nail gun

A nailing gun and piston technology, applied in the field of nailing guns, can solve problems such as poor reliability and failure of firing pin locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present disclosure will be described below in conjunction with the accompanying drawings and embodiments. It should be understood that the embodiments described here are only used to explain the present disclosure, but not to limit the present disclosure. In addition, it should be noted that, for the convenience of description, only a part but not all structures related to the embodiments of the present disclosure are shown in the drawings. In the case of no conflict, the following embodiments and the features in the embodiments can be combined with each other.

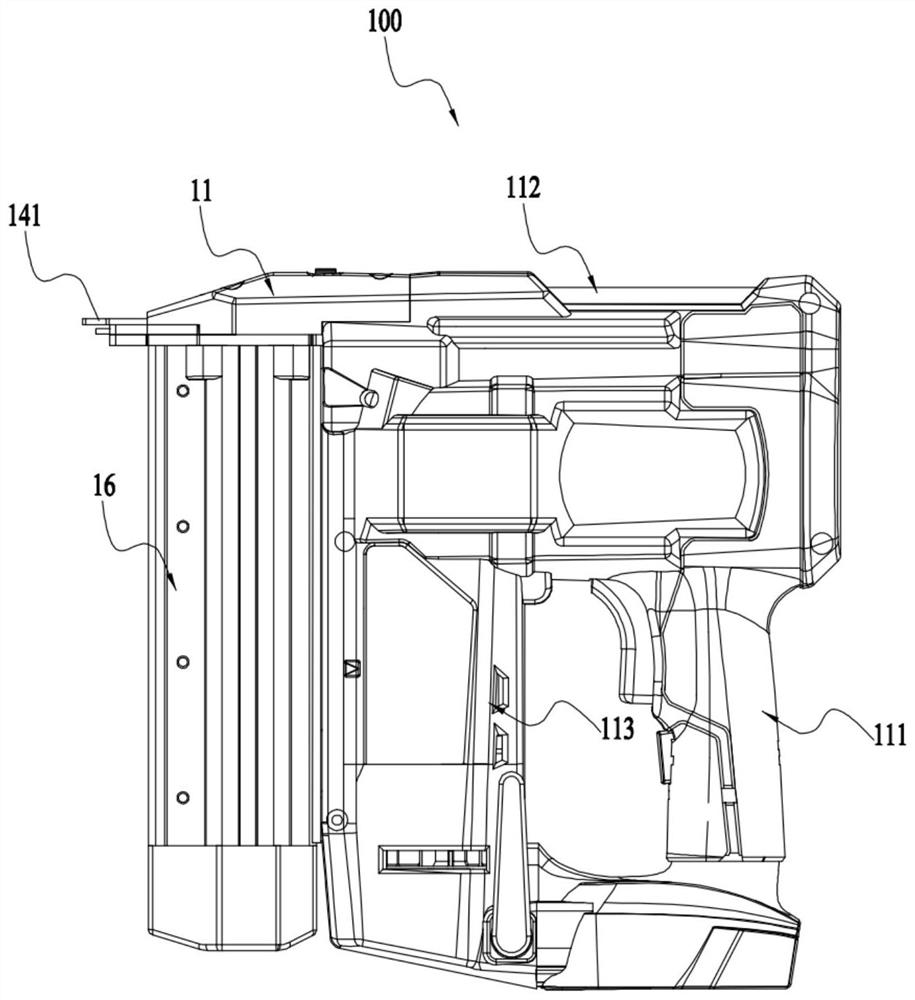

[0045] figure 1 A nail driving gun 100 according to a first embodiment of the present disclosure is shown, and the nail driving gun 100 is used to generate an impact force on a nail so that the impact nail is driven into a workpiece.

