Double proportional-integral control method for pneumatic clutch

A pneumatic clutch, integral control technology, applied in the direction of clutch, mechanical equipment, etc., to achieve smooth start, smooth movement, responsive and stable clutch position adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

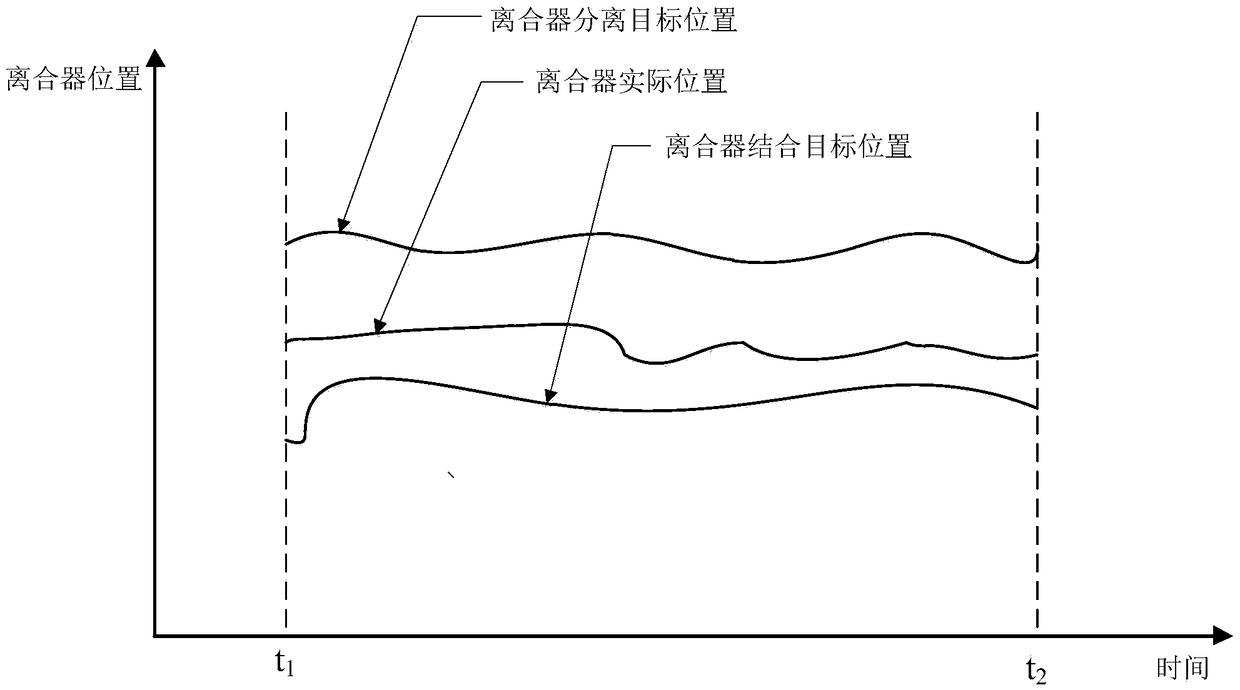

[0017] In the clutch slipping phase, the clutch disengagement target position and the clutch engagement target position are determined through a look-up table algorithm according to the accelerator opening, engine speed and transmission input shaft speed. According to the clutch disengagement target position and the clutch combination target position, the intake valve of the clutch and the exhaust valve of the clutch are controlled simultaneously through the proportional integral control method, and the intake valve and exhaust valve of the clutch work at the same time, so that the clutch is separated and released at the same time. Combine control.

[0018] In the clutch disengagement control process, according to the clutch disengagement target position, the clutch intake valve is controlled by the proportional integral control method, and the proportional coefficient P 1 According to the difference between the clutch disengagement target position and the clutch actual positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com