Inter-board connector and socket thereof

A technology of board-to-board connectors and sockets, which is applied in the direction of connection, contact parts, base/housing, etc., can solve the problems of material waste and high cost, and achieve the effects of saving metal materials, high production efficiency, and avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

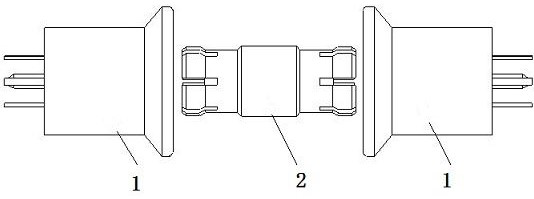

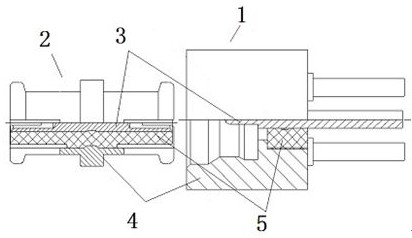

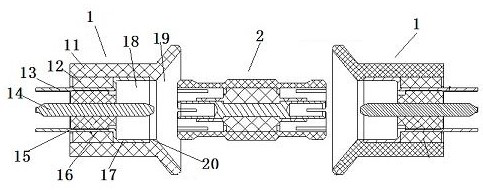

[0037] First embodiment of the plate connectors of the present invention, such as Figure 3 to 4 As shown, the plate connectors include two sockets 1 disposed on two respective panels (not shown), but also include between the two sockets 1 for adaptation. The plug-in adapter 2, the socket is inserted at its front end.

[0038] The socket 1 includes an inner conductor 14 extending in the front-rear direction, and an insulating support 15 is provided around the outer peripheral surface of the inner conductor 14, and an outer casing 11 is disposed outside the insulating support 15, and the outer casing 11 is composed of composite plastic, and the outer casing 11 An intermediate conductor 13 is provided in the annular space between the insulating support 15, the intermediate conductor 13 is a cylindrical metal layer structure formed by the copper strip, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com