Fastening belt forming mold

A technology for fastening belts and molding dies, which is applied in the field of stamping dies, can solve the problems of increasing mold investment and maintenance costs, material waste, time-consuming, etc., and achieves high compression molding efficiency and product quality, reduced manufacturing costs, and excellent quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

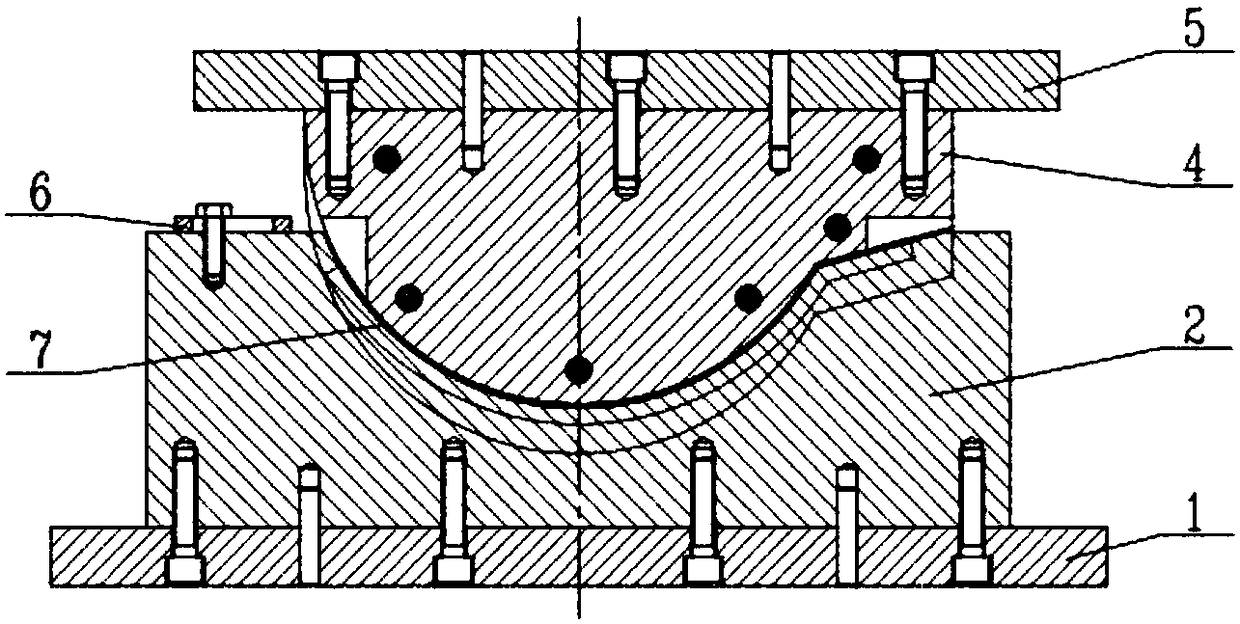

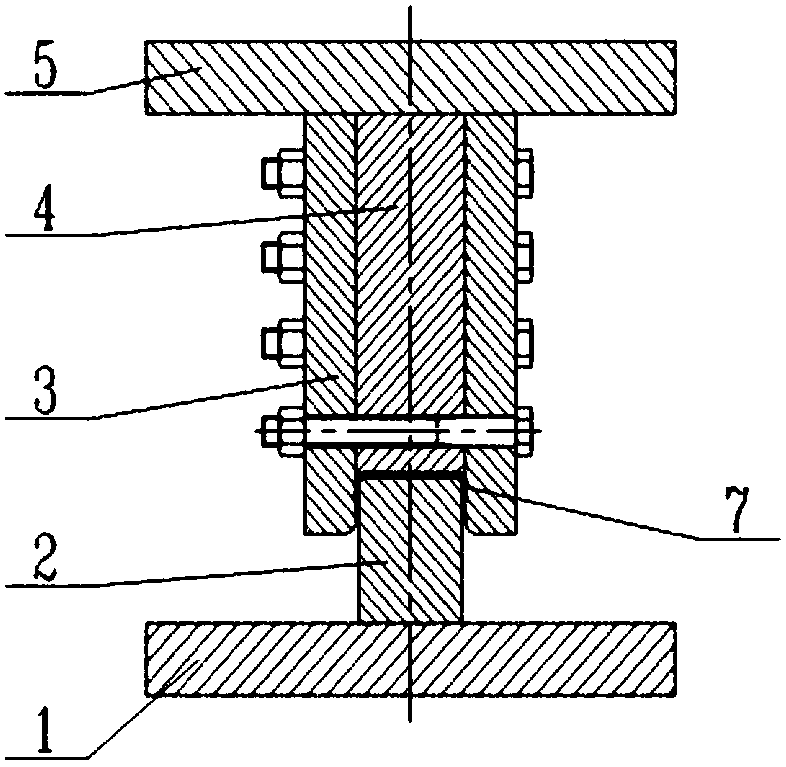

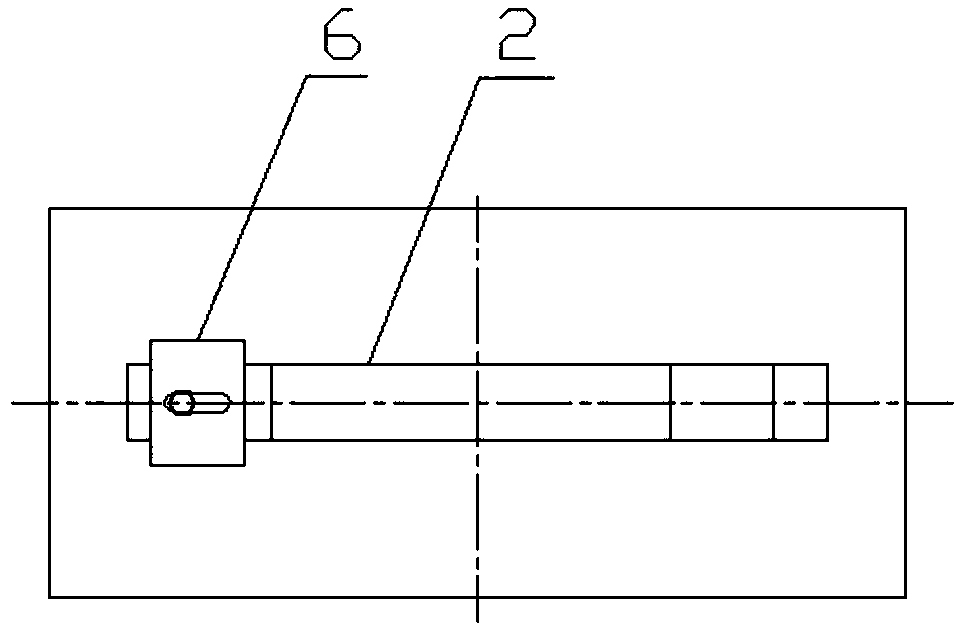

[0016] Such as figure 1 As shown, the structure of this embodiment includes a lower template 1, a die 2, a punch 4, a punch side plate 3, and an upper template 5, the die 2 is connected with the lower template 1, and the punch 4 is connected with the upper template 5 A punch side plate 3 is respectively arranged on both sides of the punch 4, and the lower end faces of the two punch side plates 3 are lower than the lower end faces of the punch 4, and the upper surface of the die 2 is a downwardly concave arc surface 9, the convex The lower surface of the mold 4 is a downwardly protruding arc surface 11, and the arc surface 9 of the female die is the same as the arc surface 11 of the punch.

[0017] In this embodiment, the thickness of the female mold 2 is smaller than that of the male mold 4 , and the female mold 2 is located in the center below the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com