Spring seat sleeve loading mechanism of pencil core combination machine for mechanical pencils

A technology of mechanical pencils and combination machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This specific embodiment is only an explanation of the present invention, and it does not limit the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as the rights of the present invention are used All claims are protected by patent law.

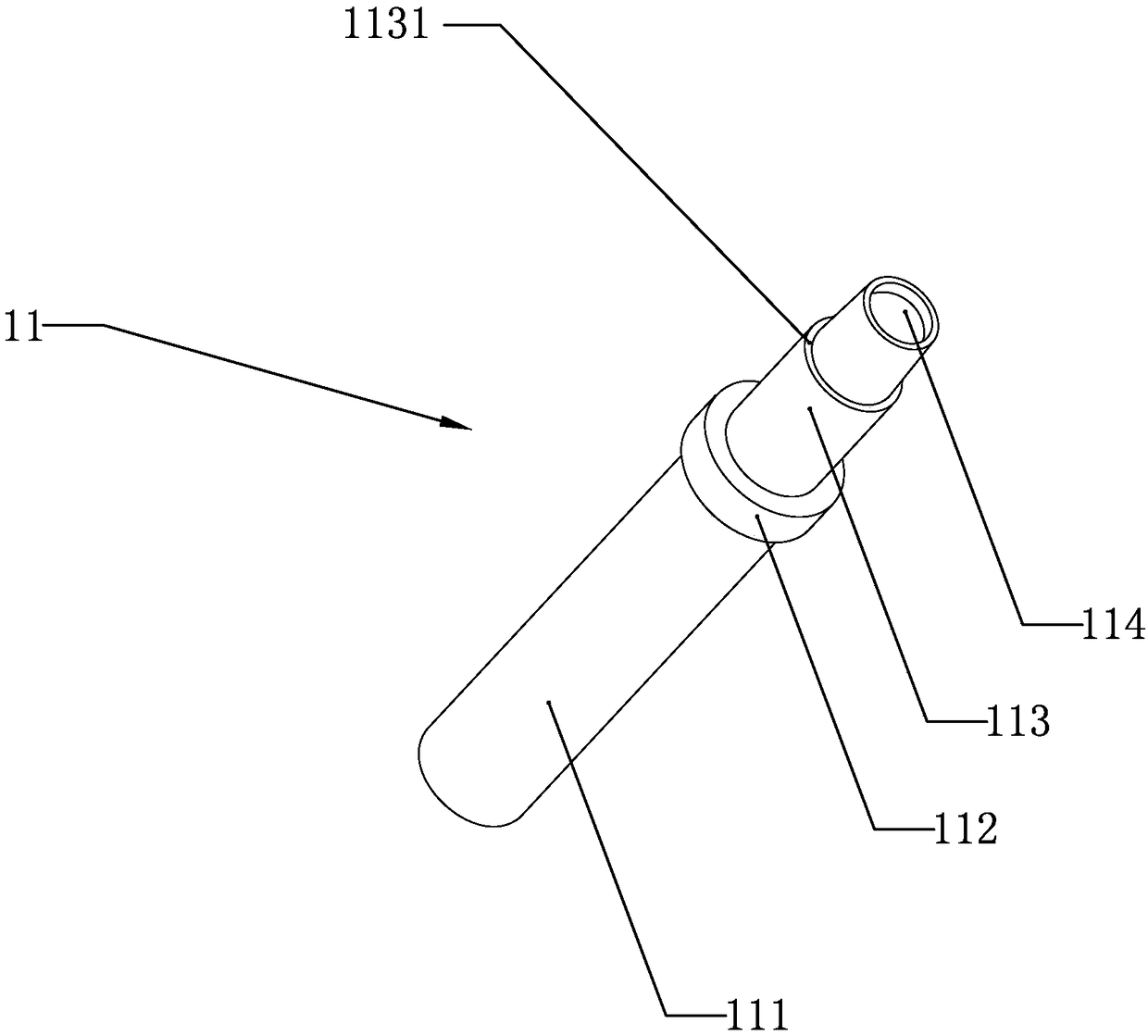

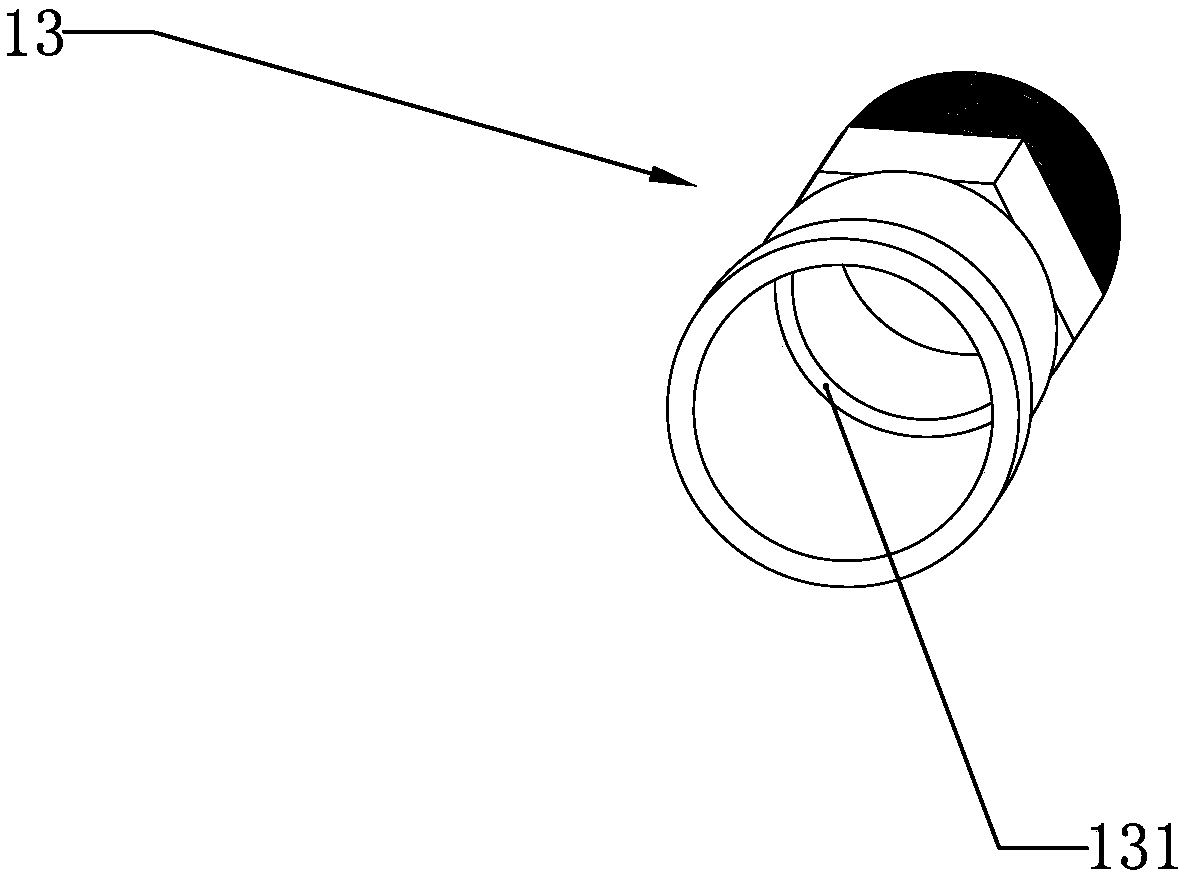

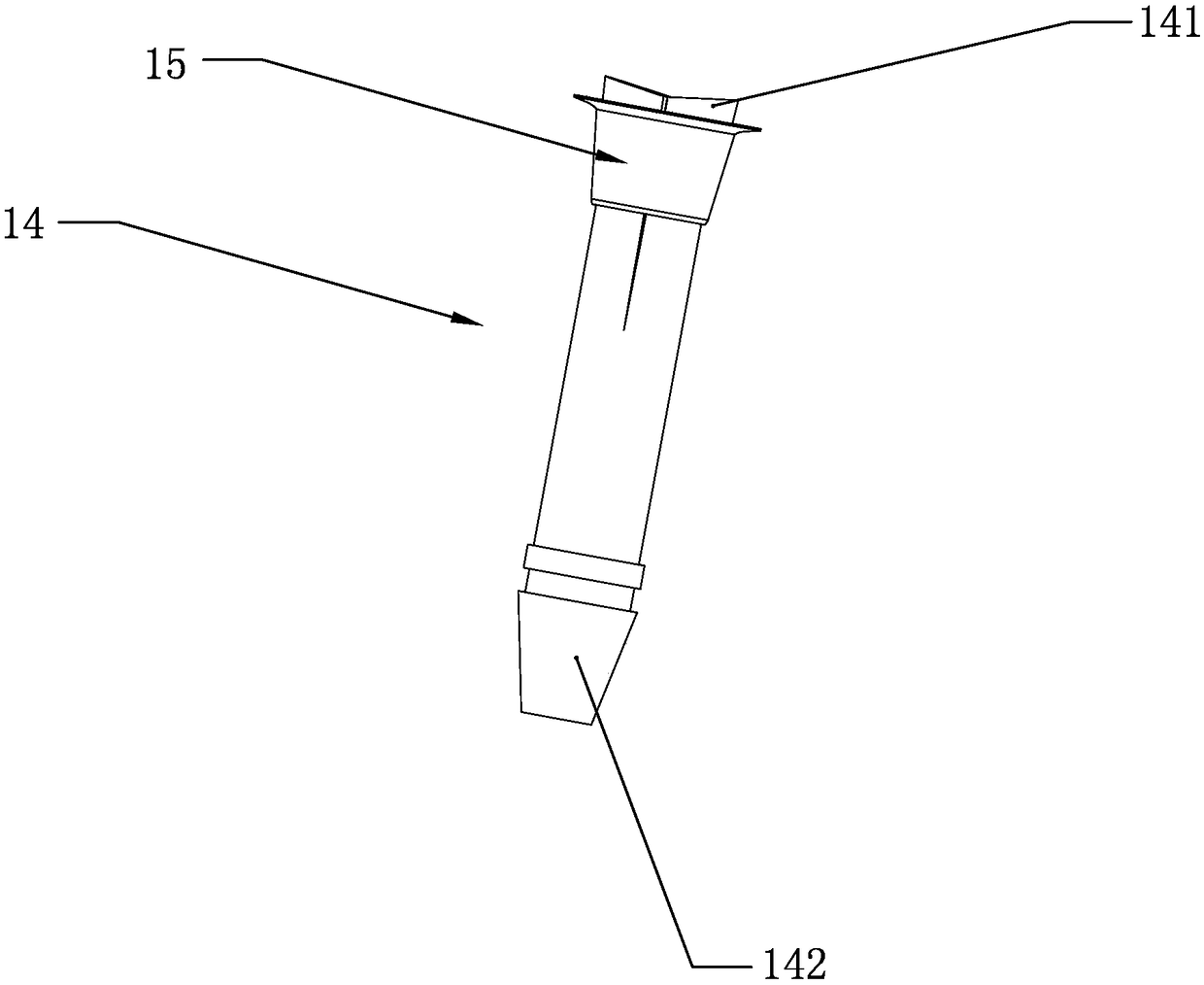

[0021] see attached Figure 1-7 , the feeding mechanism of the spring seat cover 13 of the refill combination machine of a mechanical pencil disclosed in the present invention includes a vibrating plate 5, a conveying guide rail 2, a feeding mechanism 3, a pressing rod 6, a guide assembly 7, a detection mechanism 4, a driving power Source 8, the conveying guide rail 2 is arranged on the upper end of the feeding mechanism 3, the conveying guide rail 2 is provided with a conveying guide groove 21, the guide assembly 7 is arranged at the front end of the feeding mechanism 3, the pressing rod 6 Connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com