Solar cell sorter

A solar cell and sorting machine technology, applied in sorting and other directions, can solve problems such as complex structure, low efficiency, and large space occupied by rectangular tracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation and working principle of the solar cell sorting machine detection device proposed by the present invention will be described in detail below with reference to the drawings and preferred embodiments. Description.

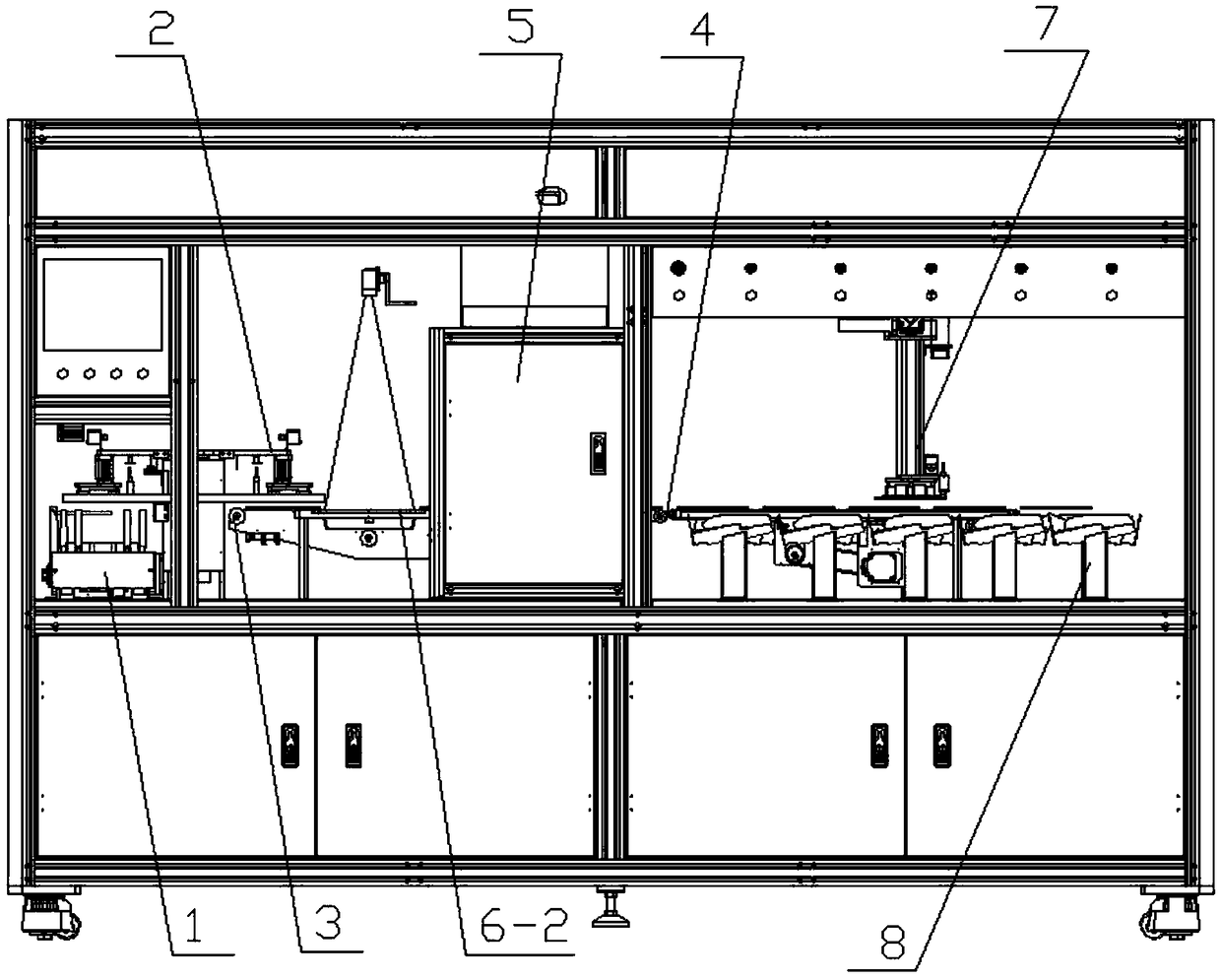

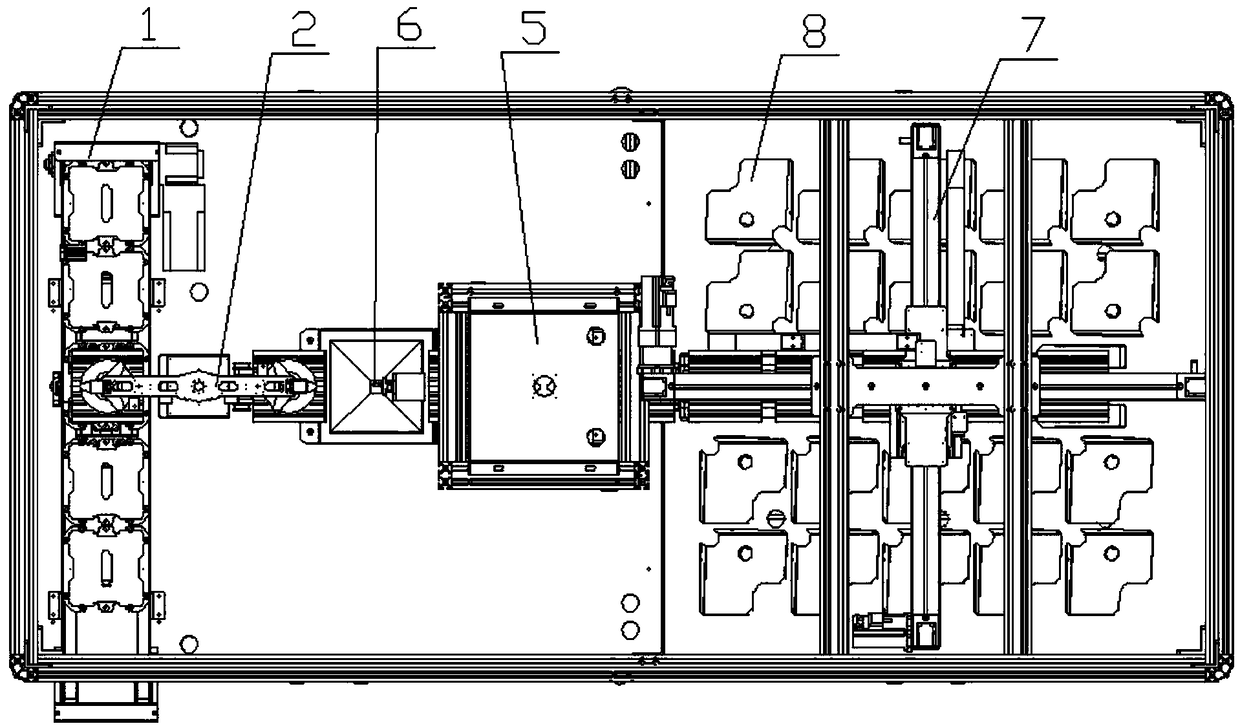

