A seesaw capable of improving safety performance

A technology of safety performance and seesaw, applied in the field of seesaw, can solve the problem of safety performance that two children cannot play together, achieve the effect of preventing accidental falling and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

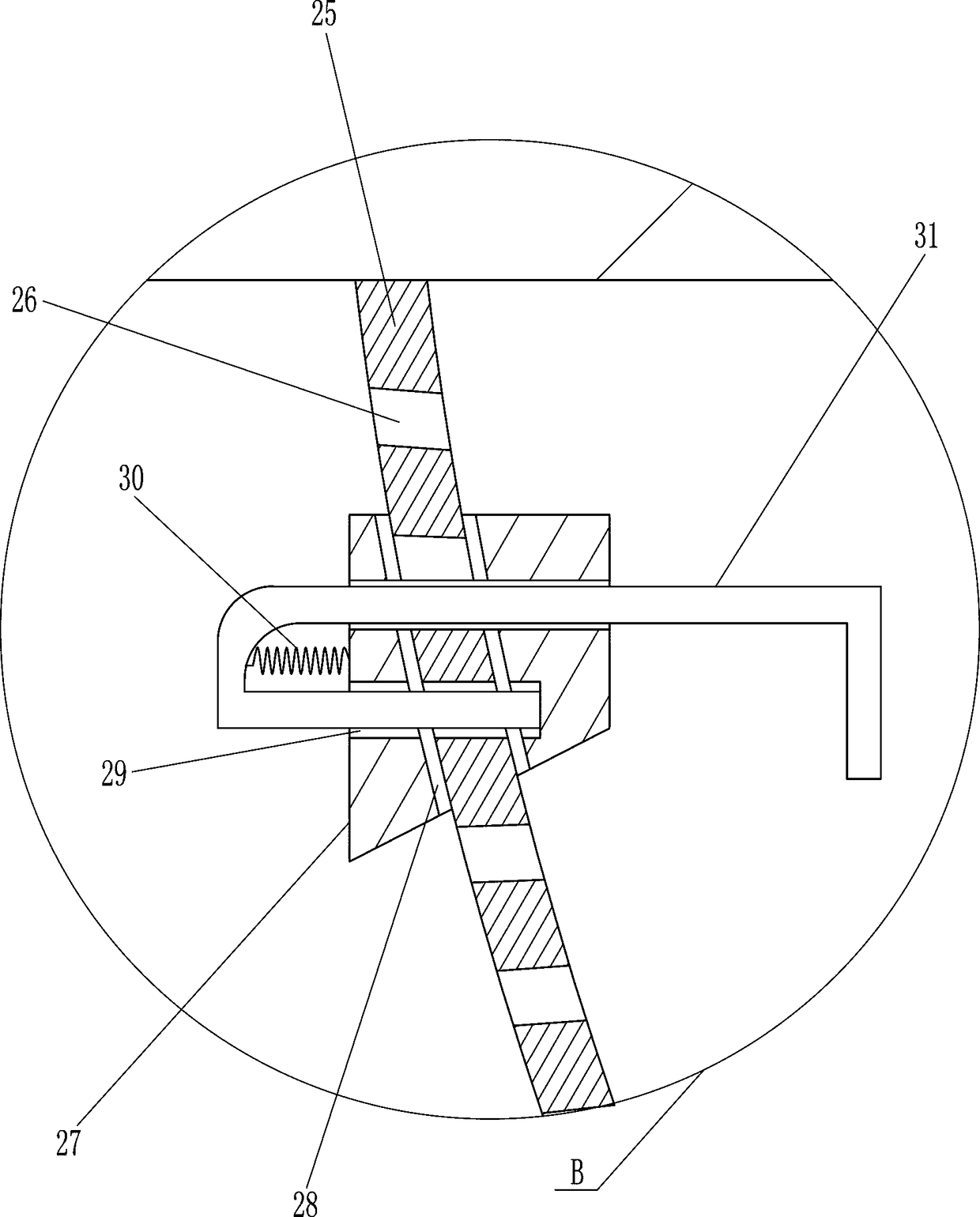

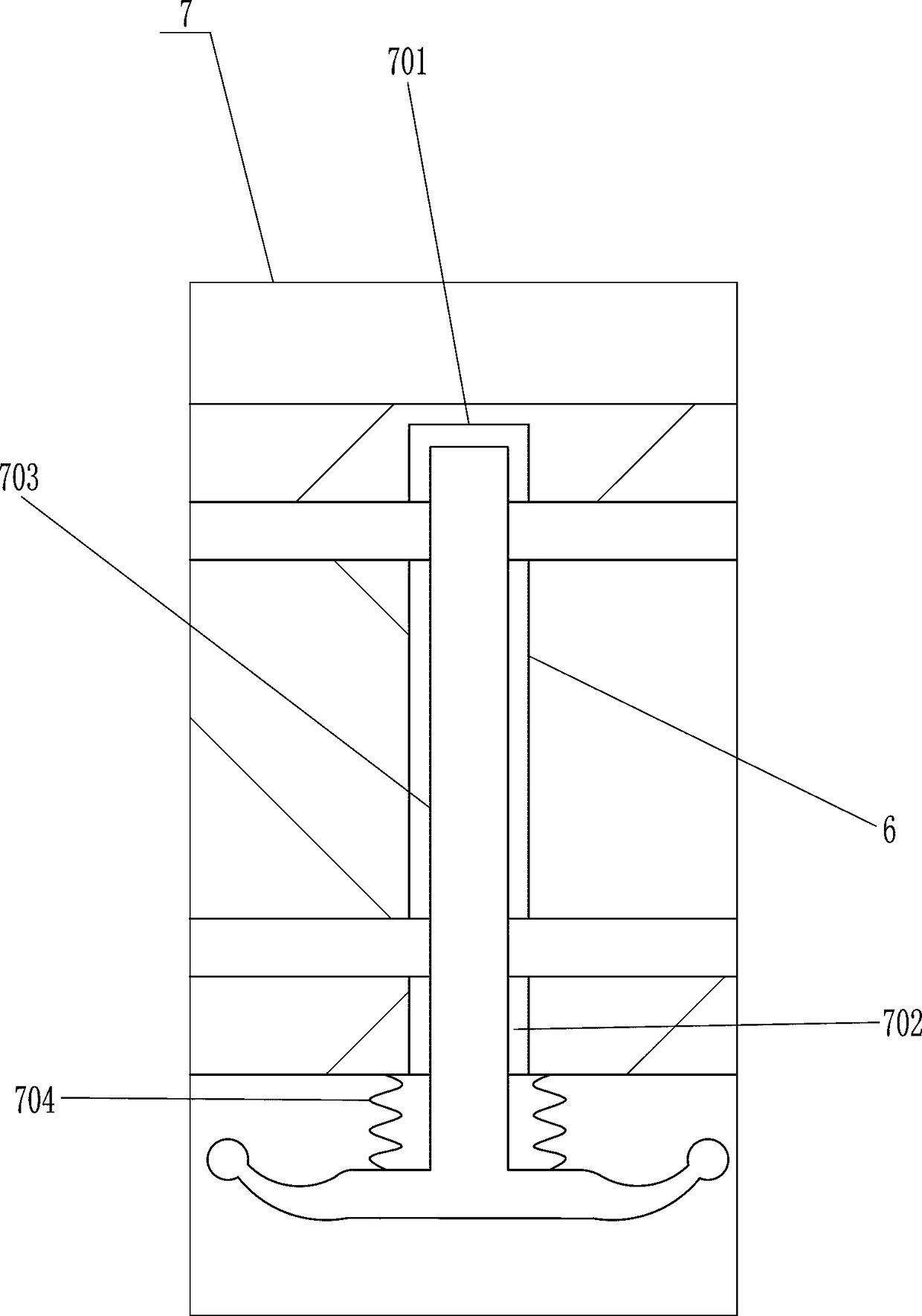

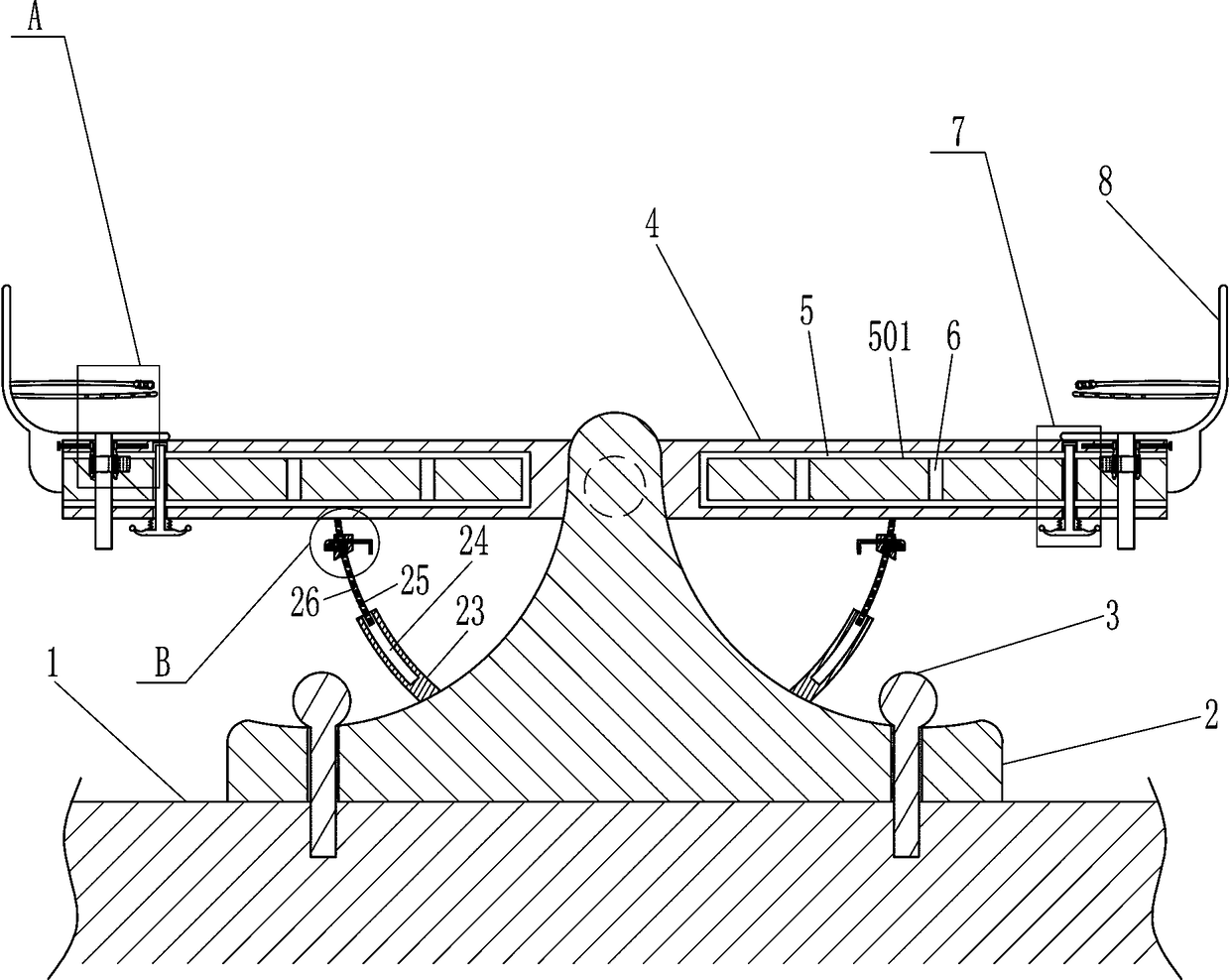

[0020] A seesaw that improves safety features such as Figure 1-4As shown, it includes support 2, bolt 3, swing bar 4, moving bar 501, adjustment mechanism 7, seat plate 8, rear safety belt 9, return-shaped block 10, cross bar 12, front safety belt 13 and round head card The rod 14 and the support 2 are fixed on the ground 1 through the bolts 3 on the left and right sides. The upper part of the rear side of the support 2 is rotatably connected with the swing rod 4, and the left and right parts of the swing rod 4 are provided with elongated holes 5. 