A method for optimizing the operation mode of volatilization kiln combining least squares support vector machine regression and particle swarm optimization

A technology of support vector machine and particle swarm optimization, which is applied in data processing applications, complex mathematical operations, instruments, etc., to achieve the effect of improving energy saving and emission reduction and suppressing large fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation scheme of the method for optimizing the operation mode of the volatilization kiln operating mode by integrating the least squares support vector machine regression and particle swarm optimization proposed by the present invention is described in detail as follows:

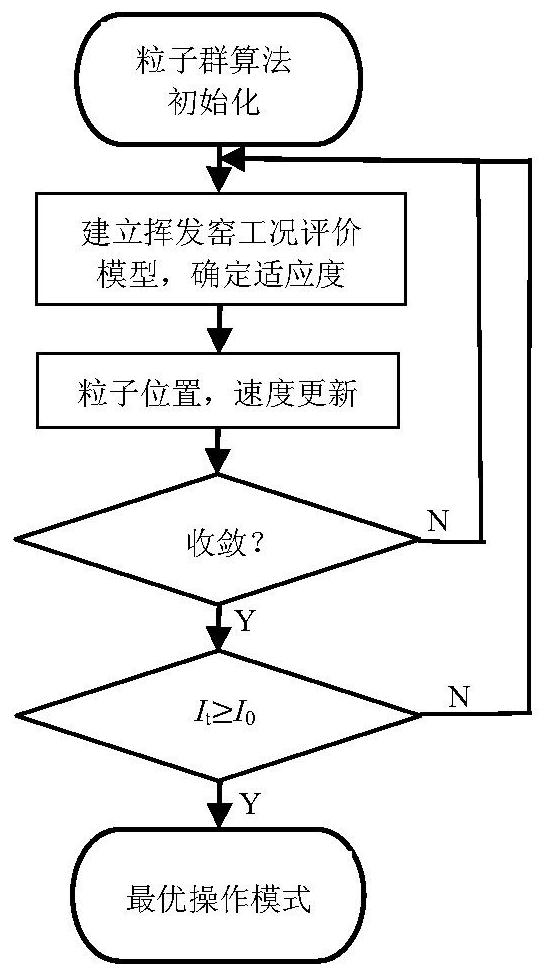

[0046] The optimization method for the operating mode of the volatilization kiln proposed by the present invention is divided into two parts:

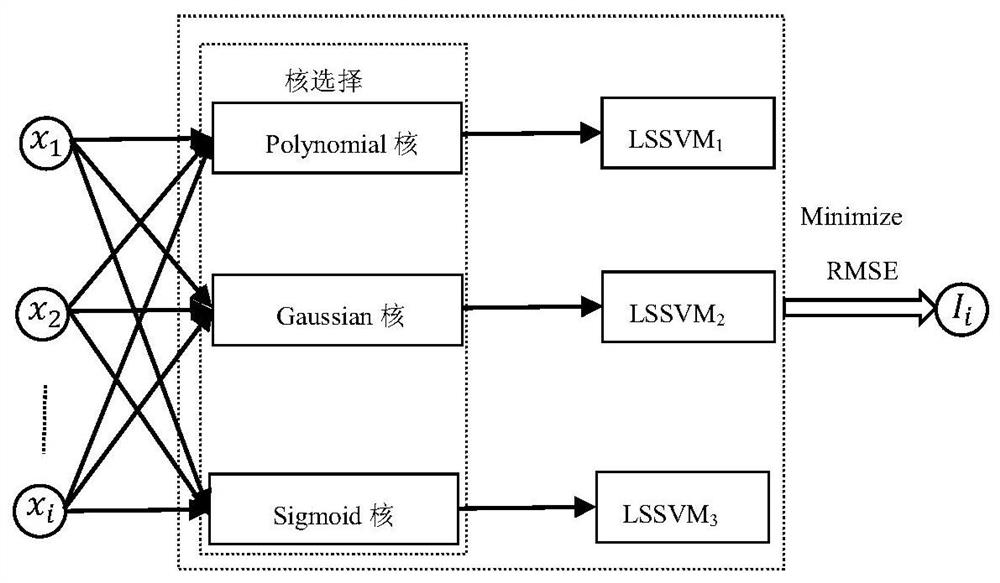

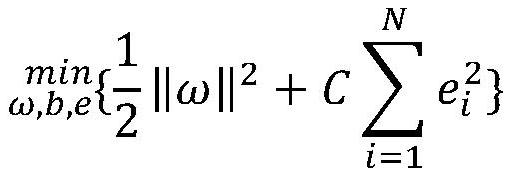

[0047] (1) Establish a working condition evaluation model of volatilization kiln based on least squares support vector machine

[0048] as attached figure 1 The working condition evaluation model of the volatilization kiln based on the least squares support vector machine is established as shown in the figure. The parameters that affect the prediction of the volatilization kiln process indicators include the kiln body speed, blast air pressure, blast air volume, negative pressure in the kiln, and the ratio of materials entering the kiln. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com