A circuit breaker phase column assembly method

An assembly method and circuit breaker technology, applied to circuits, electrical components, electric switches, etc., can solve the problems of large dispersion, out-of-tolerance synchronization, large dispersion of three insulating sleeves over-travel, etc., and achieve a wide adjustment range , Increase the effect of length adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

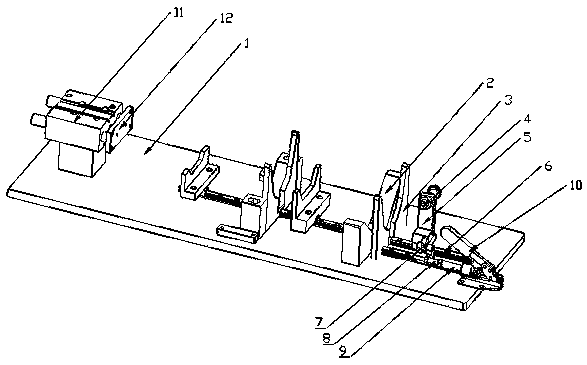

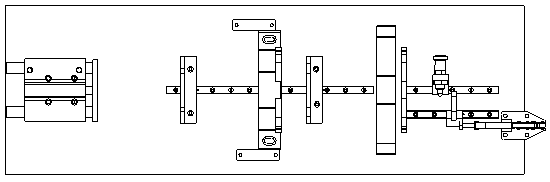

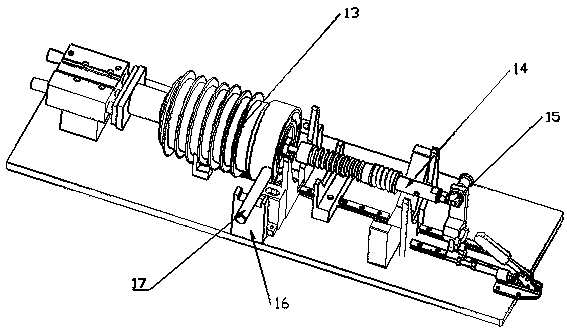

[0025] Such as figure 1 , figure 2 A circuit breaker phase column assembly tool is shown, the circuit breaker phase column includes an insulating sleeve and an insulating pull rod 14, and a conductive rod 17 is installed on the insulating sleeve. positioning installation, including

[0026] An assembly platform 1, assembly devices are installed on the upper end of the assembly platform 1, the assembly devices include

[0027] A reference unit, the reference unit includes a V-shaped block 2 installed on the upper end of the assembly platform 1 and used to support the insulating sleeve, the upper end of the V-shaped block 2 is an arc-shaped surface that fits the surface of the insulating sleeve, and the The reference plate 3 at the side end of the type block 2 and used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com