Air tightness pressure-maintaining test apparatus

A technology of pressure testing and equipment, which is applied in the field of airtight pressure-holding testing equipment, can solve the problems of high manufacturing and use costs and complex structures, and achieve the effects of low manufacturing and use costs, simple structure, and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below the attached figures and further explain the technical solution of the present invention through the specific embodiments.

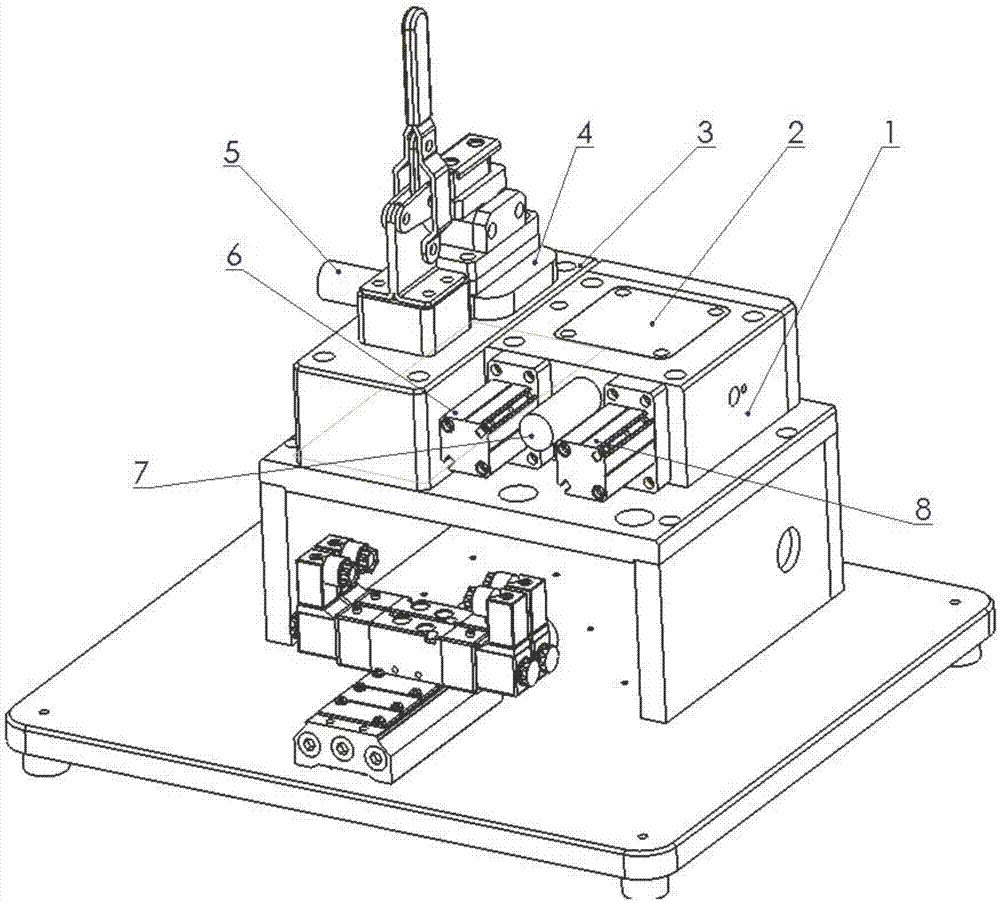

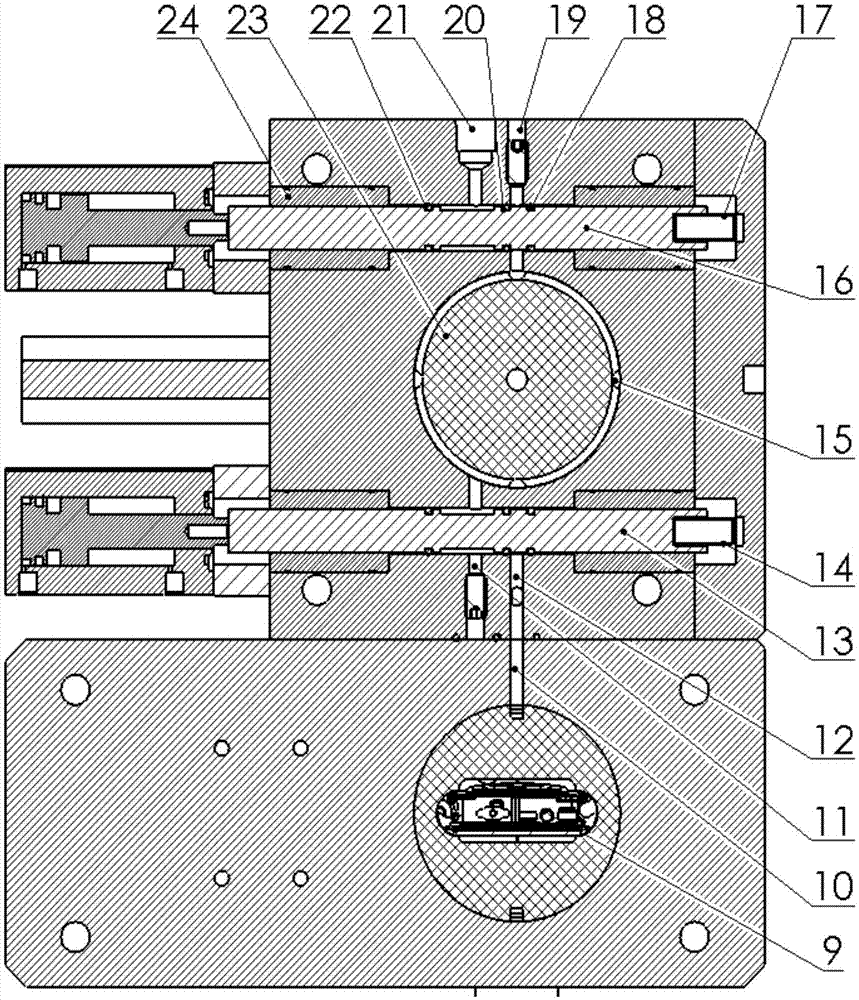

[0029] like figure 1 It is shown in, this embodiment provides a gas tightly pressure -keeping test equipment. Qi tight pressure preservation testing equipment includes the first sealing cavity 1 and the second sealing cavity 3. Among them, And used to protect the pressure and provide gas to the second sealing cavity, the second sealing cavity 3 is used to place the test device 9.

[0030] The connection tube road between the first sealing cavity 1 and the gas source and the connecting pipeline between the first sealing cavity 1 and the second sealing cavity 3 have control devices.Essence

[0031] It also includes the first pressure detection device 7 and the second pressure detection device 5 used to detect the first sealing cavity 1 and the second sealing cavity 3.

[0032] This application can be tested quickly and accurately through the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com