Anti-blocking sewer pipeline

An anti-clogging and pipeline technology, applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., can solve the problems of pipeline scaling, difficult to clean, affecting sewage discharge, etc., to achieve smooth recovery of filters and pipelines, and scientific design. Reasonable and structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

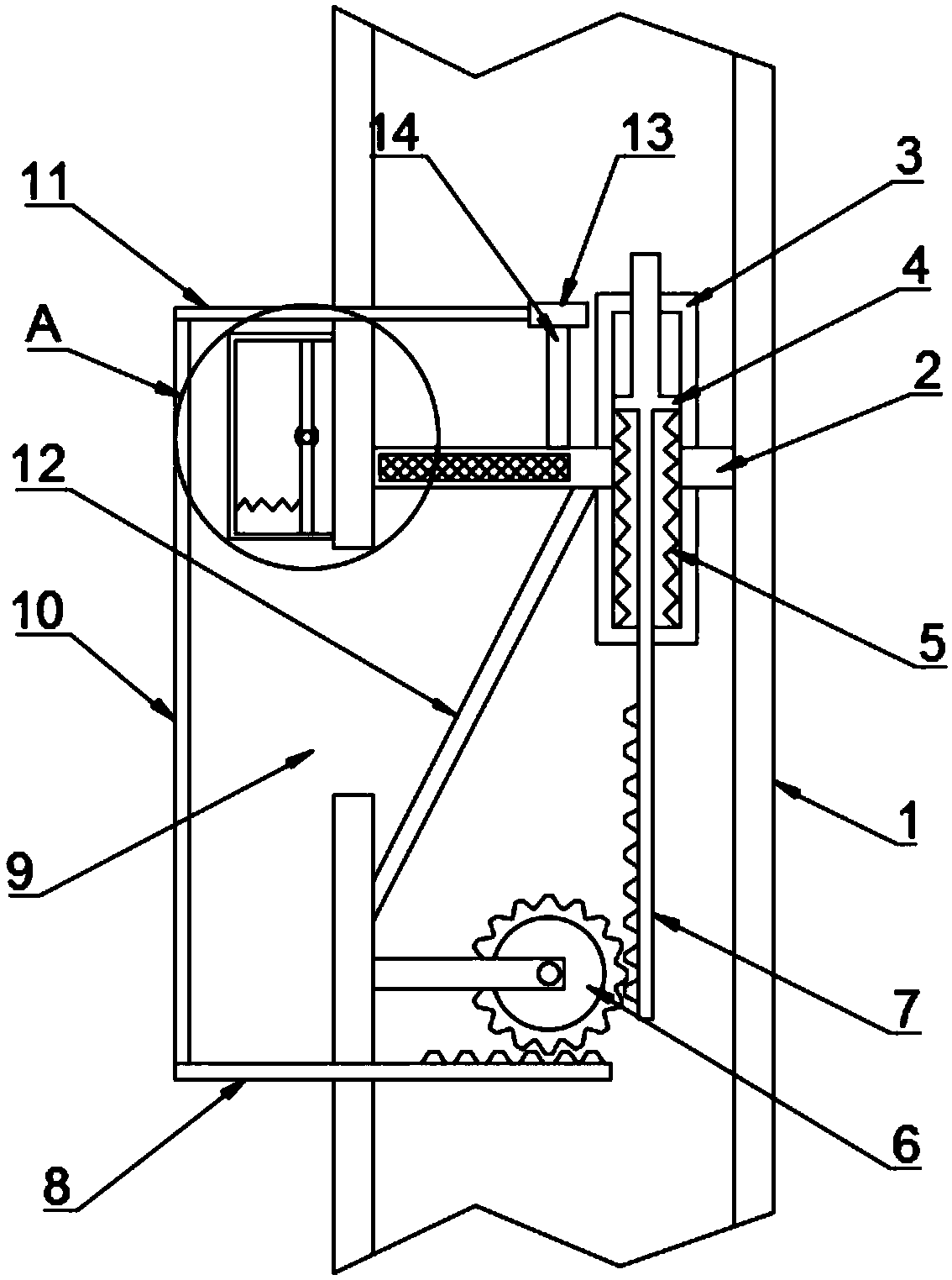

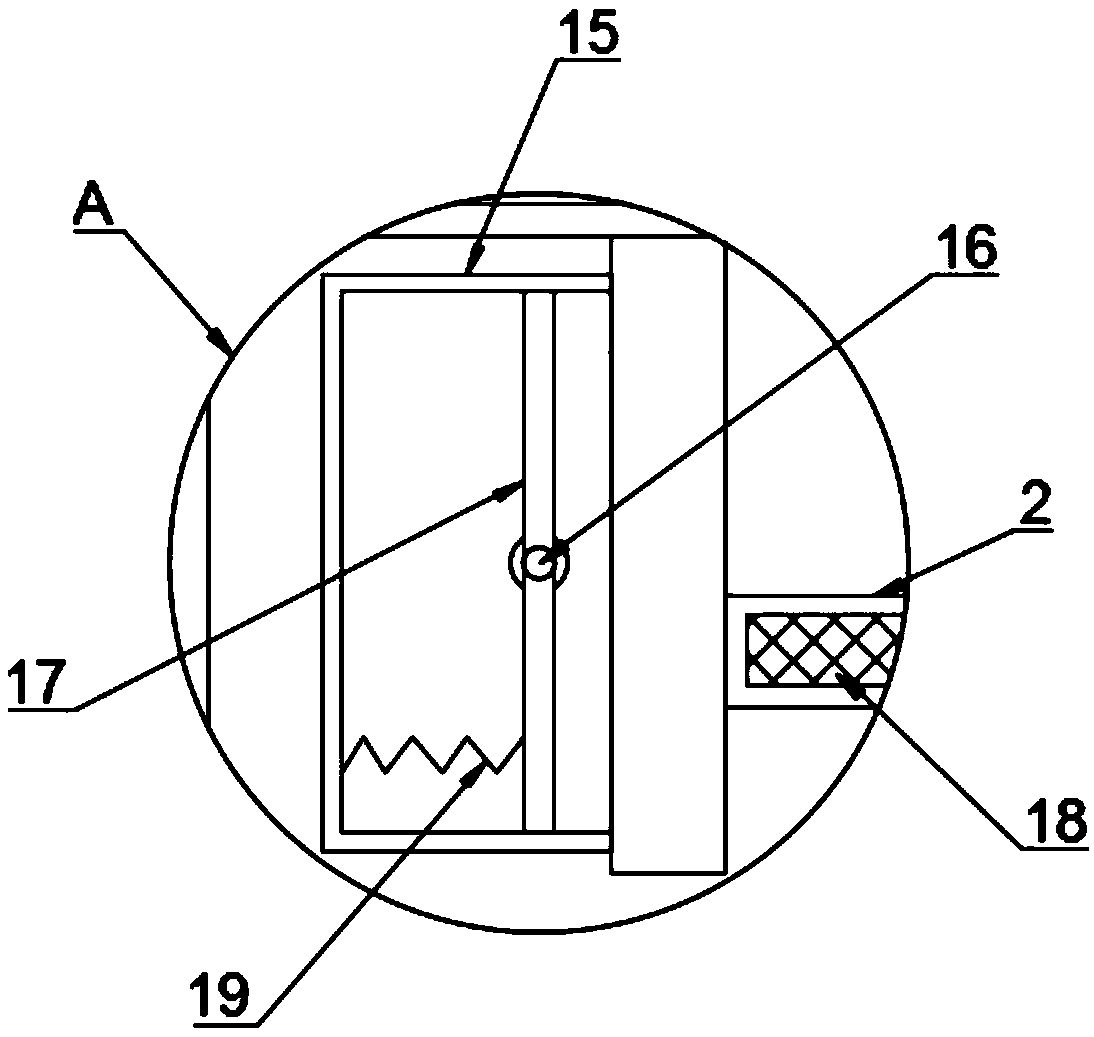

[0024] refer to Figure 1-2 , an anti-clogging sewer pipe, comprising a pipe 1, an installation plate 2 is fixed on the inner wall of the pipe 1, a first installation port and a second installation port are opened on the installation plate 2, a fixed pipe 3 is installed in the first installation port, the second A filter screen 18 is installed in the installation port, and a slide bar 7 slides in the fixed tube 3, and the outer wall of one end of the slide bar 7 located in the fixed tube 3 is provided with a flange 4, which is fixed between the flange 4 and the inner bottom wall of the fixed tube 3 A return spring 5 is connected, and the return spring 5 is set to ensure that the slide bar 7 can return to its original position under the reverse elastic force of the return spring 5 after it moves down. Extending to the outside of the fixed pipe 3, a mounting plate is fixed on the inner wall of the pipe 1, a gear 6 is installed on the end of the mounting plate away from the inner...

