A laser marking method

A laser marking method and laser marking machine technology, which are applied in the field of laser marking, can solve problems such as burrs on trademarks, color difference, and crooked label stickers, and achieve the effect of improving installation stability and avoiding shaking of the marking head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A laser marking method of the present invention comprises the following steps:

[0034] A. Install a positioning device with mounting holes 3 on the surface of the workpiece;

[0035] B. Spray the glaze from the mounting hole 3 of the positioning device in step A to the surface of the workpiece;

[0036] C. Install the laser marking machine on the mounting hole 3 of the positioning device, and start the laser marking machine for marking. In this embodiment, the laser marking machine adopts the BML-1x30-GC laser marking machine of Sernovi Company. When marking, the marking intensity of the laser marking machine is 300%, and the marking speed is 400 mm / s. The standard frequency is 100kHz.

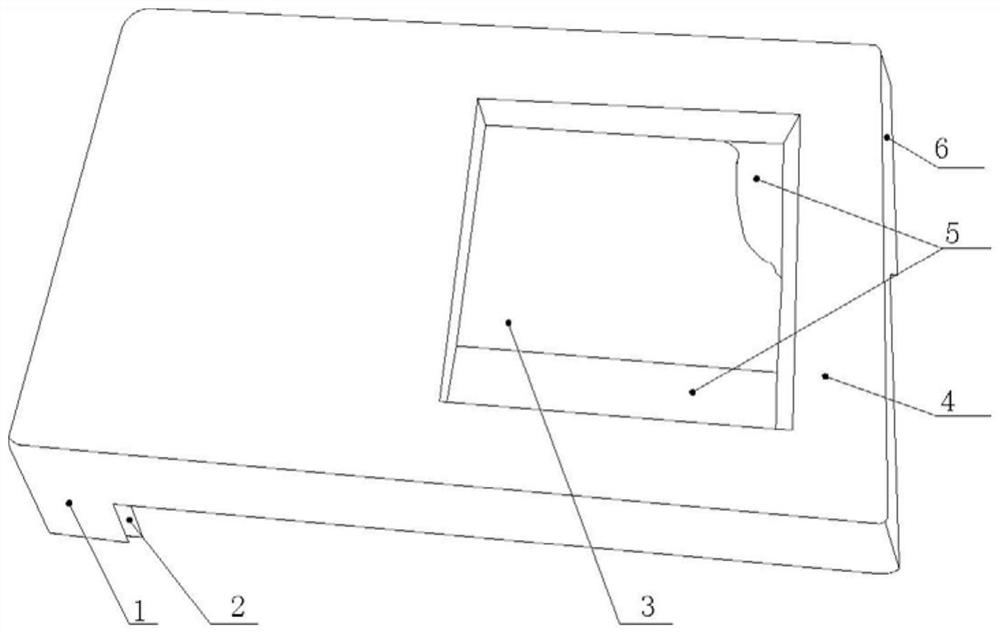

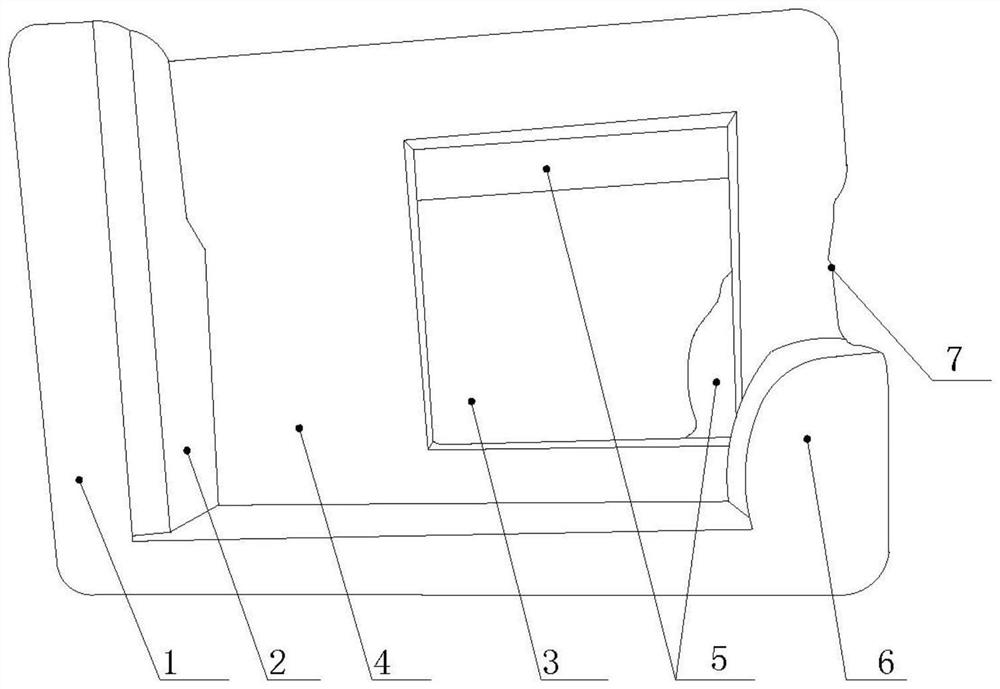

