Textile drying device

A drying device and textile technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of inability to dry textiles and affect the drying efficiency of textiles, achieve strong practicability and applicability, and improve drying efficiency. The effect of dry efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

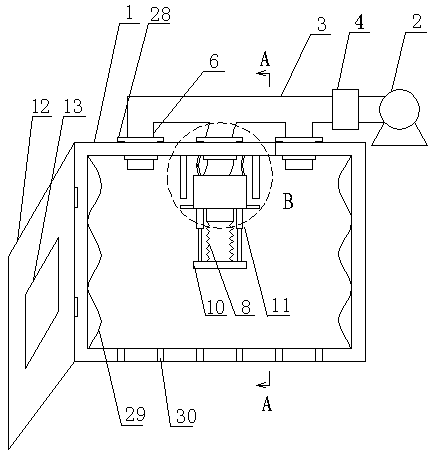

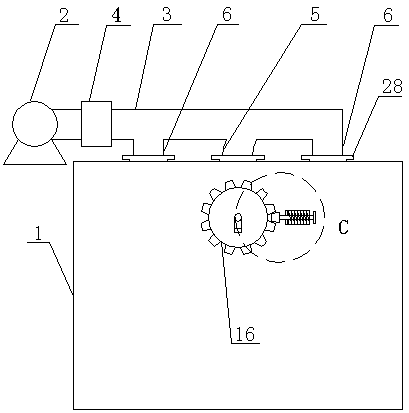

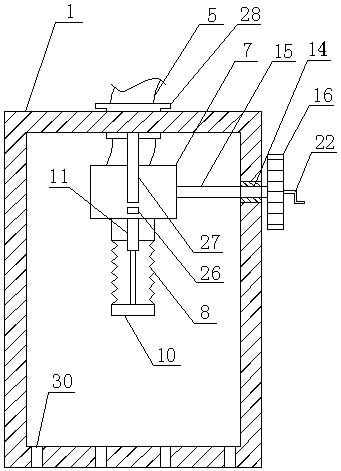

[0026] Such as Figure 1 to Figure 6 As shown, a textile drying device includes a box body 1, the upper end of the box body is provided with a fan 2, the fan is connected with a main air duct 3, and the main air duct is provided with an air heater 4, a second A pipe 5 and a second branch pipe 6, the first branch pipe and the second branch pipe are connected to the air inlet on the top of the box body, the first branch pipe passes through the air inlet port and extends to the inside of the box body until it passes through the air inlet located in the box body The support base 7, and the bottom end of the first branch pipe is connected with a bellows 8, the outer circumference of the bottom end of the bellows is fixed on the fixed plate 10 with the air outlet 9, and a telescopic cylinder is arranged between the support base and the fixed plate 11. The support seat and the box body are flexibly connected through the angle adjustment mechanism arranged on the back of the box body....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com