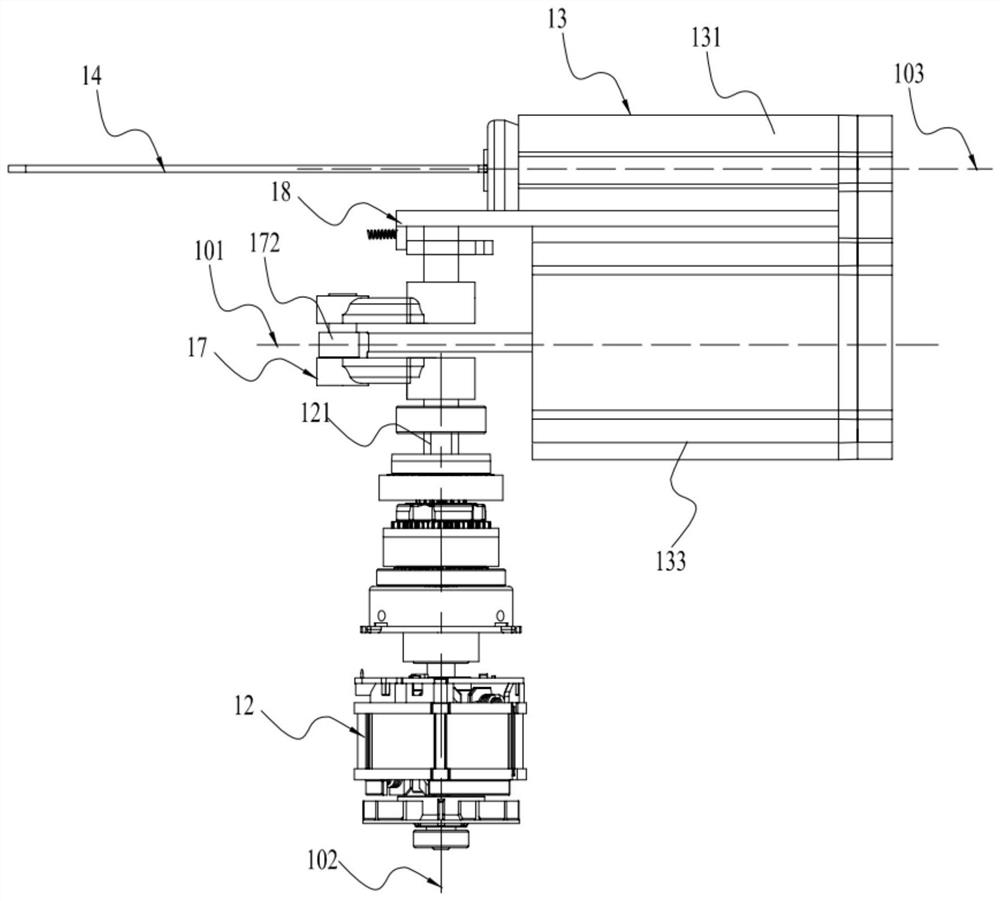

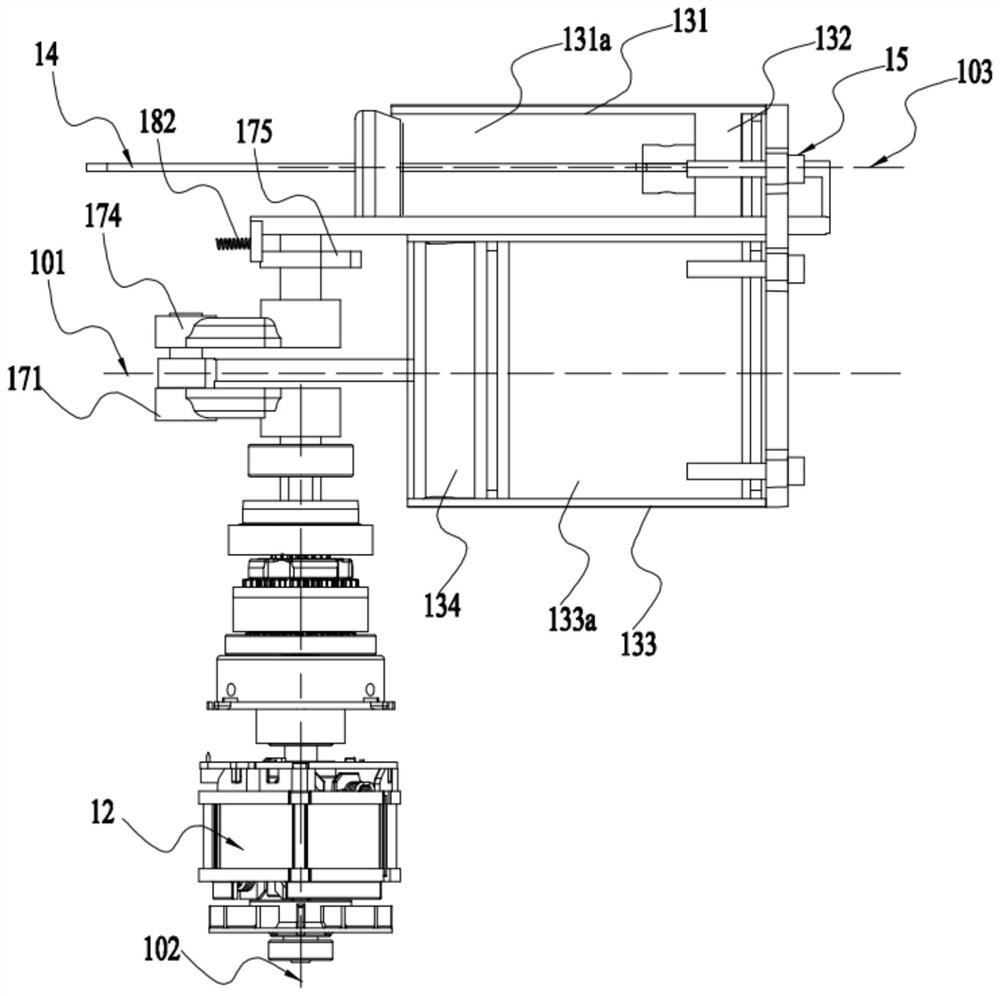

[0046] like Figure 1 to Figure 9As shown, the nailing gun 100 includes: a casing 11 , a prime mover 12 , an impact mechanism 13 , a striker 14 ,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap