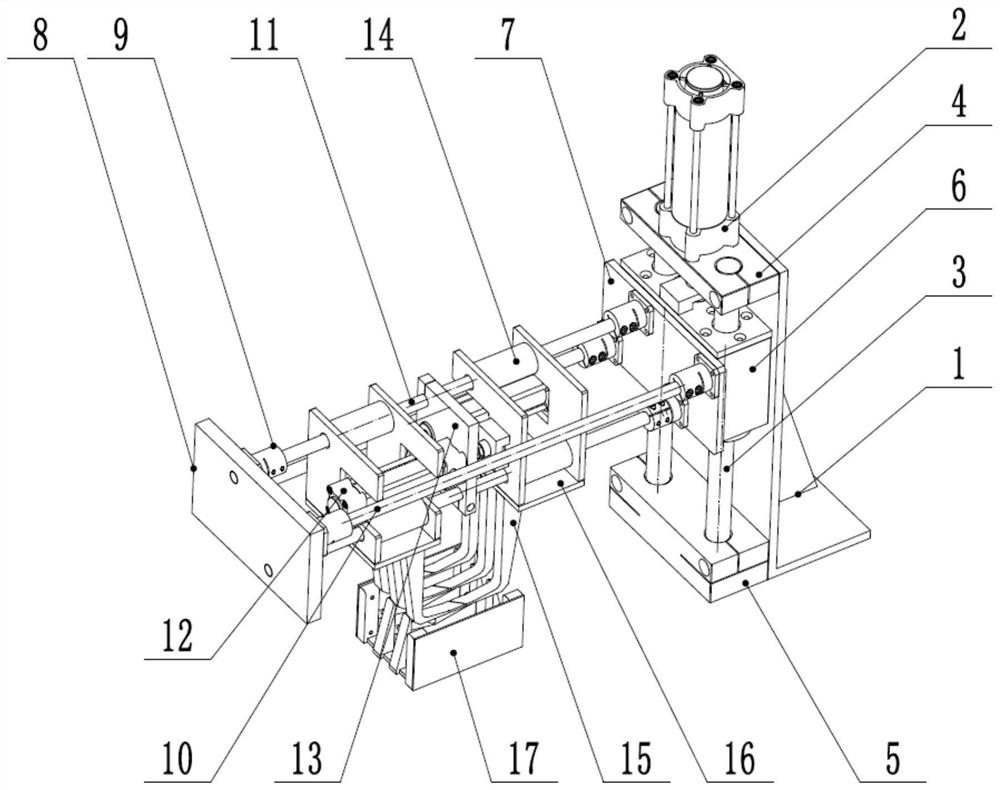

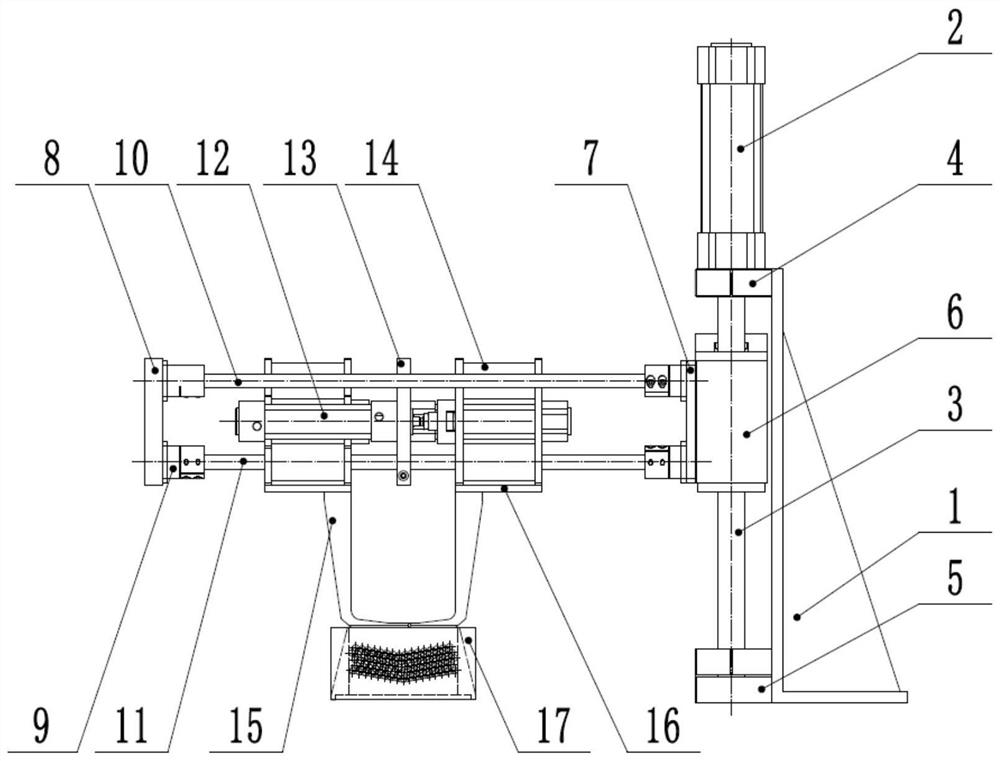

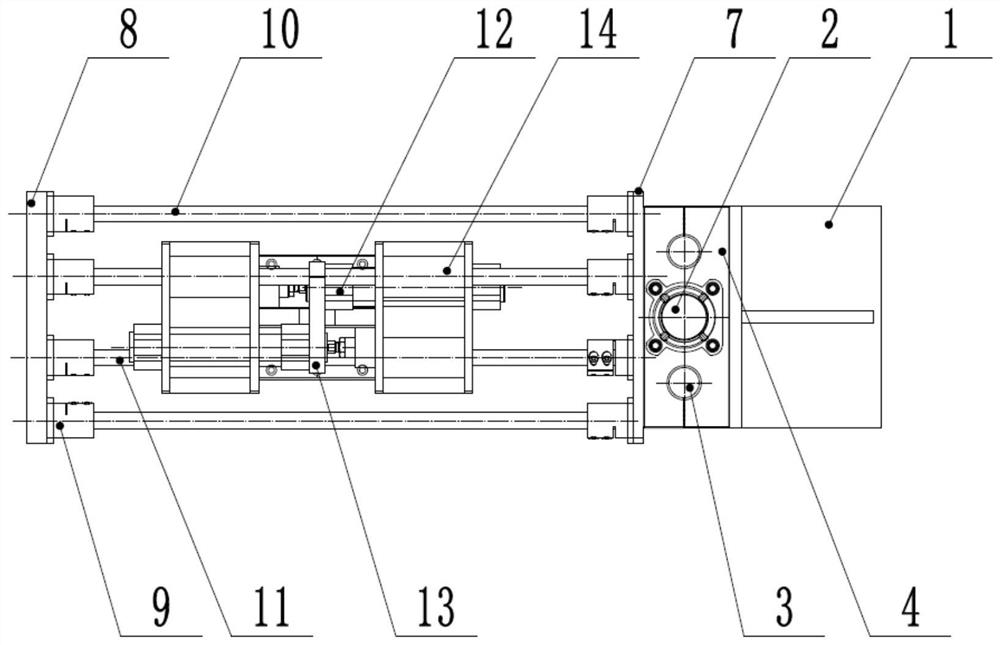

[0029] Such as Figure 1 to Figure 6As shown, a batch non-destructive handling device for cylinders of the present invention includes a frame 1 and a grid-type material box 17, and a lower support 5 and an upper support 4 are arranged on the side plate of the frame 1, and the upper support The seat 4 is located directly above the lower support 5, and the first guide shaft 3 is arranged between the upper support 4 and the lower support 5, and the two ends of the first guide shaft 3 are connected with the upper support 4 and the lower support respectively. 5 connection, the first guide shaft 3 is two, and the two first guide shafts 3 are respectively located on both sides of the central axis of the upper support 4 and the lower support 5, and the top of the upper support 4 is provided with a lift Cylinder 2, lifting cylinder 2 is the prior art, can be purchased on the market, the output end of the lifting cylinder 2 is provided with a first slider 6, and the first slider 6 is sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com