[0086] Such as figure 1 , figure 2 As shown, the solar cell sorting machine provided in this embodiment includes: a feeding device, a transmission device, a detection device, and a sorting device.

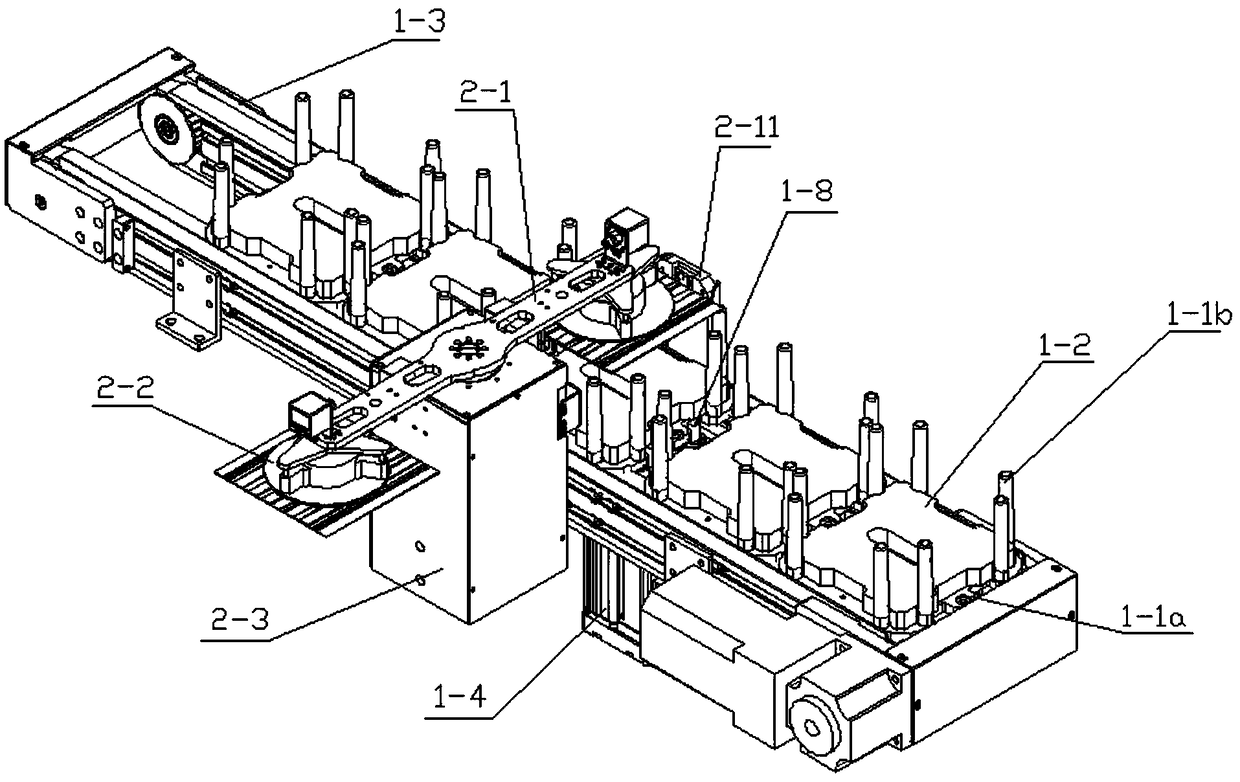

[0087] For the specific structure of the feeding device used in this embodiment, refer to Figure 3 to Figure 7 . Such as image 3 As shown, the feeding device includes: a magazine conveying module 1 and a rotary reclaiming module 2. reference Figure 7 It can be seen that the rotating reclaiming module 2 includes: a rotating arm 2-1, a vacuum suction cup 2-2, a power mechanism, a rotation angle monitoring m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com