Embodiment 2

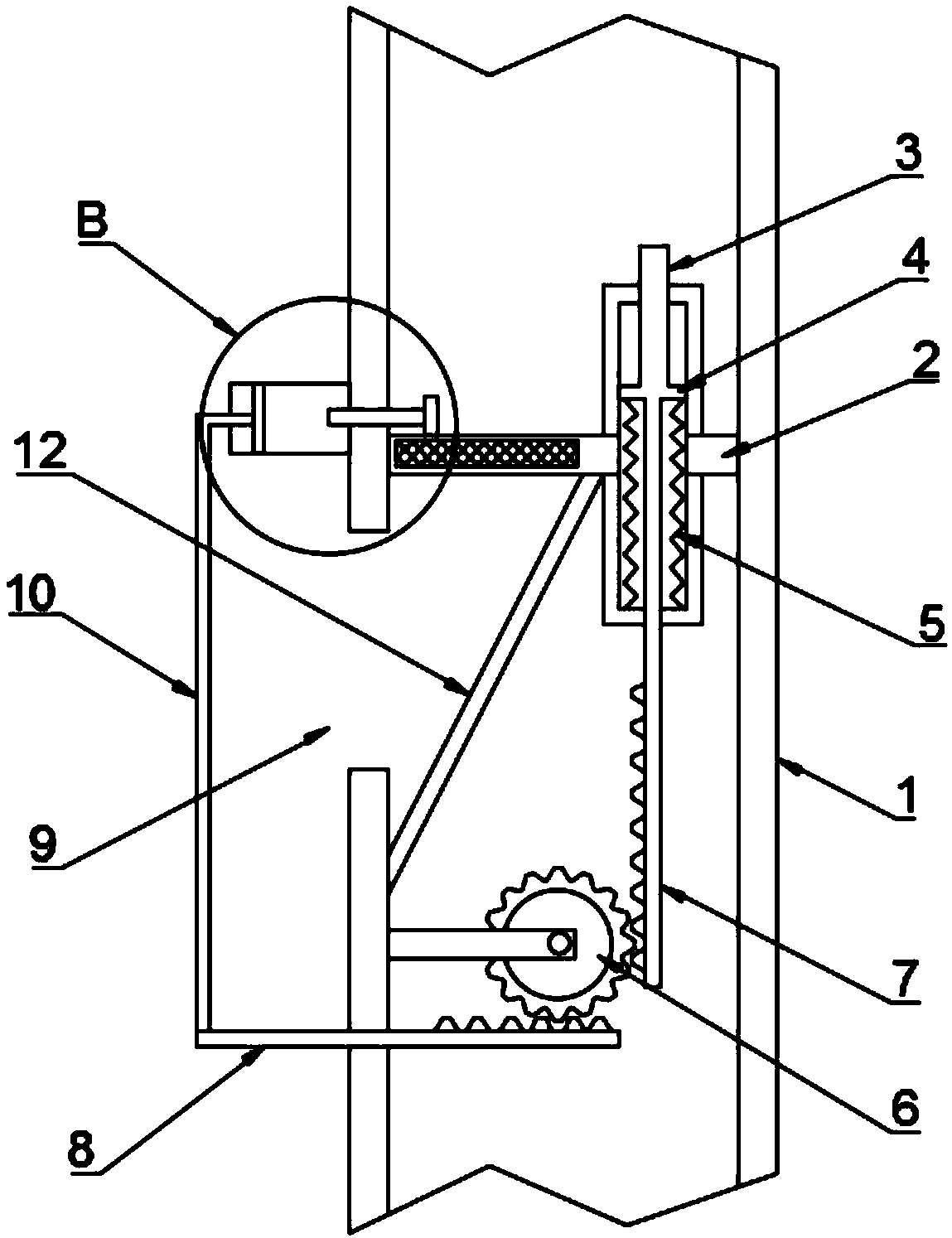

[0029] refer to Figure 3-4 , the difference from Embodiment 1 is that the cleaning mechanism includes a first moving rod 8 inserted in parallel on the outer wall of the pipeline 1, the first moving rod 8 is located on one side of the gear 6 and is arranged perpendicular to the sliding rod 7, the second A side wall of a moving bar 8 near the gear 6 is provided with a second sawtooth meshed with the gear 6, the outer wall of the pipeline 1 is fixed with an air bag 20, and the air bag 20 is slidably connected with a push plate 21, and the push plate 21 is connected to the first The moving rods 8 are connected by connecting rods 10. An air outlet pipe 22 is inserted in the airbag 20. The end of the air outlet pipe 22 away from the airbag 20 runs through the outer wall of the pipeline 1 and extends to the side of the filter screen 18 away from the gear 6. When the filter screen 18 When it is blocked, the water in the pipe 1 accumulates, the water pressure increases, and the slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com