Knitter for circular knitting machine

A technology of circular knitting machine and knitting machine, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of affecting the tightness of knitted fabrics, unable to adjust the angle and height of the yarn drum, unable to adjust the height of the hanging rack, etc. To achieve the effect of tightness and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

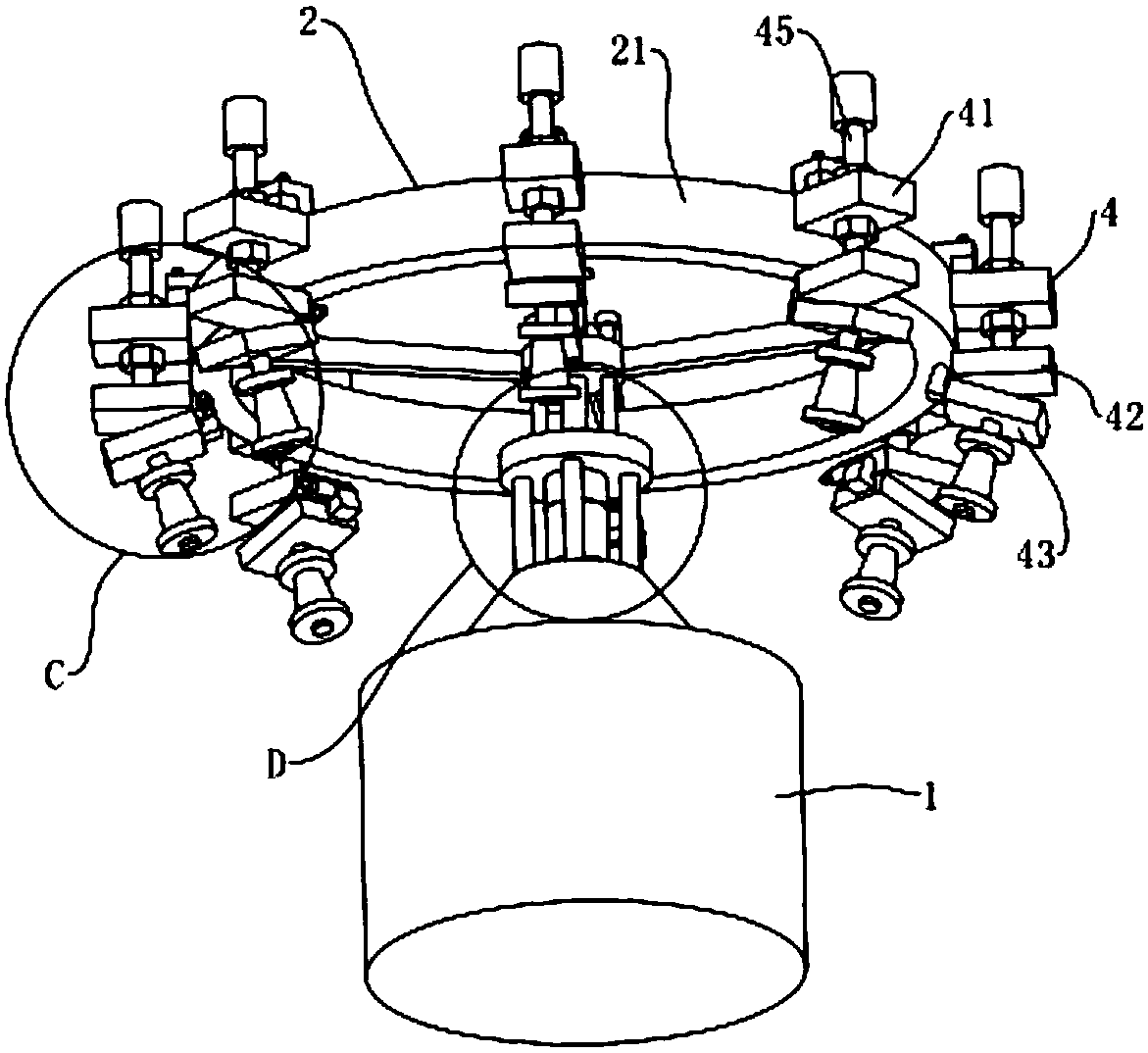

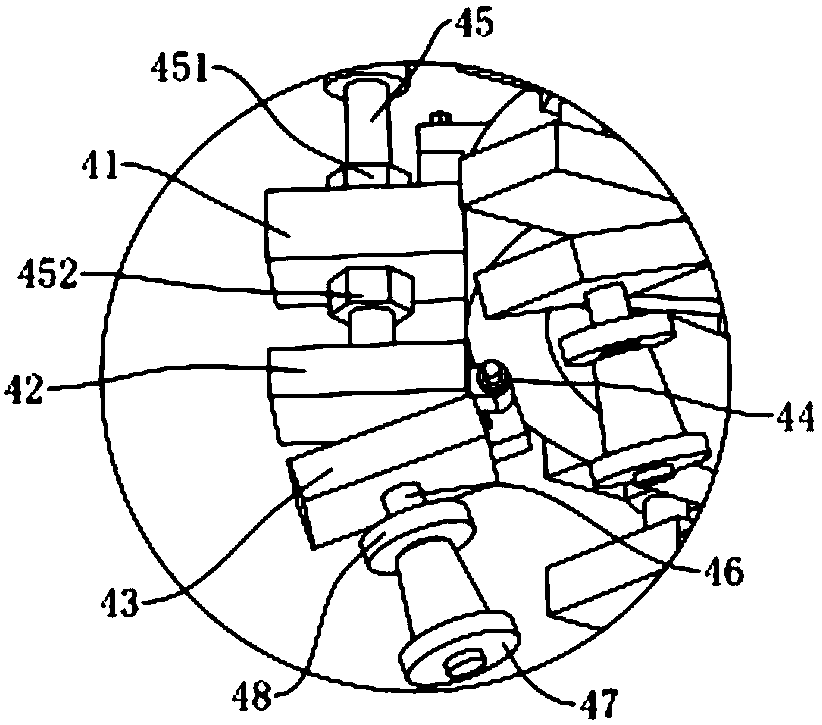

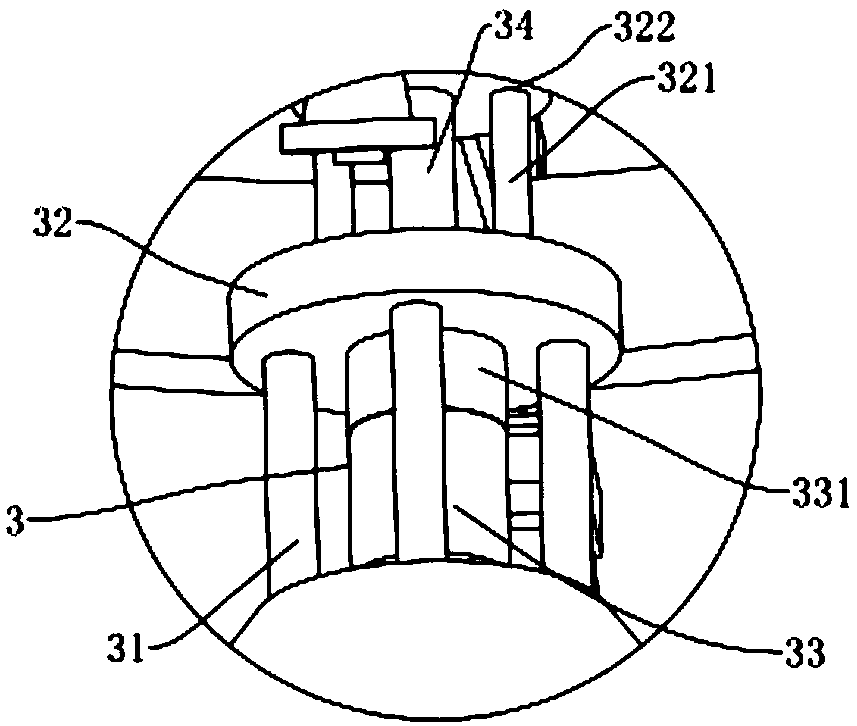

[0035] like Figure 1 to Figure 7 As shown, a knitting machine for a circular knitting machine includes a knitting machine body 1 and a material hanging frame 2 arranged above the knitting machine body 1, wherein the knitting machine body 1 is an ordinary double-sided large circular knitting machine, wherein the material hanging The frame 2 includes a material hanging ring 21, a connecting rod 22 and a disc 23. The material hanging ring 21 and the disc 23 are fixed by four connecting rods 22. A driving part 3 is arranged above the knitting machine body 1, wherein the driving part 3 Drive the material hanging frame 2 to adjust the height, and at the same time, eight groups of locking parts 5 are disassembled and connected to the material hanging frame 2. Eight yarn hanging parts 4 are connected, wherein the yarn tubes hung in the yarn hanging parts 4 are placed on the yarn hanging part 4. The height and angle of the part 4 can be adjusted. When it is necessary to adjust the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com