Improved genetic algorithm for flexible job shop scheduling with moving time

A technology of improved genetic algorithm and moving time, which is applied in the field of flexible job shop scheduling with moving time by improved genetic algorithm, and can solve problems such as the influence of moving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

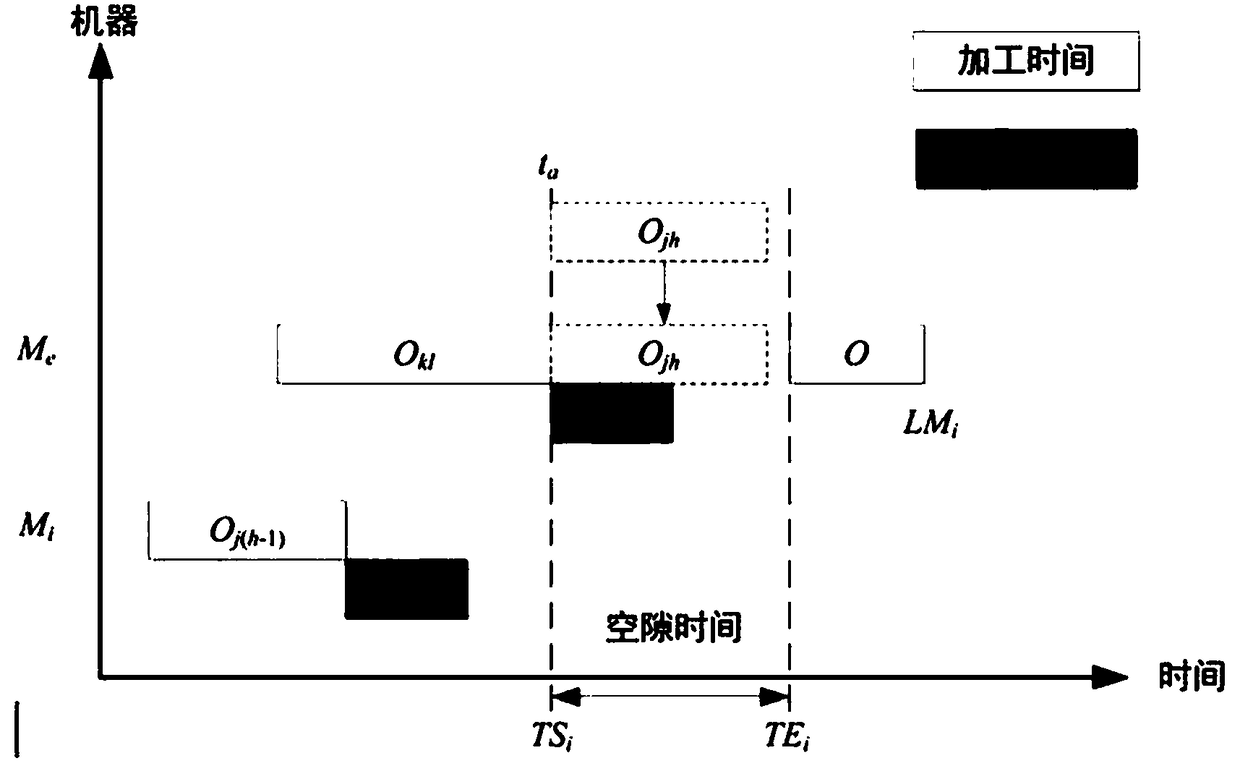

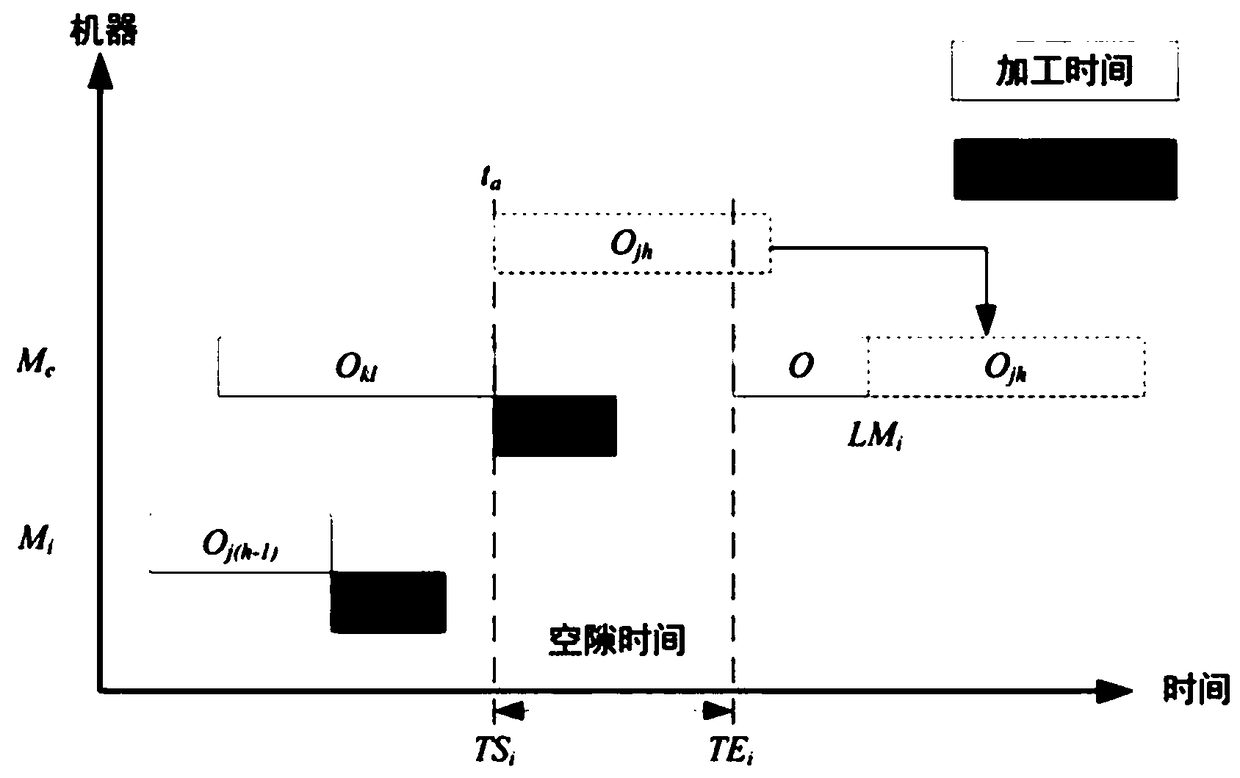

Method used

Image

Examples

Embodiment 1

[0059] The present invention solves the flexible job shop scheduling method with moving time for improving genetic algorithm, is characterized in that, comprises the following steps:

[0060] Step 1, set parameters; determine the population size P, the number of iterations G, and the crossover probability P c , variation probability P m Wait;

[0061] Step 2, population initialization, using random selection method to randomly generate population individuals;

[0062] Step 3: Calculate and evaluate the fitness value of each chromosome in the population, i.e. the target value, and compare its size. If the output condition is met or the approximate optimal solution is completed, the operation is completed; otherwise, step 4 is performed;

[0063] Step 4, use the tournament method to select and select the next generation population;

[0064] Step 5, perform crossover according to the crossover strategy for the chromosomal individuals satisfying the crossover probability in the...

