Method for installing spatial-bending-joint discontinuous tubular truss

An installation method and continuous tube technology, applied to truss structures, truss beams, joists, etc., can solve the problems of low installation precision, high construction cost, and low efficiency, and achieve the effect of improving installation efficiency and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

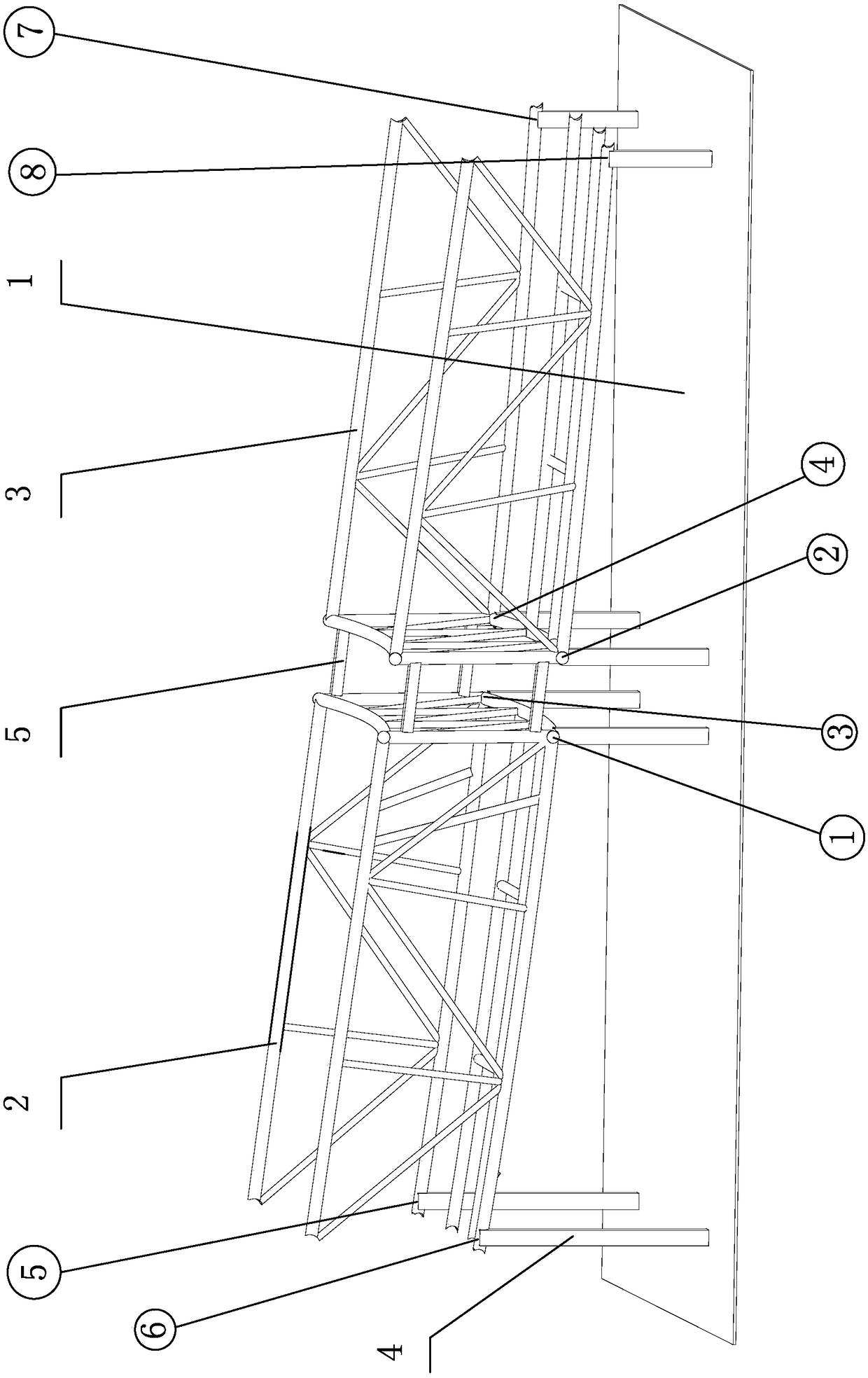

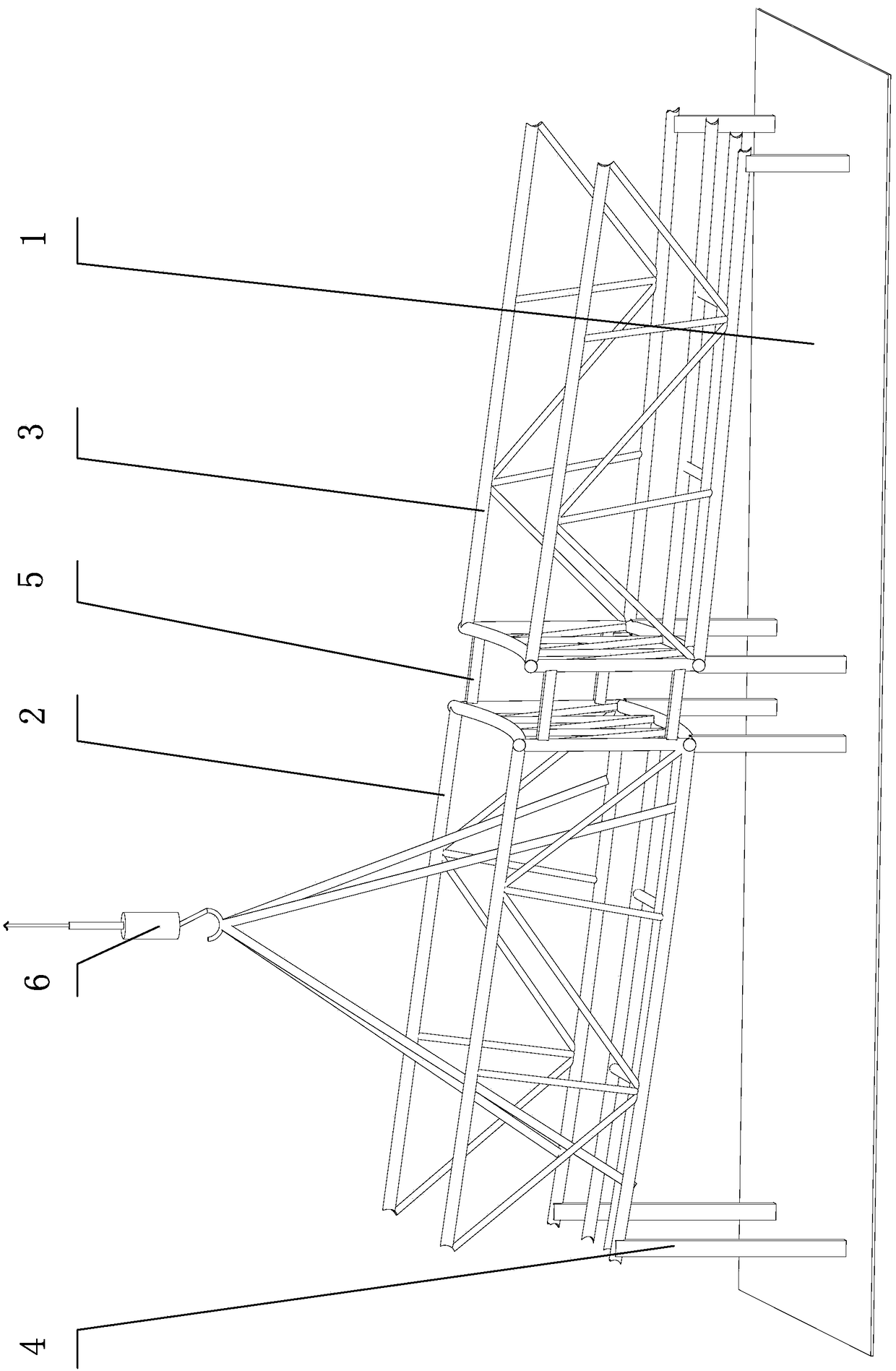

[0019] The technical solution of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings (the front and rear pipe trusses 2, 3 are two discontinuous pipe trusses).

[0020] The installation method of the space bend discontinuous pipe truss of the present invention, its operating steps are:

[0021] 1. Level the site of the construction site, lay steel plates with a thickness of more than 10mm to build the assembly platform 1, adjust the uneven parts, and check the levelness of the assembly platform 1 with a level, so that the unevenness of the assembly platform 1 is ≦ 2mm.

[0022] 2. Calculate the spatial coordinate values of 8 nodes ①, ②, ③, ④, ⑤, ⑥, ⑦, ⑧ on the front pipe truss 2 and the rear pipe truss 3, among which: nodes ①, ②, ③, ④ are the front , the relative left and right endpoints of the bottom of the rear pipe truss 2 and 3, the nodes ⑤ and ⑥ are the left and right breakpoints at the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com