Automatic test device for durability of folding mechanism in use performance of folding bed

A technology of automatic testing device and folding mechanism, applied in the testing of machine/structural components, testing of mechanical components, measuring devices, etc., can solve the problems of physical exertion, complicated folding action, inability to perform continuous testing and counting, etc. Guaranteed reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

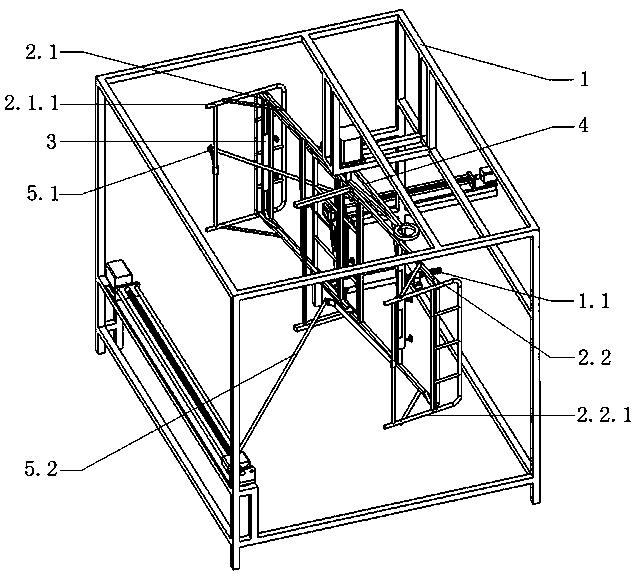

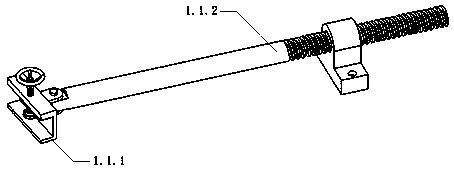

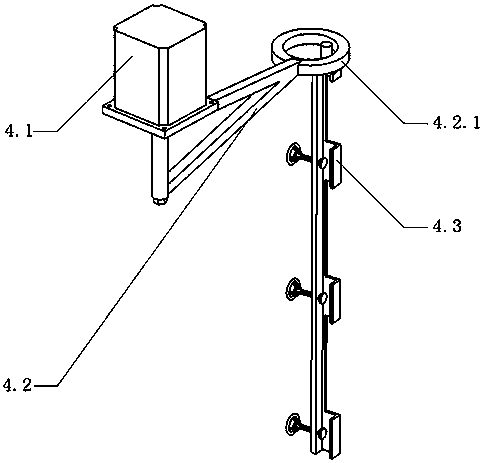

[0024] see figure 1 , which is a structural schematic diagram of an automatic test device for the durability of the folding mechanism in the use performance of the folding bed of the present invention. The automatic test device for the durability of the folding mechanism in the use performance of the folding bed of the present invention includes: a bed driving part 4 and a bed leg driving part 5; the folding mechanism 2 of the folding bed is fixed on the frame 1 by one of the bed parts It is used as a fulcrum for other parts to be extended and stacked; the bed driving part 4 is installed on the frame 1, and is used to drive other bed parts to complete the folding action with the fixed bed part 2.1 as the fulcrum; The bed leg driving part 5 is installed on the frame 1, and is used to drive the bed leg 2.1.1 of the fixed bed part 2.1 to complete the retracting action around the fixed bed part 2.1, and to drive the bed leg 2.2.1 of the movable bed part 2.2 The movable bed parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com