Pneumatic tire manufacturing method and pneumatic tire

一种充气轮胎、制造方法的技术,应用在轮胎胎面/胎面花纹、轮胎零部件、胎等方向,能够解决高负载区域驾驶稳定性能下降、性能的改善效果不充分等问题,达到提高驾驶稳定性能、刚性提高、衰减性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

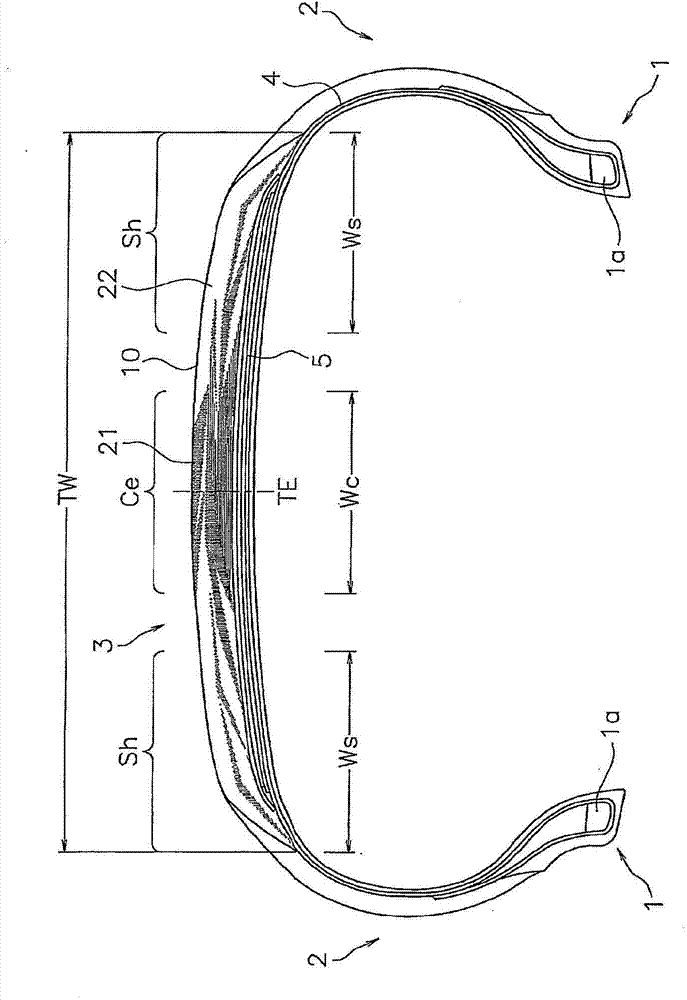

[0057] figure 1 The illustrated pneumatic tire includes: a pair of bead portions 1; sidewall portions 2 extending outward in the tire radial direction from the respective bead portions 1; end connection. A reinforcing material such as a belt layer 5 is disposed on the outer periphery of the carcass layer 4 formed in a ring shape, and a tread rubber 10 is provided to cover the reinforcing material. Although not shown, the outer peripheral surface of the tread rubber 10 is provided with: grooves such as longitudinal grooves or horizontal grooves; conditions corresponding to the tread pattern.

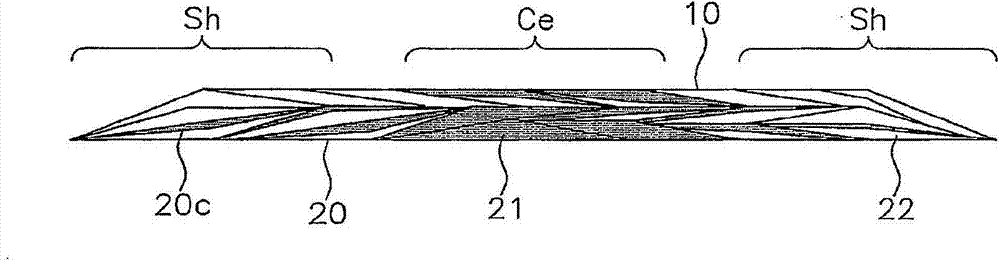

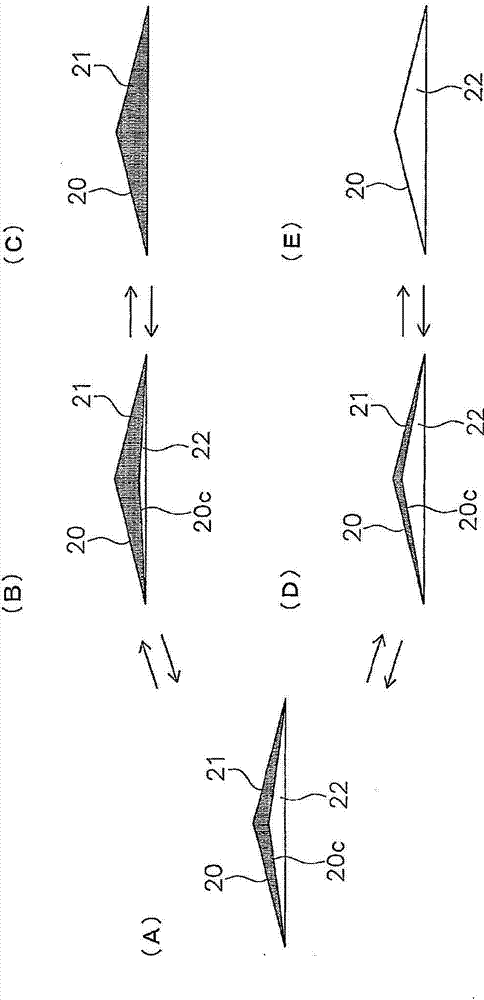

[0058] The tread rubber 10 is composed of a rubber belt wound body formed by helically winding a rubber belt, and is formed by a belt winding method described later. In this tread rubber 10, in the center region Ce (corresponding to the first region) located at the central part in the tread width direction and the shoulder regions Sh (corresponding to the second region) at the end par...

no. 2 approach

[0081] Since the second embodiment is the same as the first embodiment except for the items described below, common points will be omitted and differences will be mainly described. The same reference numerals are assigned to the same components or parts as those described in the first embodiment, and repeated descriptions will be omitted.

[0082] Image 6 It is a view showing the tread rubber 11 before vulcanization, and schematically depicts a cross section of the rubber belt 20 constituting the rubber belt wound body. In this tread rubber 11, an inner region In (corresponding to the first region) located on one side in the tread width direction which becomes the vehicle inner side when the vehicle is mounted, and the other side in the tread width direction which becomes the vehicle outer side when the vehicle is mounted. The outer area Out (corresponding to the second area) on one side is mainly equipped with different rubber. That is, the rubber 21 (corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com