Embodiment 2

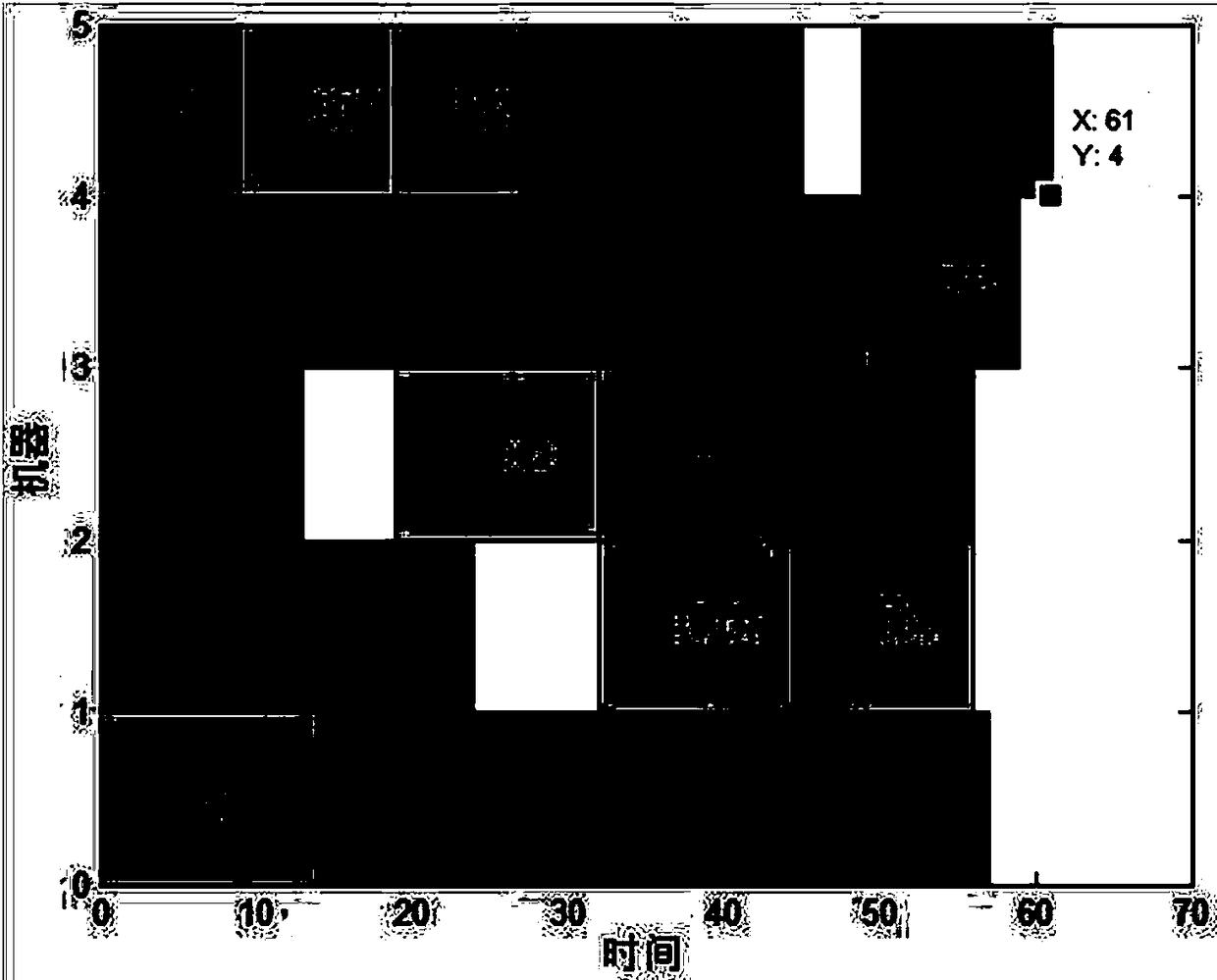

[0084] Embodiment two, on the basis of embodiment one, in order to provide a better embodiment, the main parameter of genetic algorithm is set as follows: population size P=40, crossover probability P c =0.8, mutation probability P m = 0.6, the maximum genetic algebra G is 200 generations.

Embodiment 3

[0085] Embodiment three, on the basis of embodiment one,

[0086] The initialization method of FJSP:

[0087] When the genetic algorithm is used to solve the target problem, the quality of the initial solution directly affects the solution quality of the algorithm and the convergence speed of the solution. Because FJSP not only needs to solve the problem of machine selection, but also needs to solve the problem of sequence of processing procedures. Aiming at the characteristics of FJSP, the machine selection part in the chromosome of the present invention adopts an integer random initialization method, that is, the number on each gene position on the chromosome indicates that the processing procedure is randomly generated in the sequence number of the optional machine set. The specific execution steps are as follows:

[0088] 1) In the optional workpiece set, select the first workpiece, and select the first process of the current workpiece;

[0089] 2) Randomly select a mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com