5 is inserted with a moving rod 501, and a plurality of first sockets 6 are evenly opened on the moving rod 501, and an adjustment mechanism 7 is inserted outside the moving rod 501, and the adjustment mechanism 7 includes a first insertion rod 703 and a first spring 704, There are grooves 701 on the top and outside of the elongated holes 5 on the left and right sides, and first through holes 702 are formed on the left and right sid...

Embodiment 2

[0022] A seesaw that improves safety features such as Figure 1-4 As shown, it includes support 2, bolt 3, swing bar 4, moving bar 501, adjustment mechanism 7, seat plate 8, rear safety belt 9, return-shaped block 10, cross bar 12, front safety belt 13 and round head card The rod 14 and the support 2 are fixed on the ground 1 through the bolts 3 on the left and right sides. The upper part of the rear side of the support 2 is rotatably connected with the swing rod 4, and the left and right parts of the swing rod 4 are provided with elongated holes 5. 5 is inserted with a moving rod 501, and a plurality of first sockets 6 are evenly opened on the moving rod 501, and an adjustment mechanism 7 is inserted outside the moving rod 501, and the adjustment mechanism 7 includes a first insertion rod 703 and a first spring 704, There are grooves 701 on the top and outside of the elongated holes 5 on the left and right sides, and first through holes 702 are formed on the left and right si...

Embodiment 3

[0025] A seesaw that improves safety features such as Figure 1-4 As shown, it includes support 2, bolt 3, swing bar 4, moving bar 501, adjustment mechanism 7, seat plate 8, rear safety belt 9, return-shaped block 10, cross bar 12, front safety belt 13 and round head card The rod 14 and the support 2 are fixed on the ground 1 through the bolts 3 on the left and right sides. The upper part of the rear side of the support 2 is rotatably connected with the swing rod 4, and the left and right parts of the swing rod 4 are provided with elongated holes 5. 5 is inserted with a moving rod 501, and a plurality of first sockets 6 are evenly opened on the moving rod 501, and an adjustment mechanism 7 is inserted outside the moving rod 501, and the adjustment mechanism 7 includes a first insertion rod 703 and a first spring 704, There are grooves 701 on the top and outside of the elongated holes 5 on the left and right sides, and first through holes 702 are formed on the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com