Universal wheel mechanism with double parallel rotating shafts

A rotary axis, double-parallel technology, applied in the directions of casters, wheels, transportation and packaging, can solve problems such as equipment yaw, and achieve the effect of ensuring driving stability and driving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

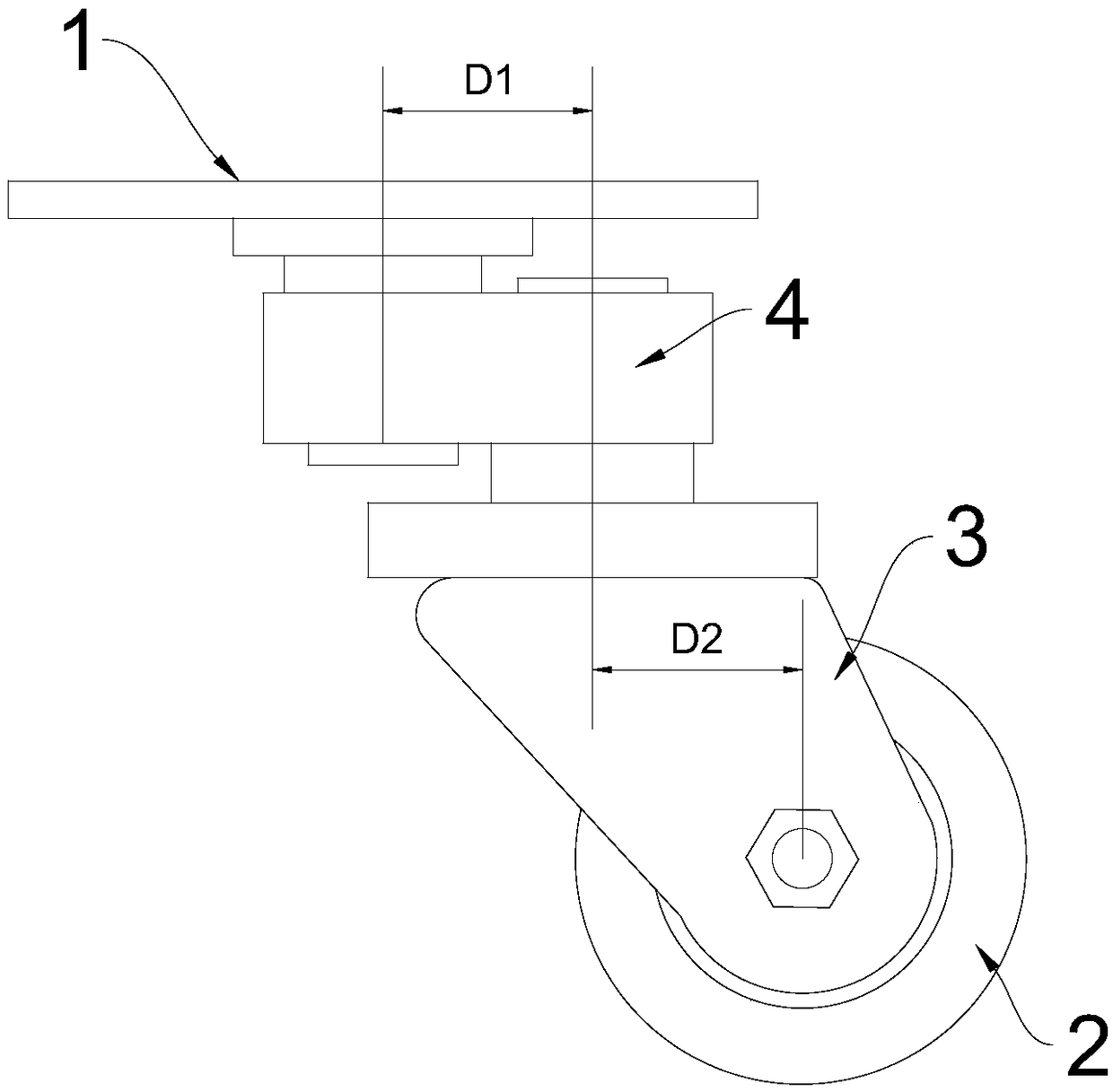

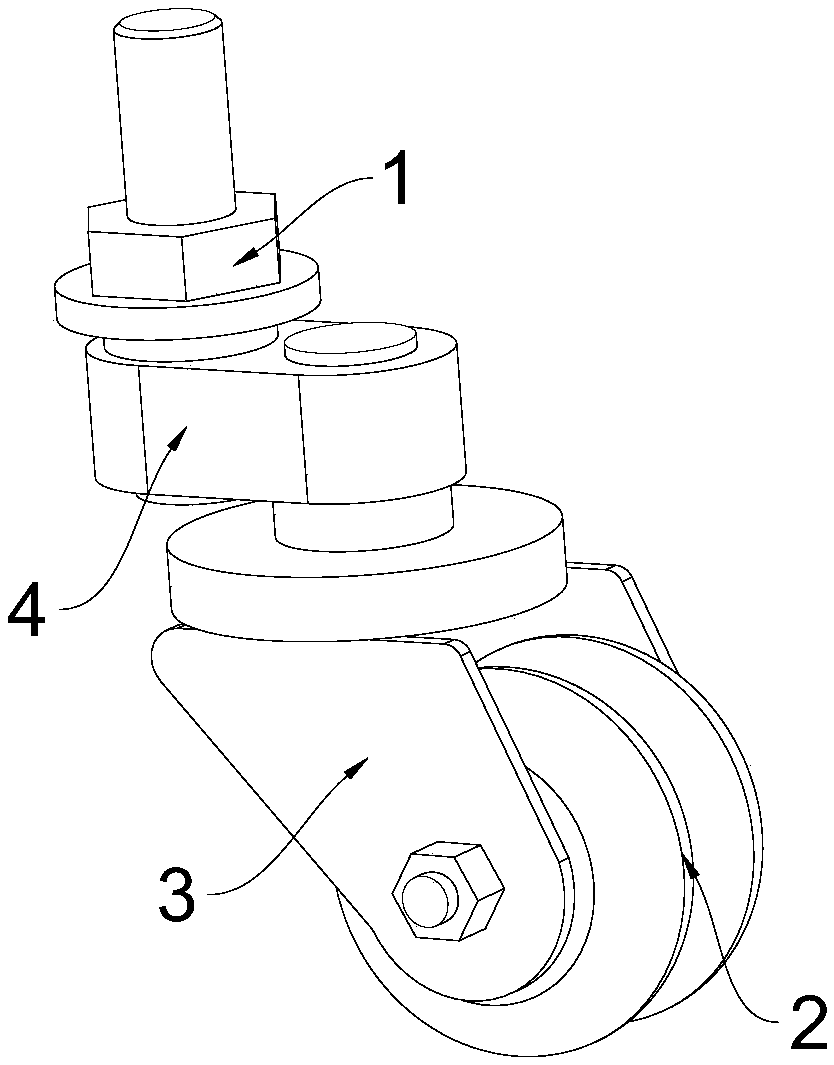

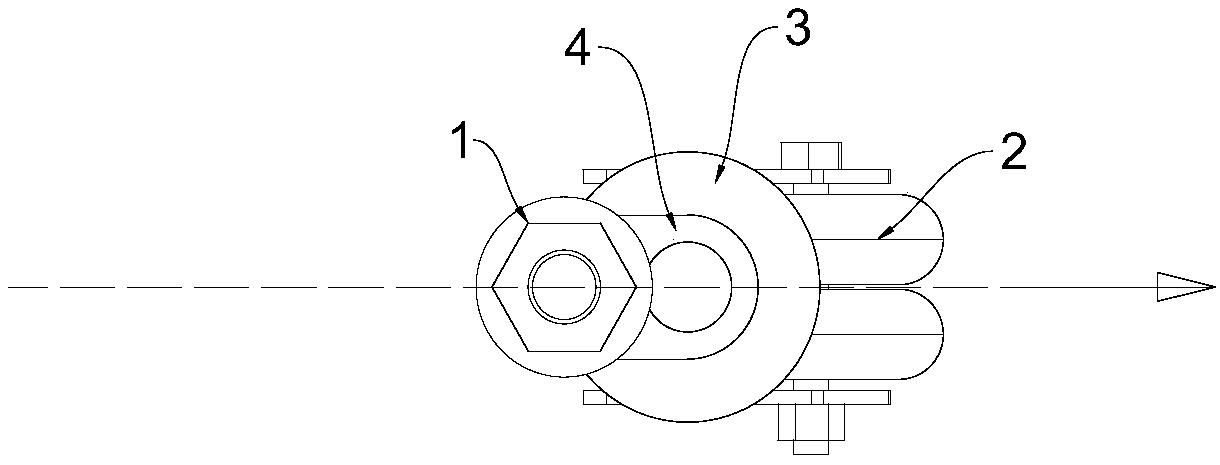

[0020] as attached figure 1 The shown universal wheel mechanism with double parallel shafts includes a wheel base 1, a wheel body 2, a wheel bracket 3 and a transition piece 4; the wheel bracket 3 is installed on the wheel base 1 through the transition piece 4, and the wheel The bracket 3 and the transition piece 4 form a first rotation pair, the transition piece 4 and the wheel seat 1 form a second rotation pair, the rotation axes of the first rotation pair and the second rotation pair are parallel to each other, and the distance between the two rotation axes is an eccentricity (such as figure 1 in D1); the wheel body 2 is rotatably mounted on the wheel bracket 3, and it is eccentrically installed relative to the wheel bracket 3, and its rotation center is offset from the shaft of the first rotating pair, and the offset distance is The second eccentricity (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com