Diaphragm airtightness detection automation device and use method thereof

A technology of air tightness detection and automatic device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the acceleration and deceleration rate of fluid, etc., can solve the problem of small detection amount, poor detection effect, inconvenience and intelligence question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

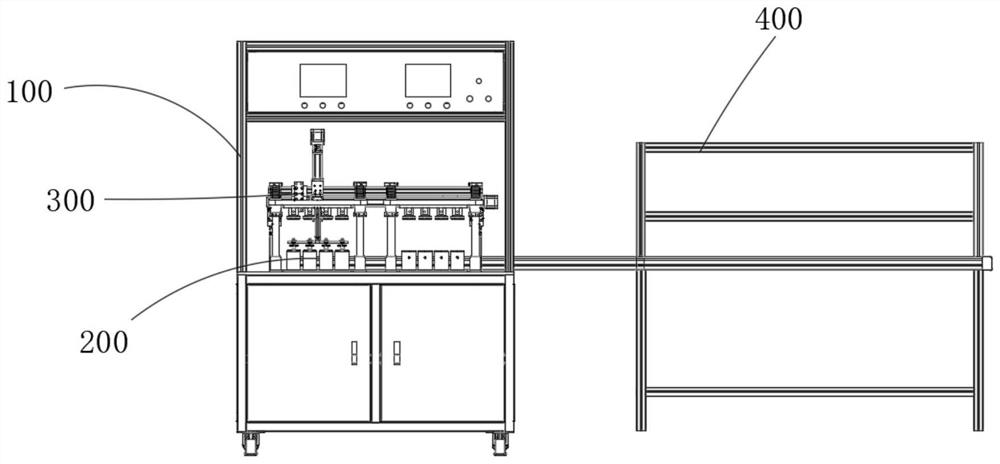

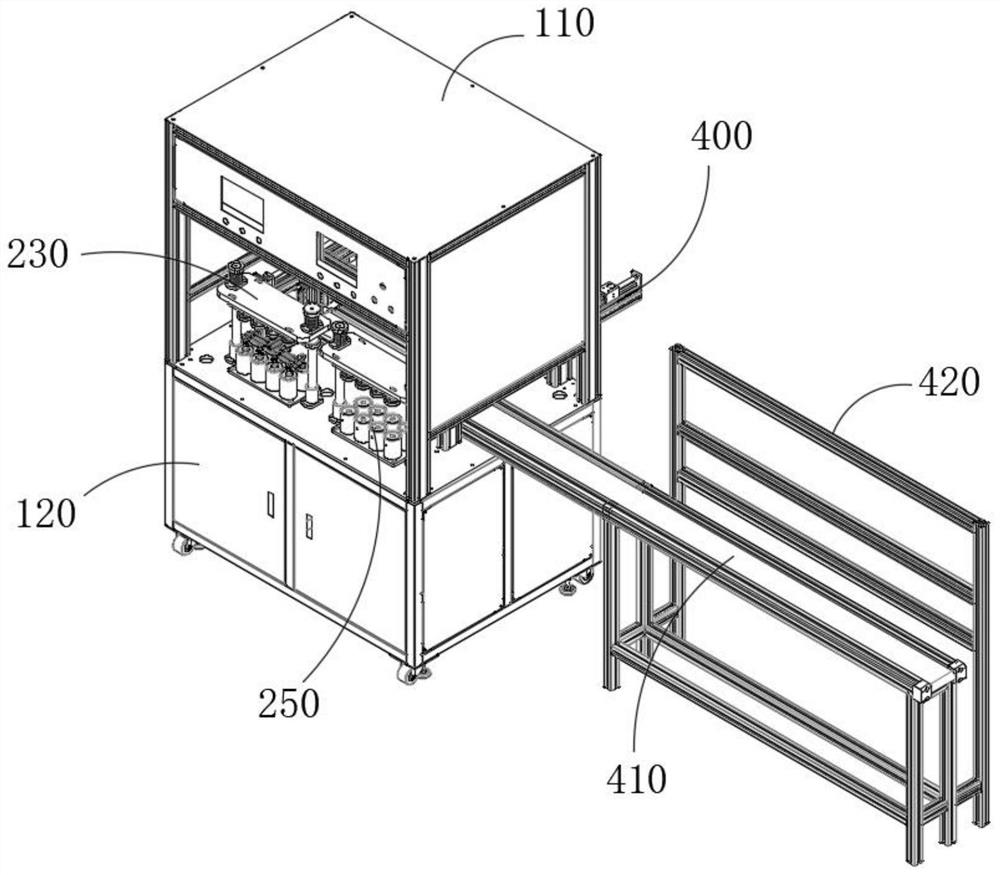

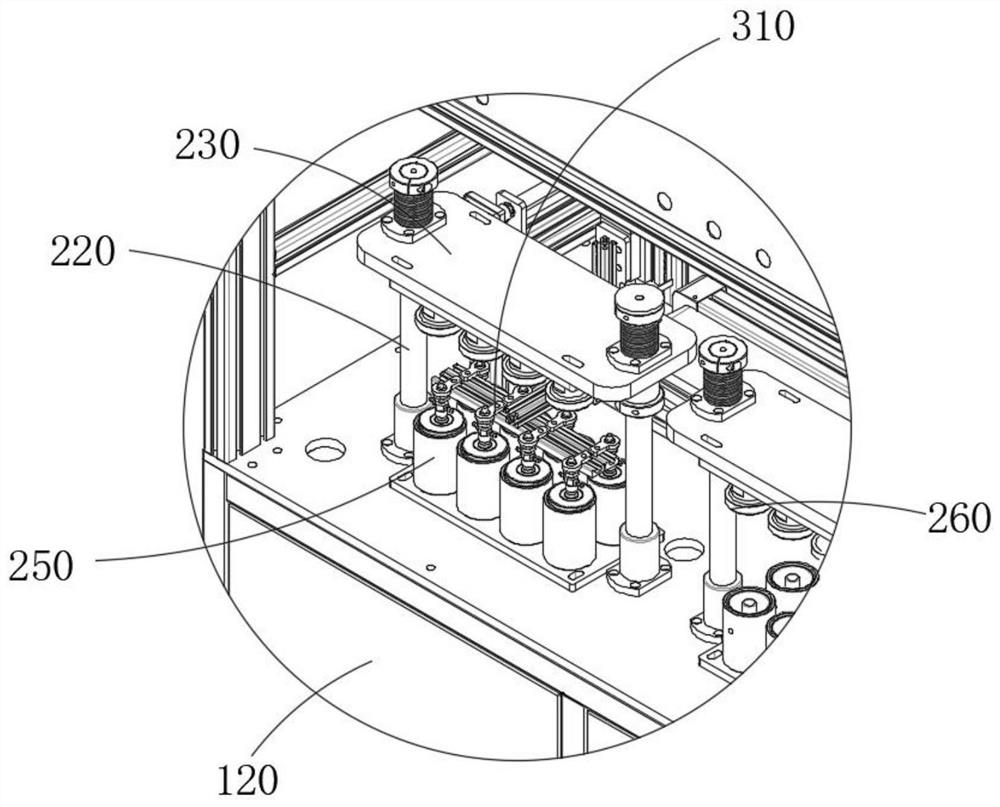

[0039] Refer to attached Figure 1-Figure 6 As shown, a diaphragm airtightness detection automation device of this embodiment includes a frame 100, a positioning tool 200, a detection mechanism 300 and a transmission mechanism 400, and the positioning tool 200 and the detection mechanism 300 are located in the frame 100, and the machine The frame 100 includes an upper frame 110 and a lower platform 120, and the detection mechanism 300 includes a three-axis translation stage 310, a horizontal support 320 and a vacuum suction cup 330, and the three-axis translation stage 310 is installed in the upper frame 110, and the three-axis translation stage 310 is installed with a horizontal Support 320 and vacuum suction cup 330, positioning tool 200 is installed on the table of lower stand 120, and positioning tool 200 comprises cylinder 210, optical axis 220, pressure plate 230, connecting plate 240, lower jig 250 and upper jig 260, and cylinder 210 is installed In the lower platform 1...

Embodiment 2

[0046] Refer to attached Figure 1-Figure 6 As shown, a method for using a diaphragm airtightness detection automation device in this embodiment, the method includes the following steps:

[0047]S100, placing the membrane to be detected on the lower jig 250;

[0048] S200, the upper jig 260 moves downward to press the diaphragm, and vacuumizes the inside of the upper jig 260;

[0049] S300, the gas detection machine detects the air tightness of the diaphragm, and controls the upper fixture 260 to rise;

[0050] S400, the three-axis translation stage 310 drives the vacuum suction cup 330 to absorb the diaphragm, and places it on the conveyor belt 410 or the waste area.

[0051] The specific method of step S300 of this embodiment is that the gas detector vacuumizes the upper fixture 260. If the diaphragm leaks, the pressure in the upper fixture 260 will not change, and the gas detector detects the pressure value to determine whether the diaphragm is Leakage, after the detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com