Guardrail with optimized structural on construction machinery

A technology for construction machinery and guardrails, which is applied to the field of guardrails with optimized structures on construction machinery, can solve the problems of narrow space, inconvenient passage or operation, and low safety, and achieve the effect of increasing the passage size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

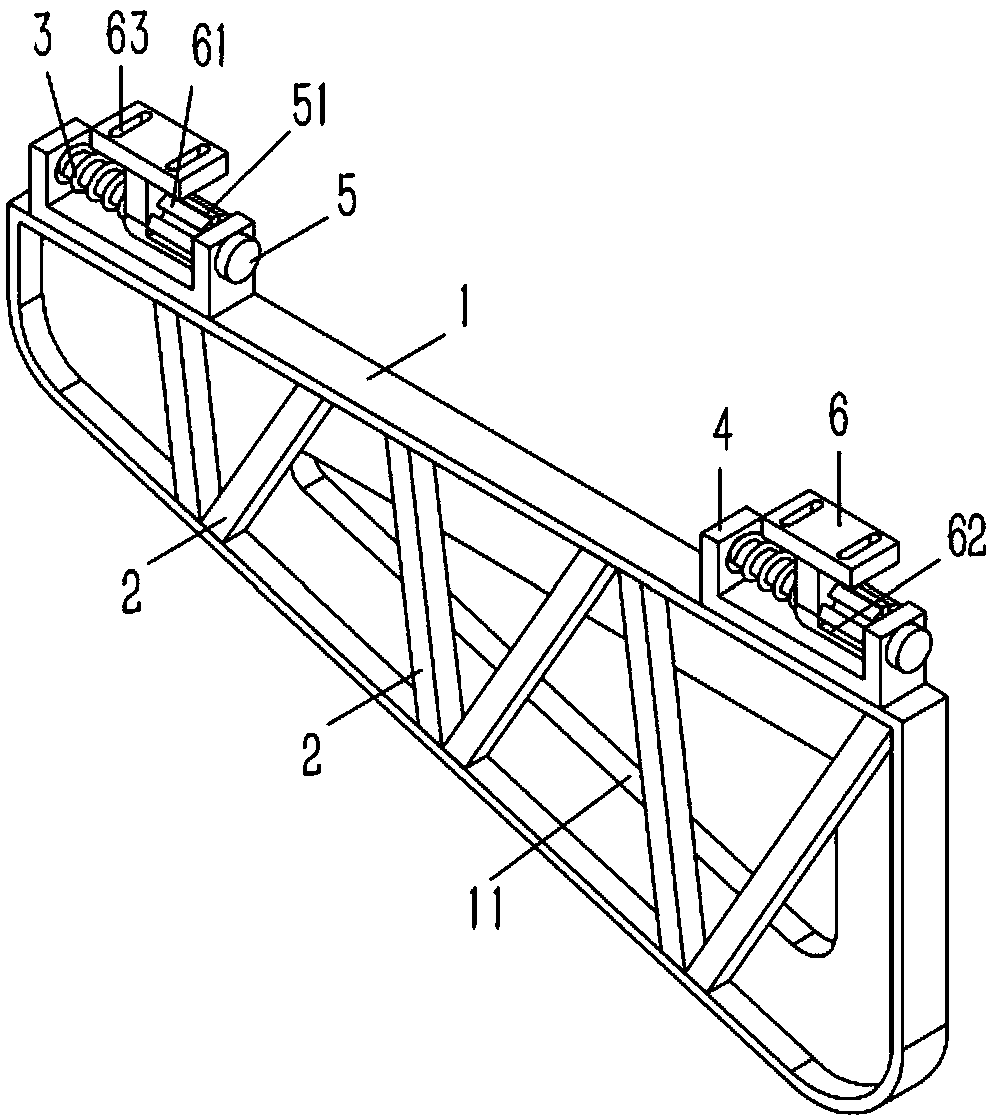

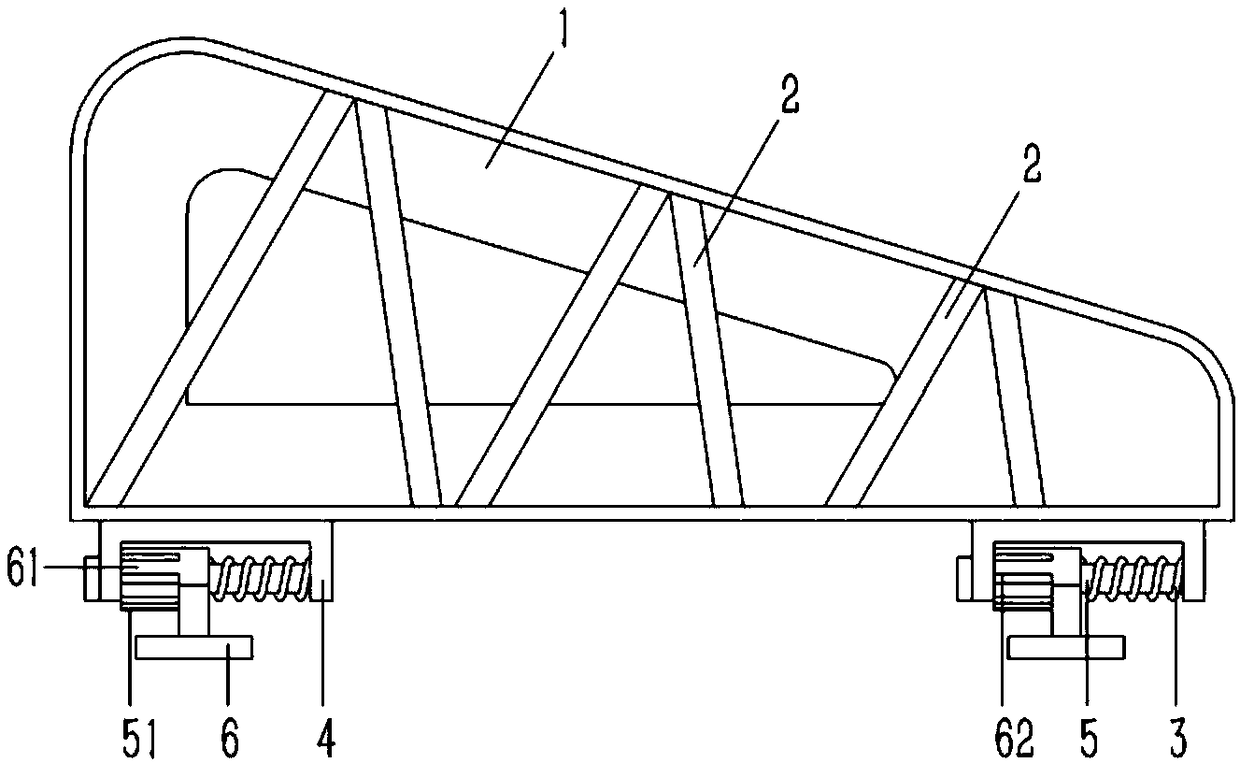

[0015] Example: see figure 1 , 2 As shown, a structure-optimized guardrail on construction machinery includes a guardrail 1, the periphery of the guardrail 1 is formed with flanging, and a number of inclined support railings 2 are fixed on the guardrail 1, and the two ends of the support railings 2 are fixed On the flanging, several flip positioning brackets are fixed on the flanging at the bottom of the slab 1, and the flip positioning bracket includes a connecting frame 4 in the shape of "冂", the connecting frame 4 is inserted and fixed with a rotating shaft 5, and the bottom of the connecting frame 4 The side is provided with a T-shaped fixed seat 6, the upper end of the fixed seat 6 is inserted on the rotating shaft 5, and one side of the upper end of the fixed seat 6 is formed with a shaft sleeve 61, and several roads are formed on the shaft sleeve 61 to penetrate the inner and outer walls of the shaft sleeve 61. Slot 62, a positioning plate 51 is formed on the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com