[0037] Such as figure 1 with figure 2 As shown, the positioning device described in step B includes a rectangular positioning body 4, a rectangular mounting hole 3 is provided on the positioning body 4, and an abutment plate 6 is integrally formed on the short side of the right si...

Embodiment 2

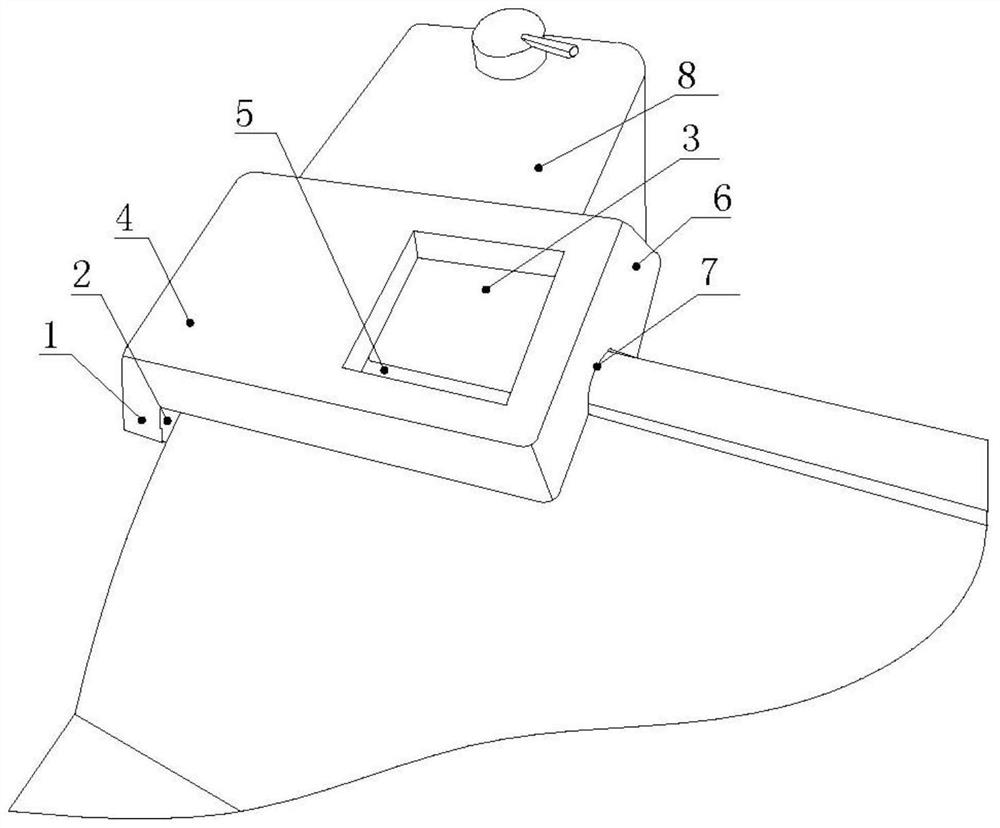

[0045] The difference between this embodiment and Embodiment 1 is that, as Figure 5 As shown, the interior of the gasket 9 in this embodiment is hollow to form a cavity 13, and a spring 11 is installed vertically in the cavity 13 to increase the elasticity of the gasket 9, and two suction holes 12 are provided at the bottom of the gasket 9 , The four outer walls of the gasket 9 are also provided with suction holes 12 , and each suction hole 12 on the gasket 9 communicates with the cavity 13 .

[0046] During specific use, put the end of the gasket 9 with the air suction hole 12 downward into the installation hole 3, and then manually press the gasket 9 vertically downward, so that the gasket 9 shrinks, and the spring 11 in the gasket 9 also Compressed, at this time the gas in the cavity 13 is squeezed out from the suction hole 12; the volume of the compressed gasket 9 becomes smaller, and the depth of the jack 10 on it also becomes smaller, which is convenient for inserting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com