Production process of full-automatic air-cooled refrigerator fin evaporator

A technology of finned evaporator and air-cooled refrigerator, applied in heat exchange equipment and other directions, can solve the problems of difficult welding and deviation of the direction of the elbow, and achieve the effect of reducing the welding leakage rate, reducing the welding point, and reducing the hidden danger of leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

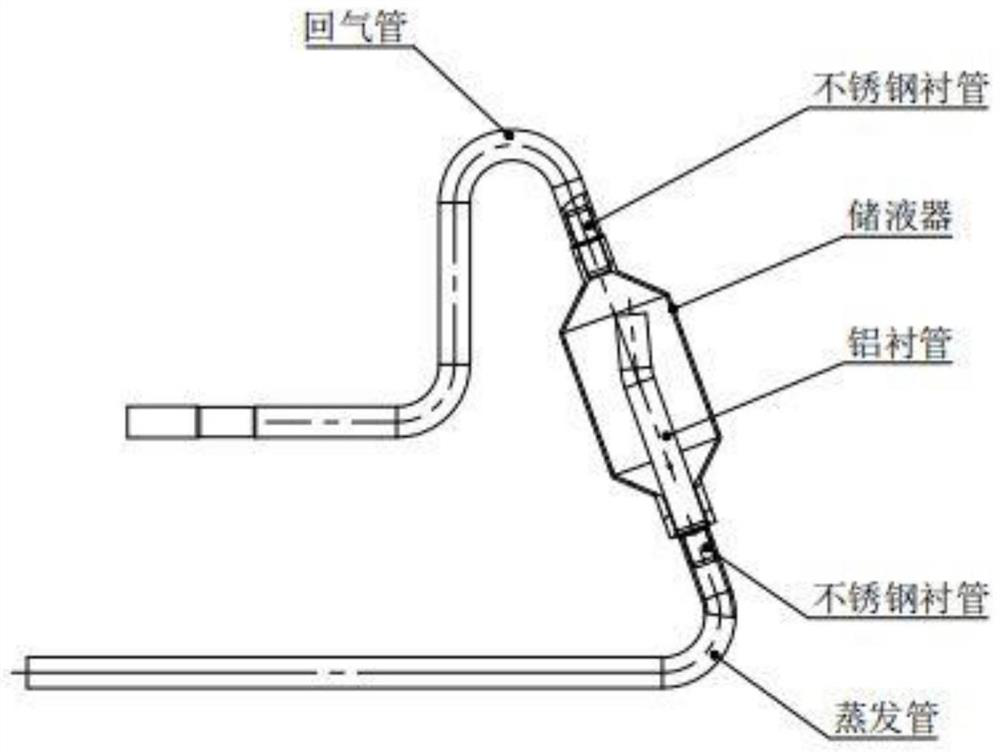

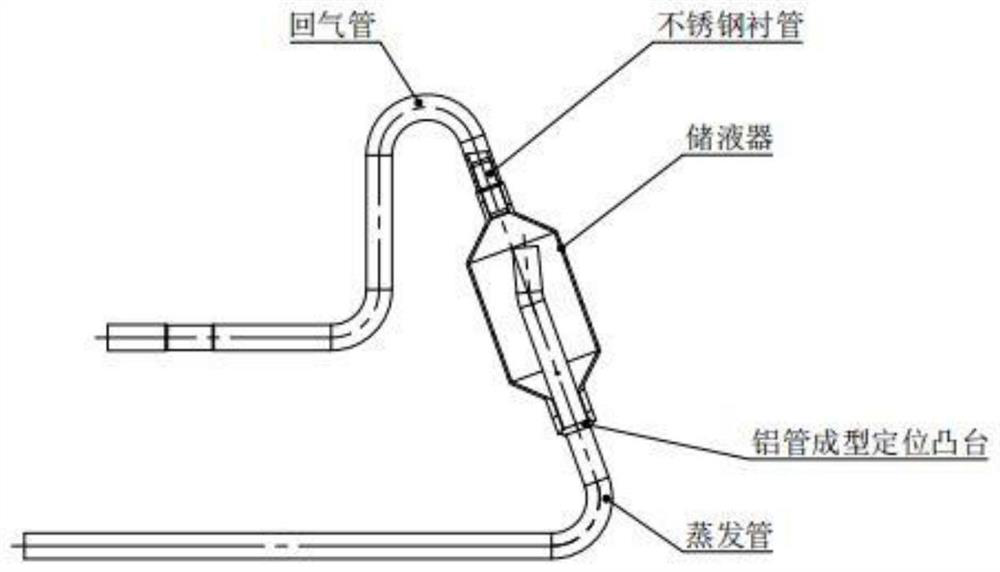

[0043] see Figure 1-9 As shown, the present embodiment is a production process of a fully automatic air-cooled refrigerator finned evaporator, comprising the following steps:

[0044] Step 1: The disc-shaped aluminum tube passes through the straightening machine, straightens according to the set size, and then blanks. The blanked material becomes an aluminum straight tube, and the thin aluminum sheet in the shape of a roll is stamped into a fin. ;

[0045] Step 2: The aluminum sheet is discharged into the mold of the equipment by an automatic sheet arrangement machine, and then the aluminum tube is filled with alcohol or water to expand the tube, so that the aluminum tube expands and combines with the fins;

[0046] Step 3: The straight aluminum tubes and fin blanks that have passed through the expansion tube are placed on the tube bending machine. After the tube bending machine is started, the straight aluminum tubes and fins are folded into an M-shaped finned evaporator s...

Embodiment 2

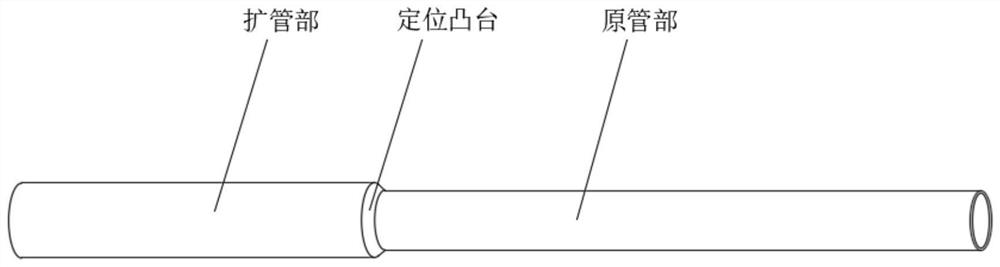

[0051] see Figure 4-9 As shown, this embodiment is a boss forming equipment, including a conveyor 101, a boss forming box 102, the boss forming box 102 is installed on one end of the top of the mounting frame 103, and the other end of the top of the mounting frame 103 is equipped with a mounting plate 104 , a forming cylinder 105 is installed on the top of the mounting plate 104 , and the conveyor 101 and the forming cylinder 105 are respectively located at both ends of the boss forming box 102 .

[0052] One side bottom of the boss forming box 102 is equipped with a feeding cylinder 106, the top of the boss forming box 102 is equipped with a positioning cylinder 107, and the top of the boss forming box 102 is installed with several guide posts 108, and several guide posts 108 They are located on both sides of the positioning cylinder 107 respectively.

[0053] The inner cavity of the boss forming box 102 is provided with a positioning seat 110, the top of the positioning se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com