Drilling machine metal chip recycling device

A recycling device and metal shavings technology, applied in the direction of metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of increasing the floor area of the drilling machine, affecting the safety of the factory, and easily damaging the guide rail, etc., to ensure cooling effect, high practical value, and the effect of preventing metal shavings from being difficult to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the technical solutions of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

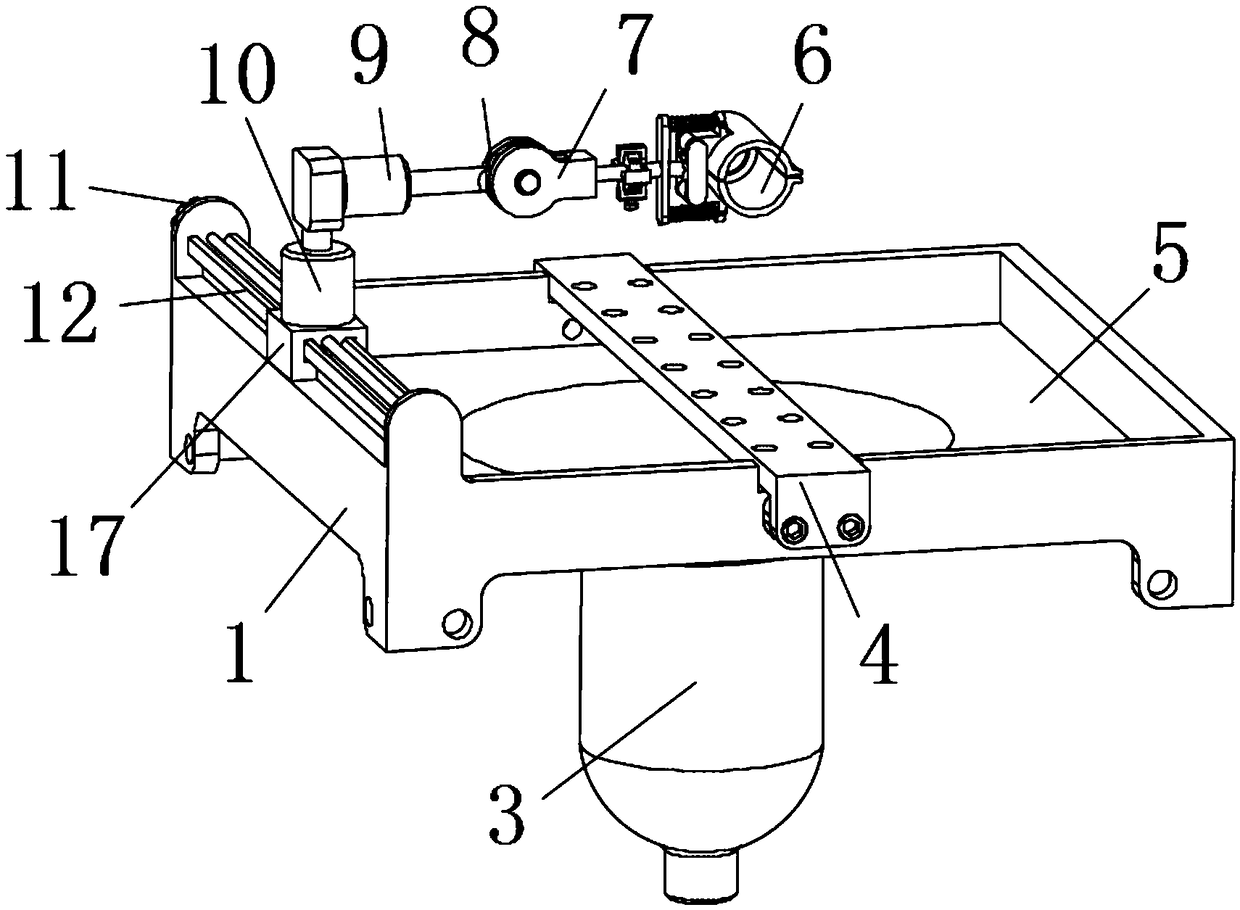

