Assembly device for inserting hard bar into slot type board body and insertion method

An assembly device and hard board technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low production efficiency, manual threading cannot guarantee threading quality, poor product quality uniformity, etc., and achieve the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

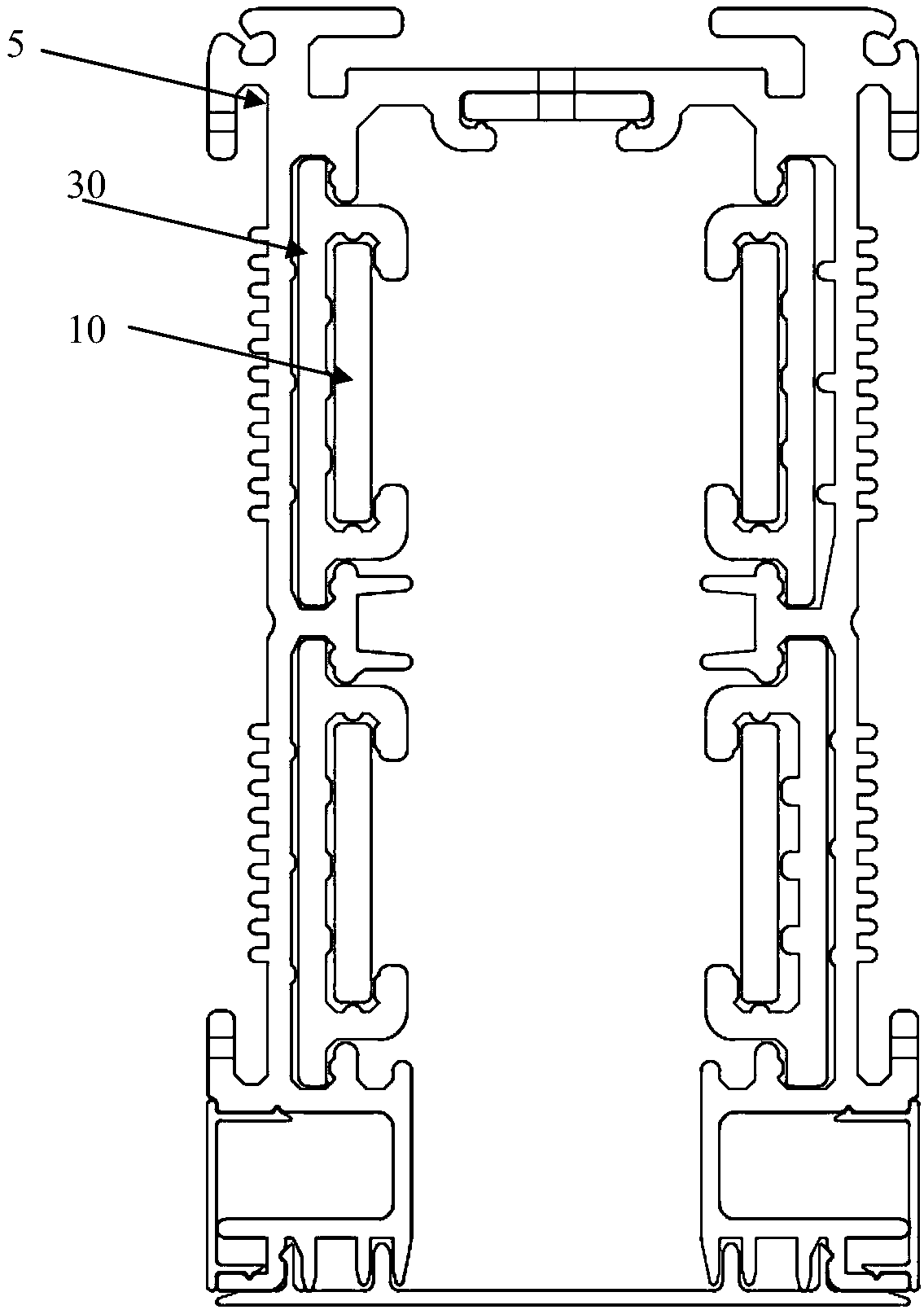

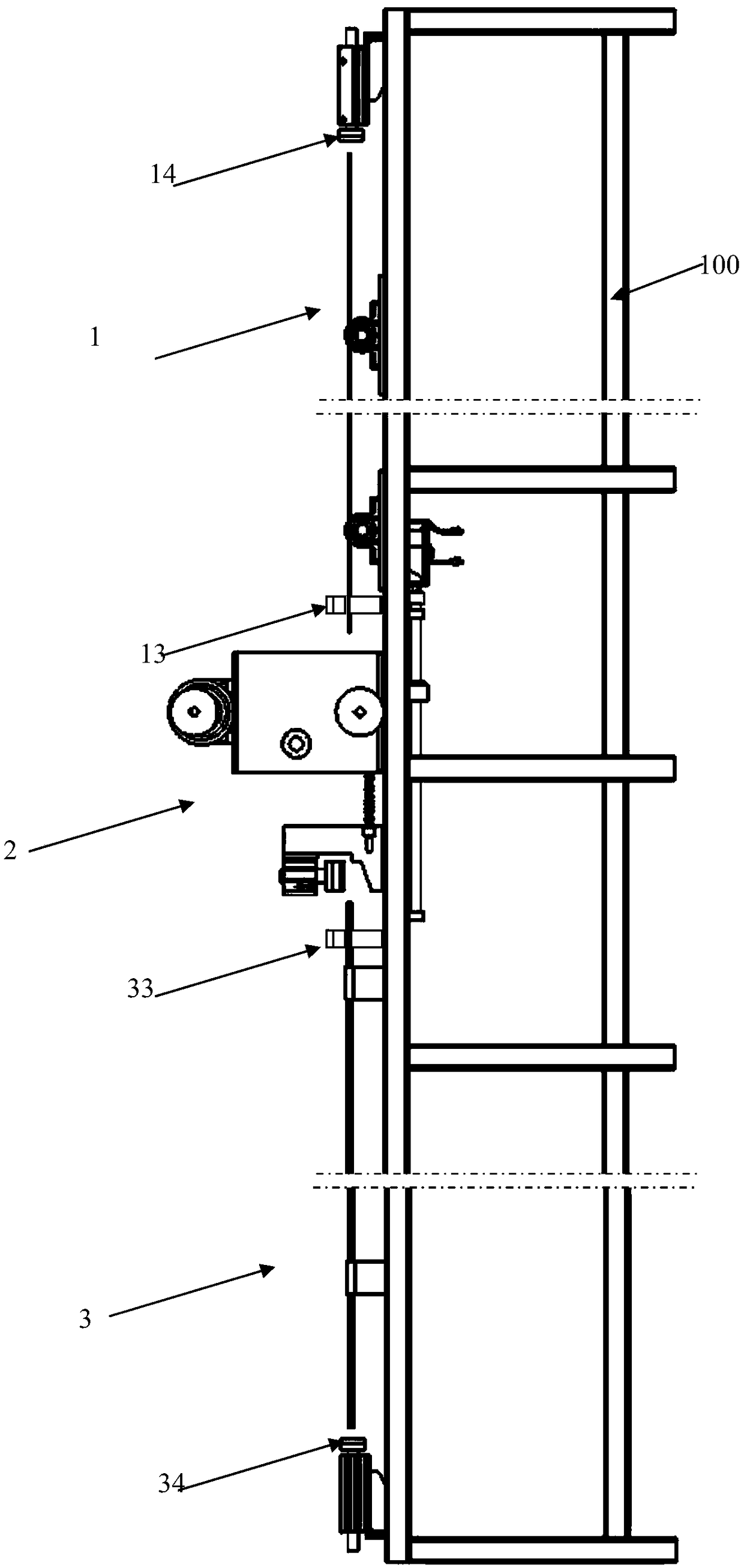

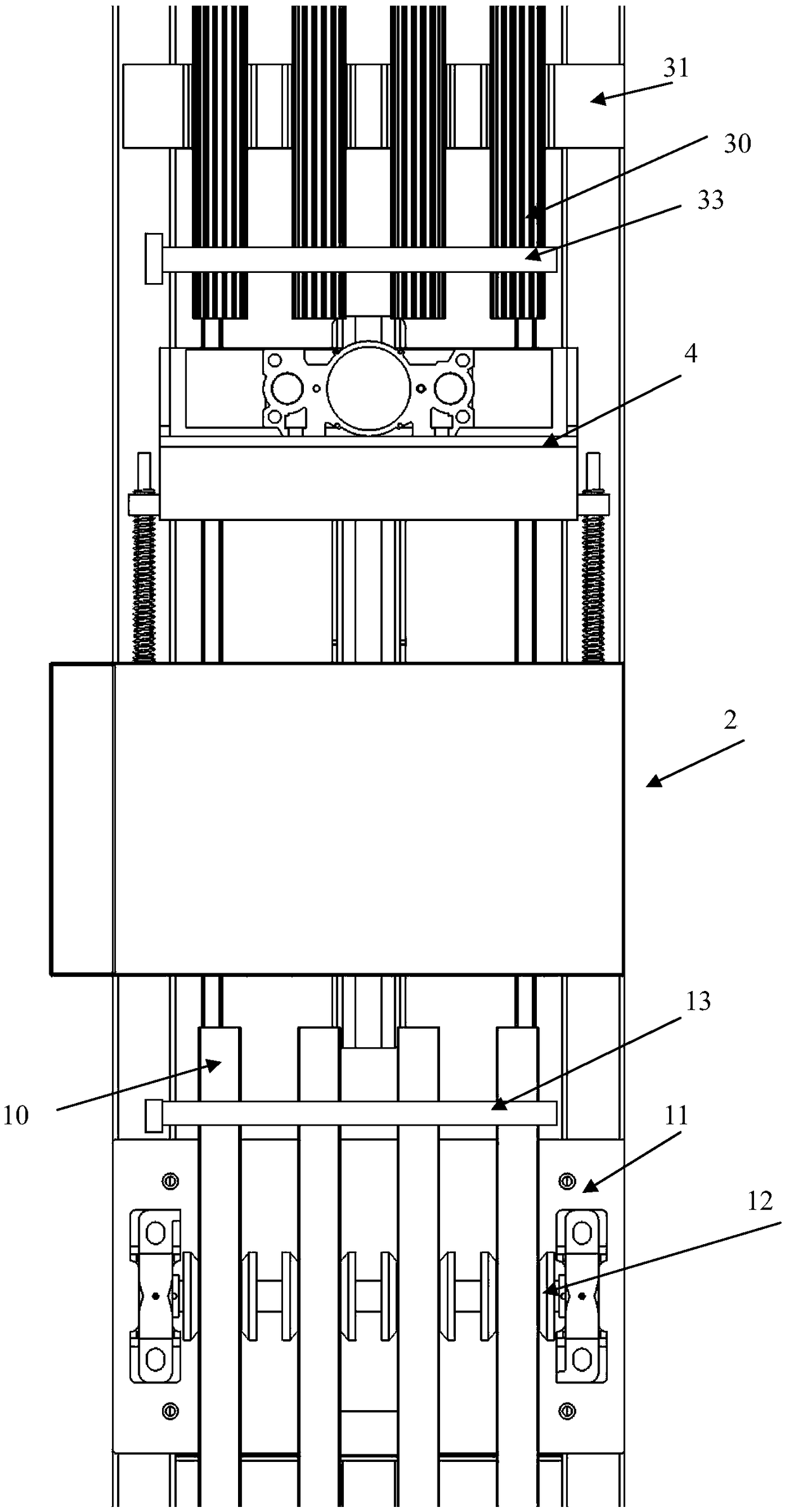

[0044] The assembly device for inserting the hard slats into the trough-type board body of the present invention, if the hard slats are copper bars, and the trough-type boards are insulating boards, the following is an example of inserting the copper bars into the insulating boards. Explain that the assembly device includes a strip support part 1, a docking part 2, and a board support part that can simultaneously support and position multiple insulating plates, which are arranged on the base frame 100 in sequence along the axial direction. The support part 3; the docking part includes a carrier 20 that is driven to move back and forth relative to the base frame 100, a plurality of