Smelting method for producing high-silicon low-carbon manganese-copper alloy at a time through submerged arc furnace

A smelting method and technology of a submerged arc furnace, which are applied in the smelting field of producing high-silicon and low-carbon manganese-copper alloys in a one-time submerged arc furnace, can solve the difficulty of high temperature operation of the furnace surface by workers, unstable quality of alloy products, affecting normal smelting, etc. problems, to achieve good market prospects, reduce steel smelting costs, and increase the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

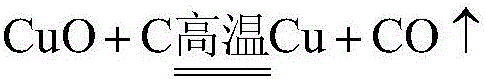

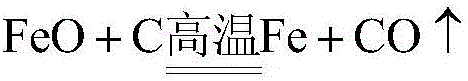

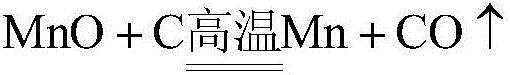

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Configure mixed manganese ore with manganese content greater than 38%, silica greater than 39%, and manganese-iron ratio of 10.5, with a particle size of 10mm-80mm; 2.5%-4% copper ore, with a particle size of 10mm-80mm Add manganese ore and copper coke with a total weight of 20%-27%, particle size 25mm-40mm; add silicon 7%-13%, particle size 10-80mm; add 1%-3% dolomite and fluorite to ensure liquid alloy Alkalinity in the medium, add 2.5%-4% of copper raw material, its particle size is 10mm-50mm (copper ore or the same amount of metallic copper); the total amount of phosphorus in the raw material is less than 0.04%, and the purpose of adding dolomite is to adjust the liquid state Alkalinity in the alloy, the purpose of adding fluorite is to increase the fluidity of the slag.

[0024] Continuously add the above raw materials into the submerged arc furnace and smelt at 1600℃-2500℃ for 200-300 minutes, pour the liquid alloy into the ladder ladle and discharge the slag, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com