A precise heating system and method for an electric boiler based on dual-pipe temperature adjustment

A heating system and double-pipe technology, which is applied in the field of electric boiler heating, can solve the problems of insufficient utilization of heat energy, waste of heat energy, unfavorable utilization rate of heat energy, etc., and achieve the effect of realizing precise heating and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

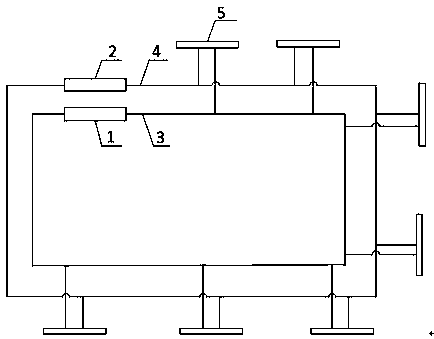

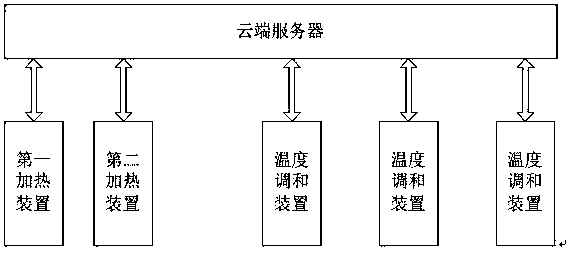

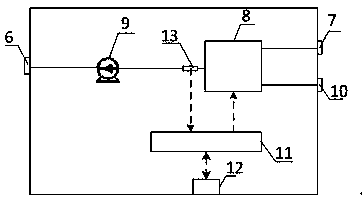

[0039] Such as Figure 1~2 As shown, a precise heating system for an electric boiler based on dual-pipe temperature reconciliation, including a cloud server, a first heating device 1, a second heating device 2, a first heating pipeline 3, a second heating pipeline 4, a cloud server and located in different Temperature regulating device 5 in the heating area;

[0040] The first heating pipeline 3 and the second heating pipeline 4 are arranged along each heating area, and the first heating pipeline 3 sequentially transports the hot water output by the first heating device 1 to each heating area, and transports the remaining hot water to each heating area. Back to the first heating device 1; the second heating pipeline 4 transports the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com