docking ports 20 fixedly arranged on the carrier, and a roller-type slat that is fixedly arranged at the front of the docking port to convey Mechanism, the front guide seat 21, which is arranged at the front of the slat conveying mechanism and corresponds to the docking part, is used to guide the copp...

Embodiment 2

[0048] Wherein, the slat conveying mechanism includes a power conveying roller 23 arranged below the copper bar conveying track, and a plurality of non-powered pressure rollers 24 arranged in one-to-one correspondence with the docking parts and driven to move up and down. The power conveying roller extends along the vertical direction of the copper bar, and can support multiple copper bars at the same time. The power conveying roller is driven by a motor, and the non-powered pressure roller is fixedly arranged on the movable plate 25. The movable plate Driven to move up and down relative to the above-mentioned power conveying roller, preferably, the movable plate shown is driven to move up and down by a cylinder 27 fixed on the top plate, and a supporting spring 26 is arranged between the movable plate and the top plate, and the The holding spring provides pressing force, and the cylinder is used to move away to make the copper bar easy to enter.

[0049] Using the roller pres...

Embodiment 3

[0054] At the same time, in order to complete the positioning of the insulating board, it also includes an insulating board end positioning pressing plate 41 which is located at the rear of the docking port and is driven to move up and down to press and position the front end of the insulating board. The insulating plate end positioning supporting plate 42 provided correspondingly by the end positioning pressing plate can complete the positioning of the front end of the insulating plate by using the profiling notch design of the insulating plate positioning supporting plate and the corresponding insulating plate end positioning pressing plate to ensure the insertion time stability.

[0055] In order to improve the safety of equipment operation and ensure a reasonable pressing point, two horizontally extending rear rods 40 are arranged at the rear end of the carrier, and the front and rear of the carrier can be arranged on the rods. The moving one is provided with a slide frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com