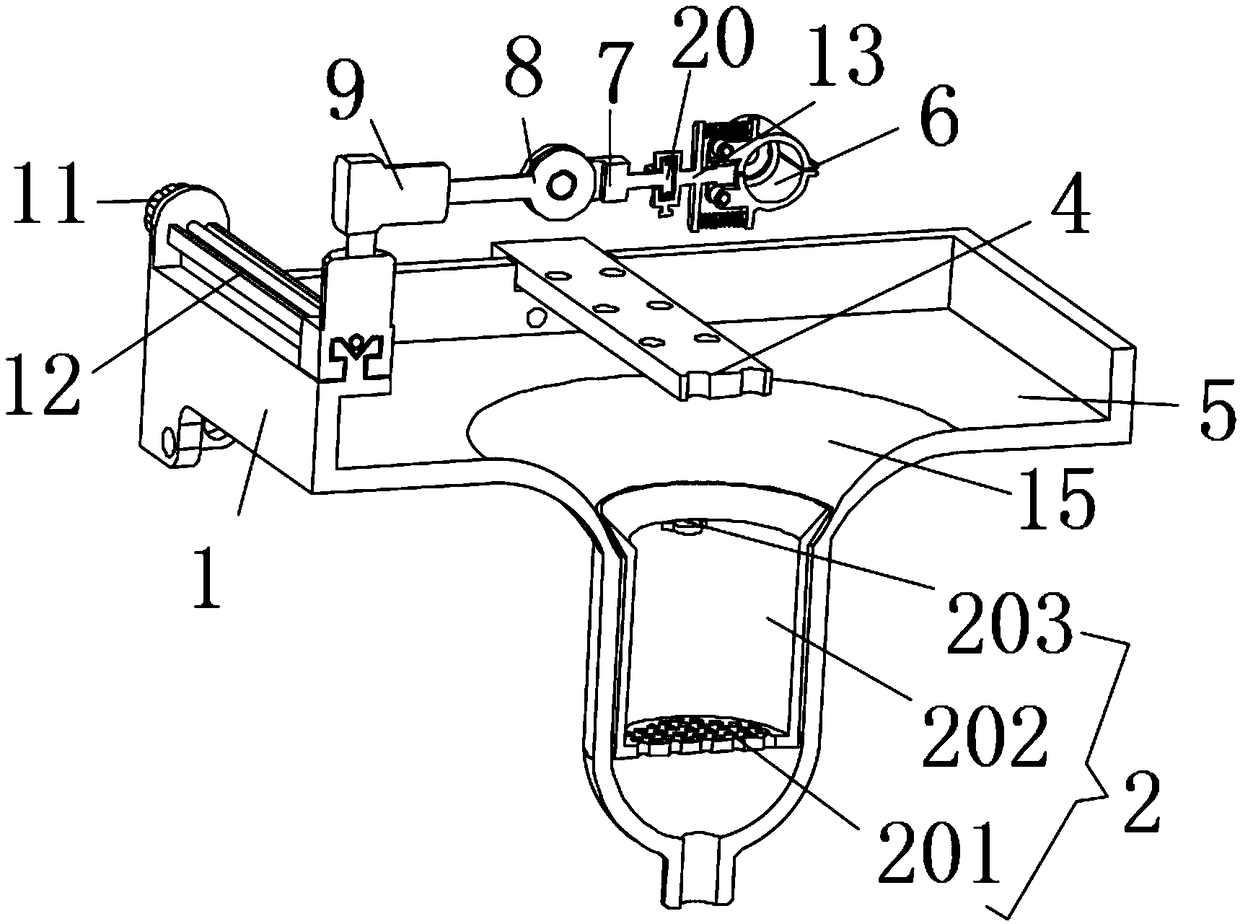

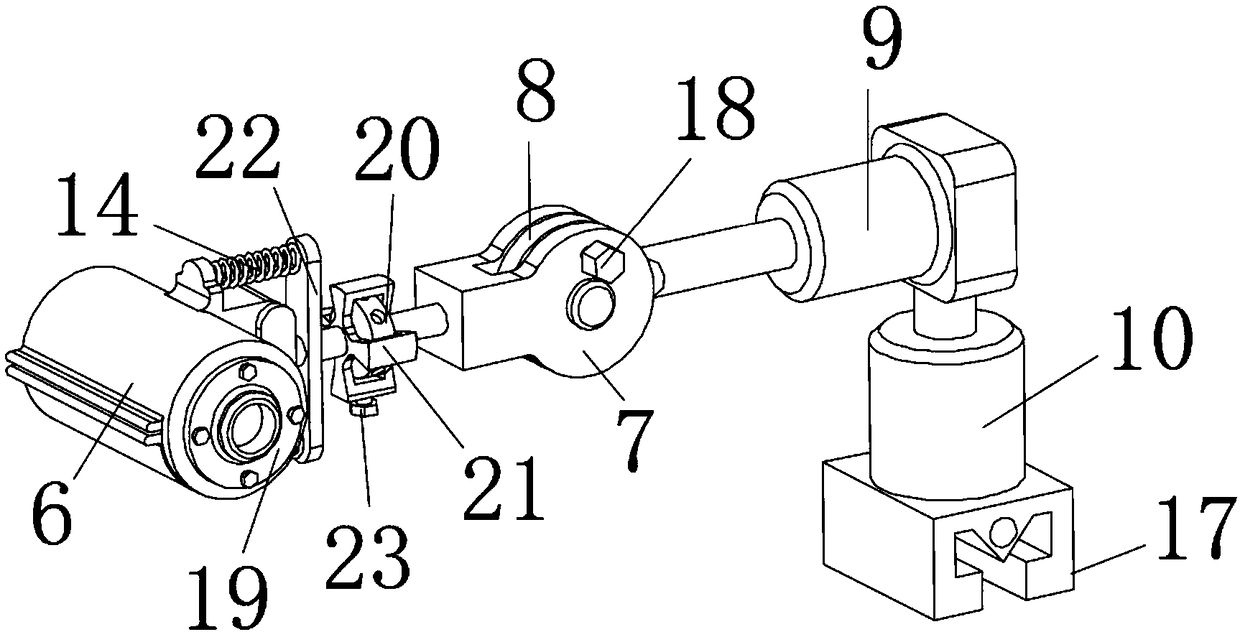

[0018] See Figure 1 to Figure 4 , The present invention provides a technical solution: a drilling machine metal chip recovery device, the base 1, the base 1 is provided with a liquid storage tank 5, and the base 1 is integrally formed with an arc-shaped collecting groove 15 and an arc-shaped collecting groove 15 A collection tube 3 is integrally formed below, and a drain pipe 16 is fixedly installed below the collection tube 3, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap