Device for automatically detecting sealing performance

A sealing performance, automatic detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc. problem, to achieve the effect of convenient operation, efficient and rapid detection of air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

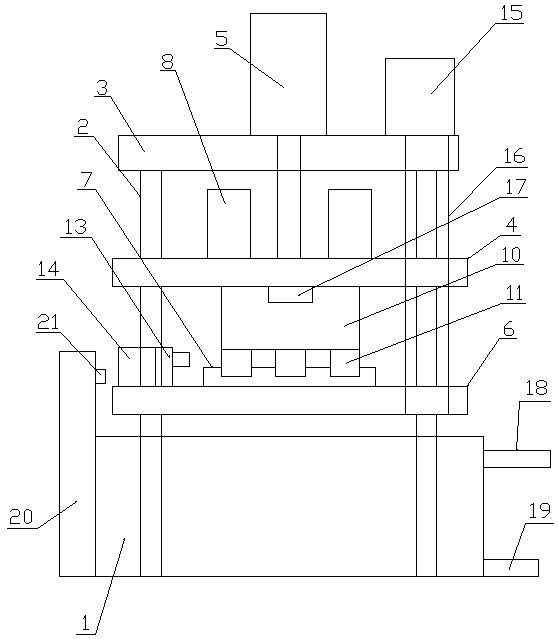

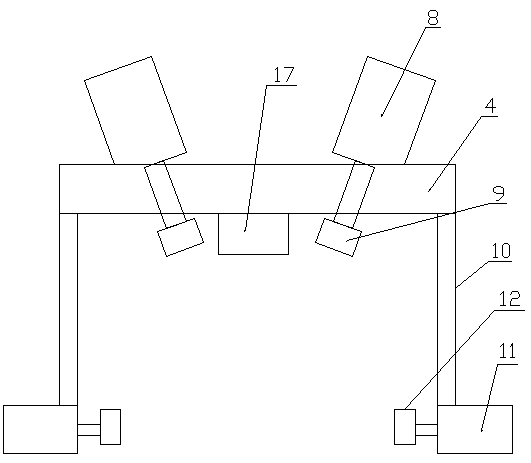

[0013] Such as figure 1 with 2 As shown, this embodiment provides a device for automatic detection of sealing performance, including a water tank 1 with a bottom, and four sliding rods 2 arranged in a square shape are arranged in the water tank 1, and the four sliding rods 2 extend upwards on the water tank 1 Above; four sliding rods 2 tops are provided with a top plate 3, four sliding rods 2 are located below the top plate 3 and are covered with a sliding plate 4, and the middle of the top of the top plate 3 is provided with a push-down oil cylinder 5, and the slide plate 4 is connected to the bottom of the push-down oil cylinder 5; A sliding rod 2 is located at the bottom of the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com