An automobile composite envelope terminal

A technology for covering wires and automobiles, applied in the direction of clamping/spring connection, contact parts, etc., which can solve the problems of insufficient reliability, unreliable insertion of male and female ends, and complicated fixing of terminals and automobiles, so as to achieve stable connection and coordination. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

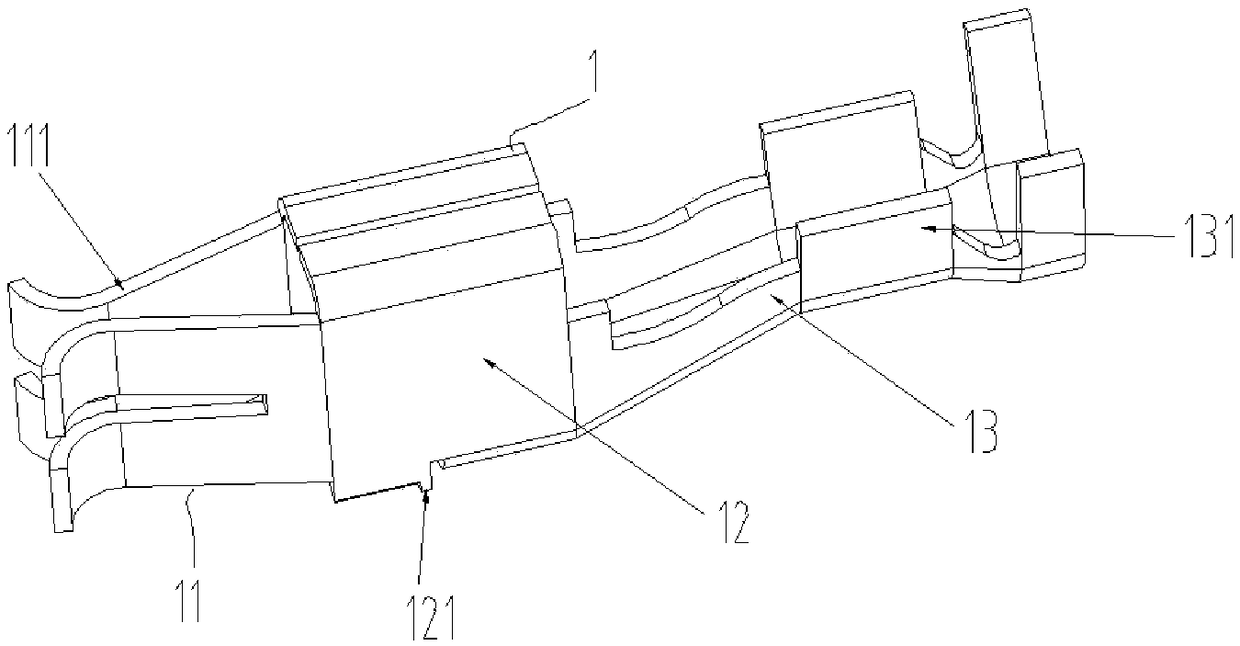

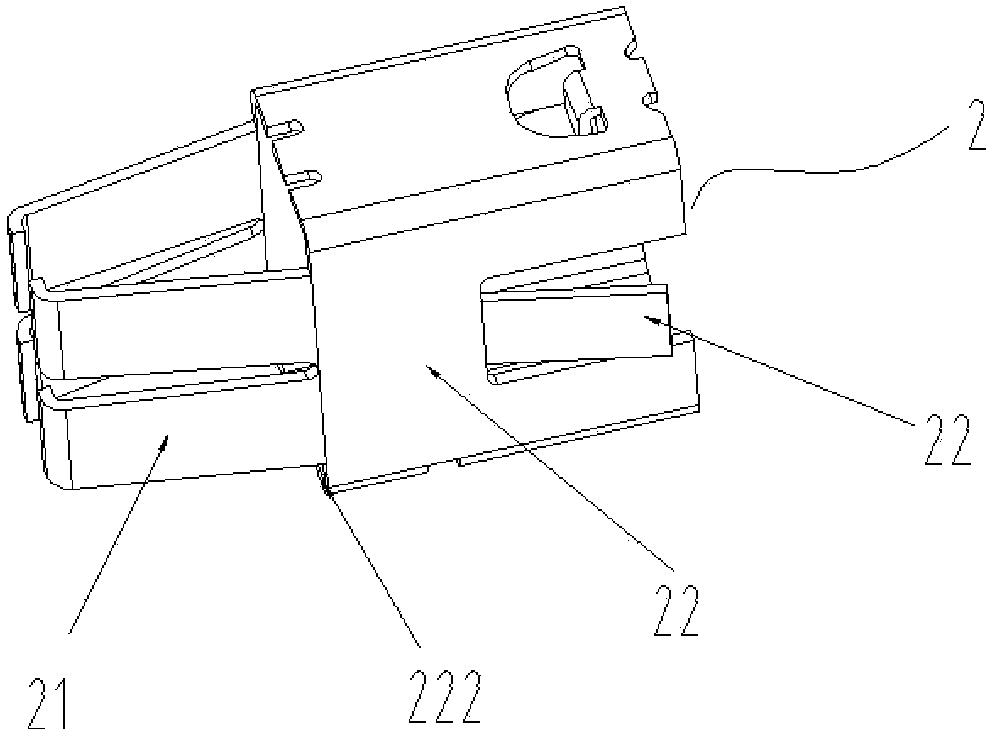

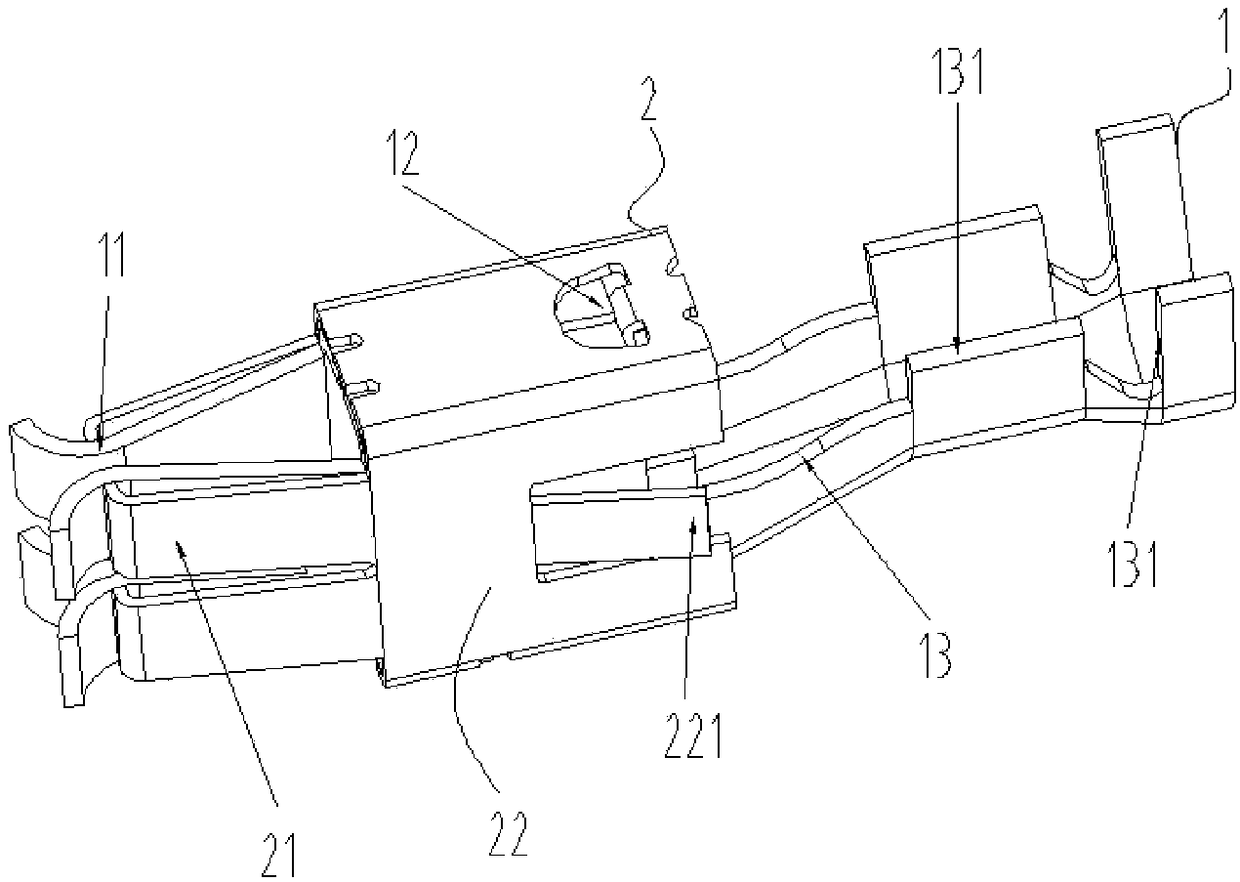

[0026] An automobile composite covered wire terminal, the covered wire terminal is fixedly connected to the plastic fixing plate of the car, the covered wire terminal includes a male end and a female end, and the female end includes a plug-in part 1 and a socket set in the middle of the outside of the plug-in part 1 In the fixed part 2, one end of the plug-in part 1 is provided with a plurality of plug-in ports 11, and each plug-in port 11 includes two opposite pressing pieces 111, and the other end of the plug-in part 1 is provided with a bendable The crimping sheet 14, one end of the fixing part 2 is provided with a crimping strip 21 for compressing the two pressing pieces 111, and the other end of the fixing part 2 is provided with a clipping strip 221 for clamping on the plastic fixing plate, such as figure 1 , figure 2 shown.

[0027] The structure of the socket part 1 is as follows figure 1 As shown, it includes two sockets 11 at one end, a rectangular connecting port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com